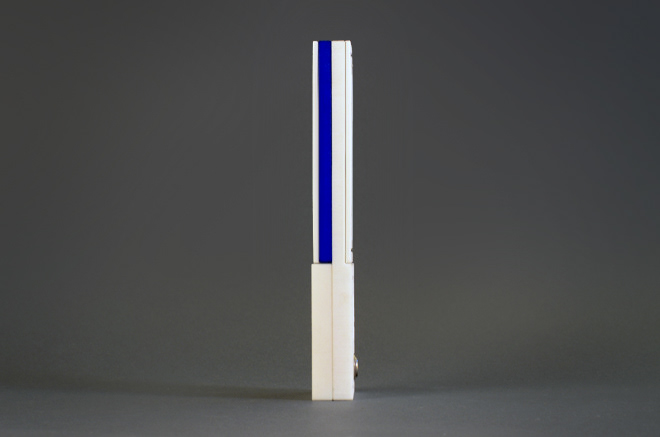

The Ribbon Microphone transducer design has been in service for over 80 years. The design has been hailed to reproduce more properly to that of what a human organic ear hears than its more complex active transducer counterparts (such as the Dynamic or Condenser designs).

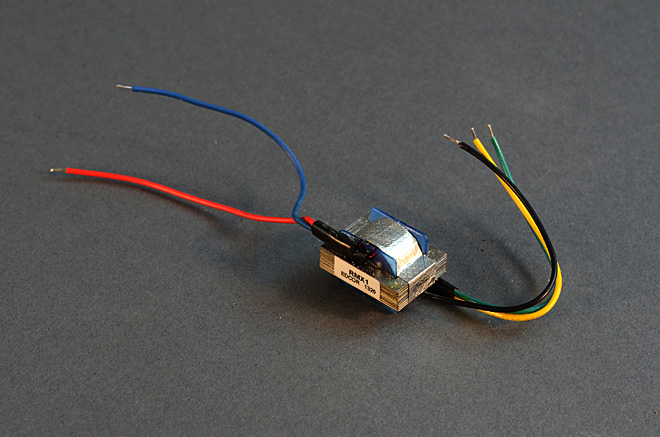

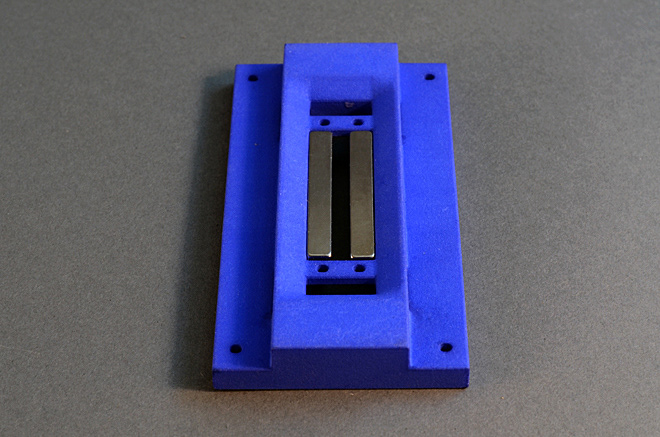

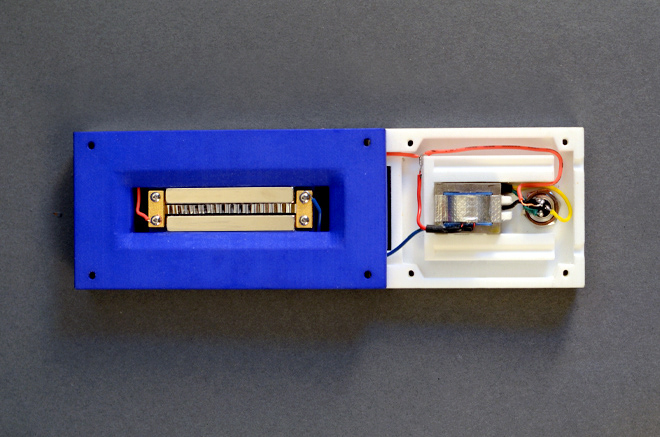

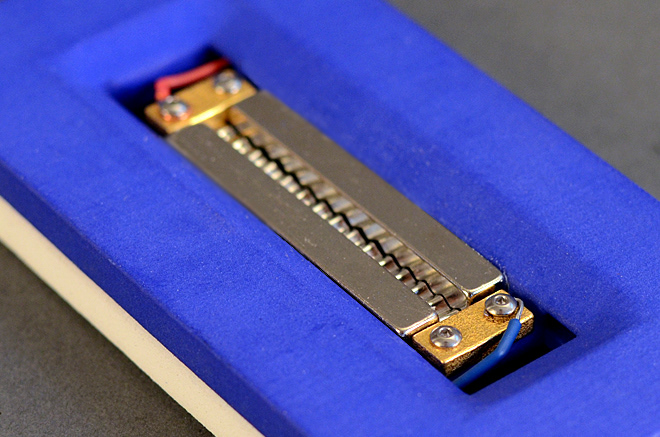

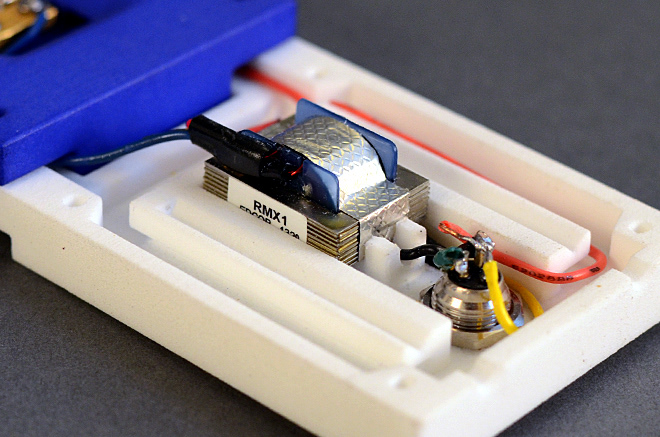

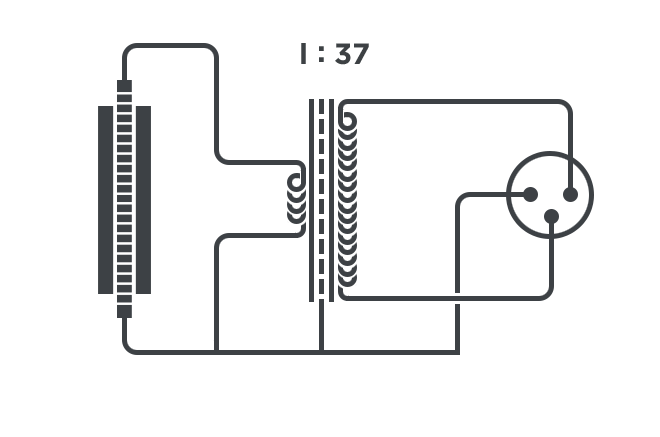

At the heart of a Ribbon Microphone is a thin (two thousands of an inch thick) piece of corrugated aluminum that sits in between a very strong magnetic field. When the foil is moved inside the strong magnetic field, the effect of "Electromagnetic Induction" produces an electrical signal that runs through the aluminum conductor. Vibrations from the environment (sounds) physically translates into the aluminum ribbon allowing for a signal to be generated. This signal is so incredibly weak, (a quarter of a millivolt) an impressive transformer has to step up the voltage to a more usable level. In this case, a ratio of 1:37 is required before even reaching a small signal microphone preamplifier.

Because of the delicate nature of a thin ribbon transducer, the sonic characteristics mimic more closely how our ears perceive sound resulting in a more detailed, warm, & natural tone when compared to other transducer designs.

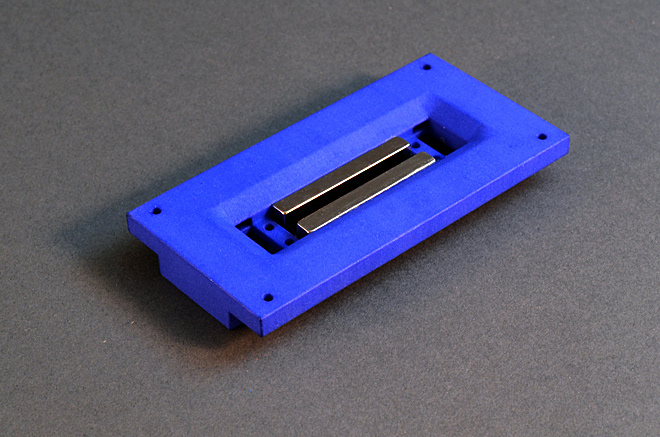

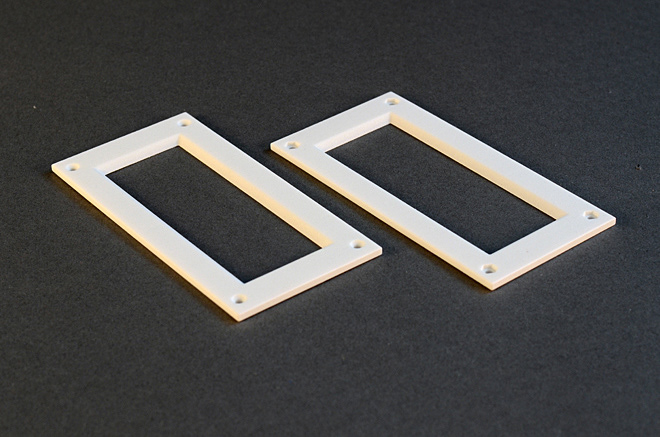

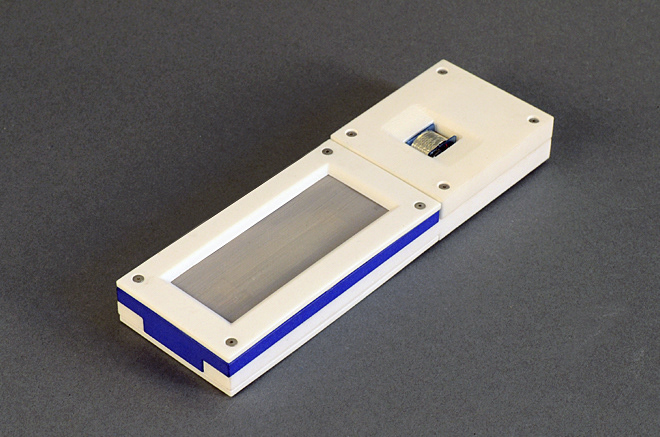

Because of their frail nature, Ribbon microphones require more enclosure and material engineering for better acoustic and longer lasting performance. The Ribbon microphone typically has a high price point and is out of reach for most users because of these engineering requirements.

The requirements for my Ribbon Microphone design are: (1) no compromise sonic attributes (2) Affordability (3) low production & assembly time.

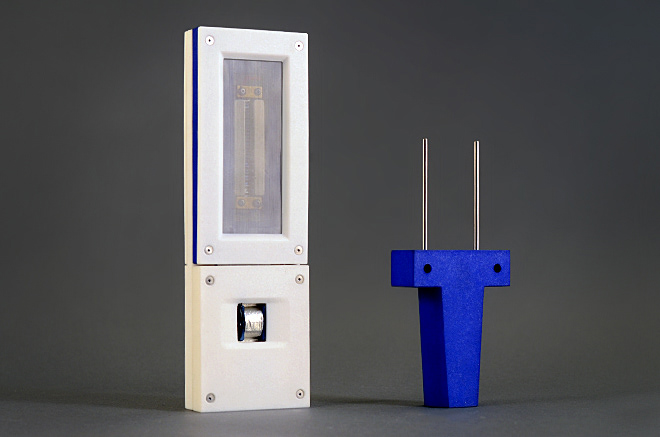

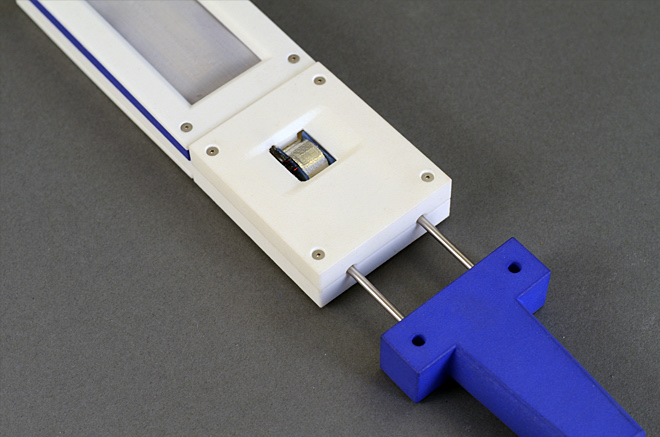

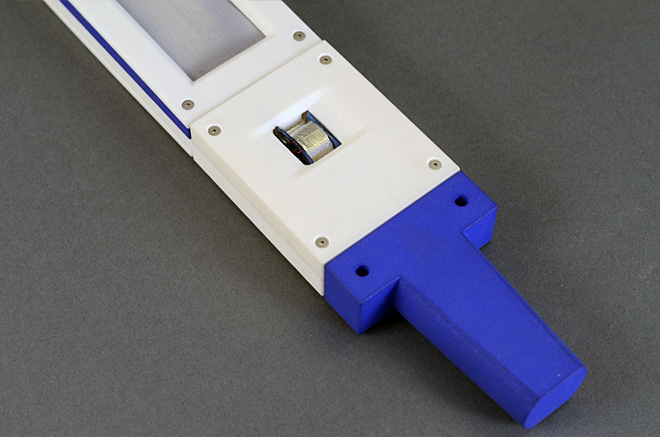

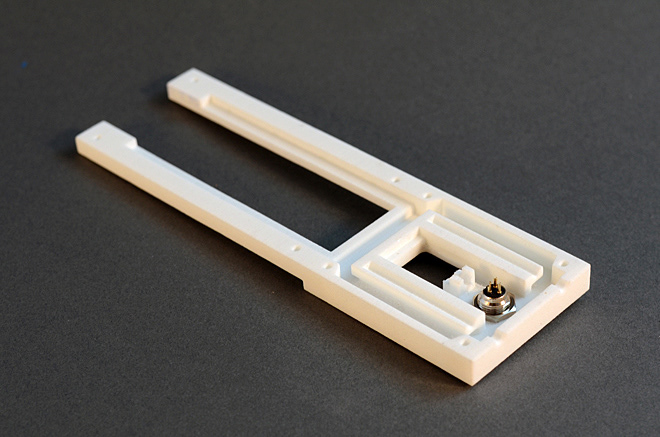

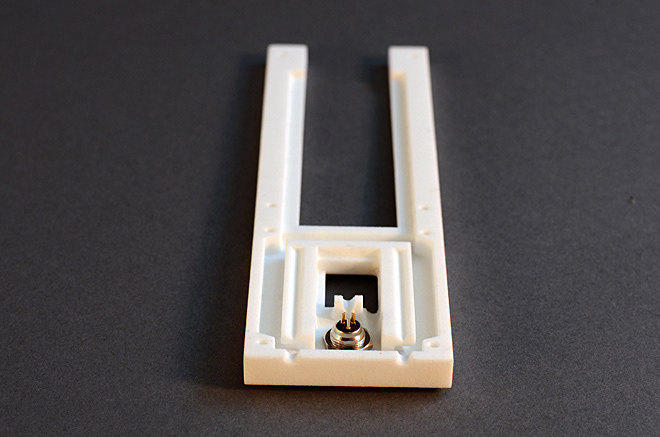

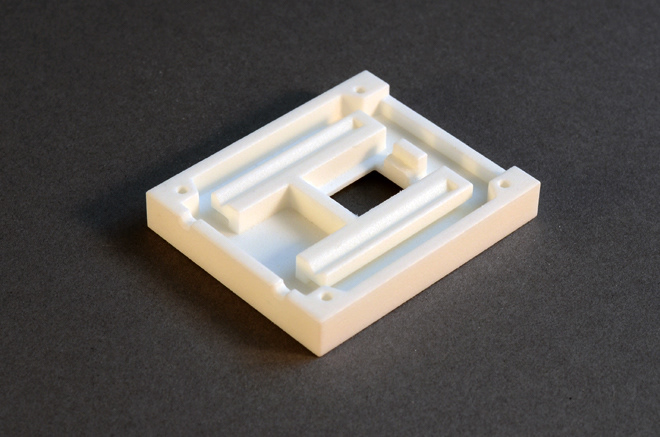

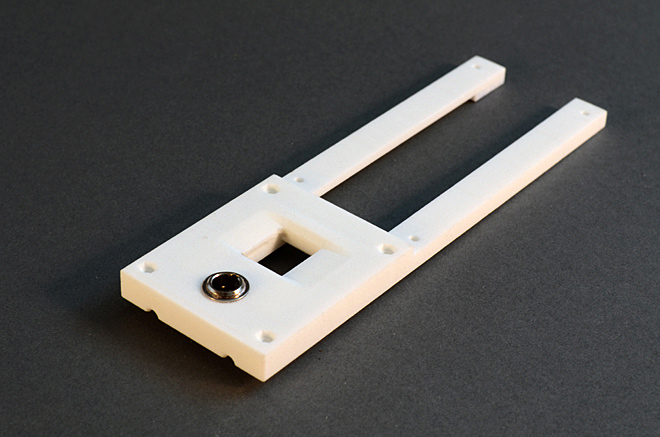

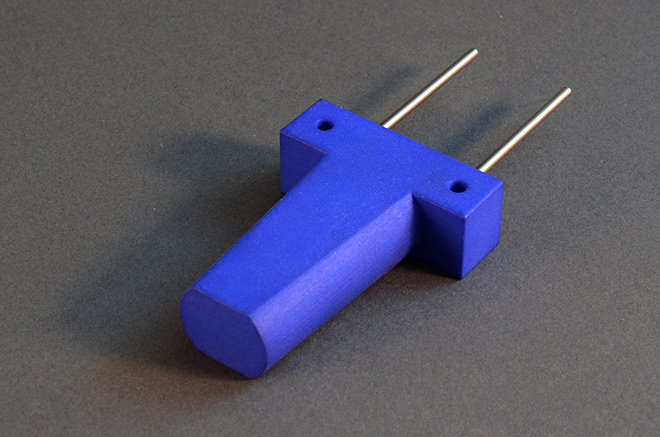

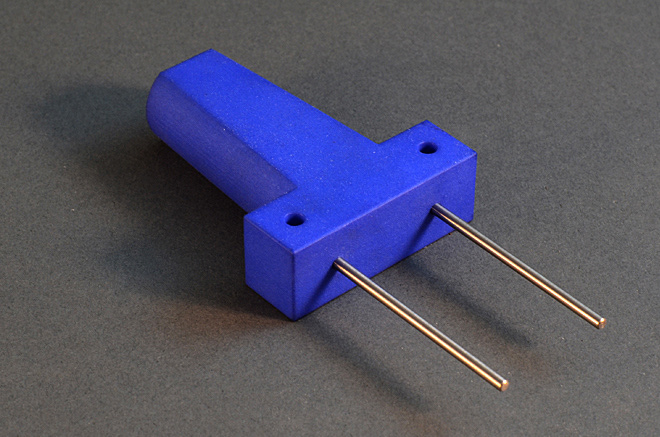

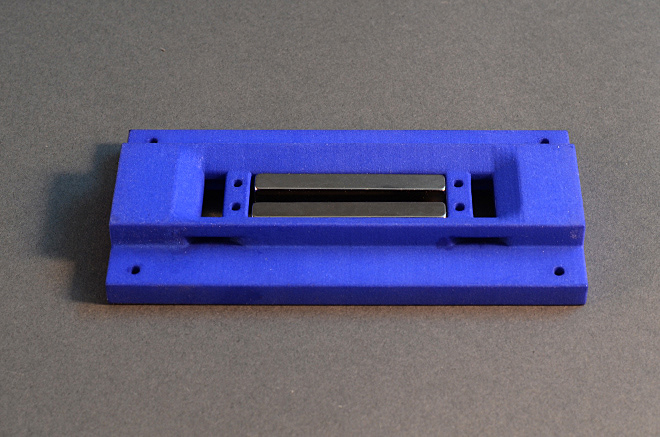

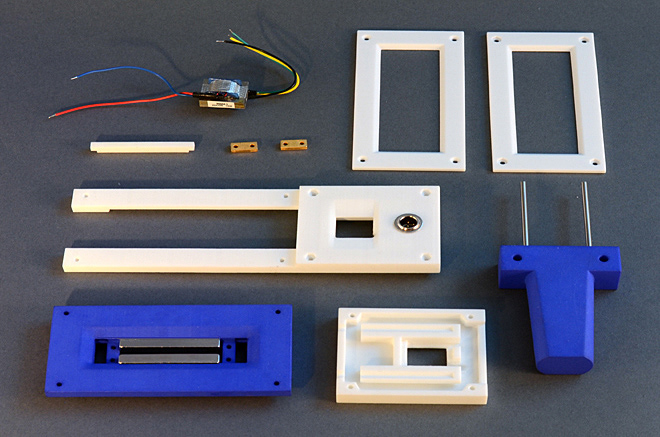

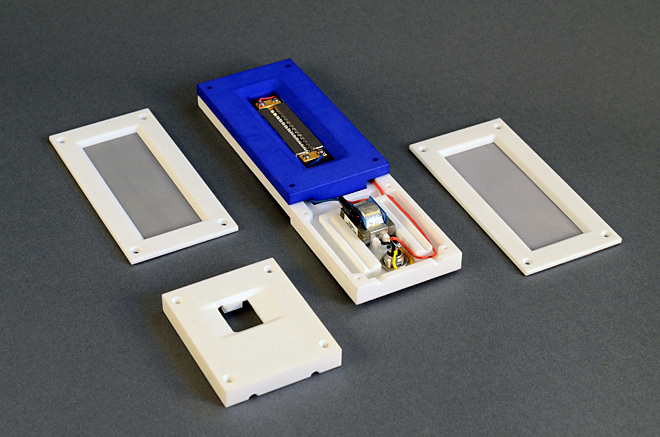

This led me to investigating in robust 3D printing solutions. The method I selected was Stereolithography Nylon for its resolution and material structural gains when compared to Fused Deposition Modeling (FDM).

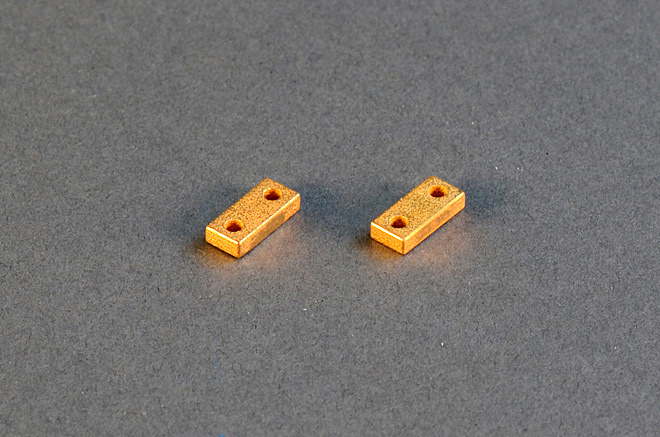

The Gold Clamp Contacts that hold down the Ribbon also act as the signal terminals for the hookup wire to attach to. These blocks are 3D printed sand cast stainless steel and bronze infused. Later it is Gold plated for electrical conductivity reasons.

When Properly ran though high gain low noise preamplifiers, the Stereolithography Ribbon Microphone competes with other commercially available Ribbon Microphones. The S.R.M. Produces the smooth warm timber and crystal clear voices that make Ribbon Microphones loved synonymously by artists and engineers alike.

The Nylon body has no audible degradation to the signal.

Printed at Shapeways®