Astronauts have many concerns while in orbit. The comfort of their gloves is constantly on their mind because the forces at play are very difficult to resolve and counteract on a scale as small as the hand. Creases that are strengthened by the pressure of a simulated atmosphere prevent circulation in the astronauts hand, which causes nail delamination, fatigue, and general discomfort.

I decided to take on the task of redesigning the astronaut glove through an exploration of material, connections methods, and form.

the tools of the trade - seam construction samples, a glove template, a rubber "bladder" which maintains the airtight seal, and a metal ring that affixes the prototype to our test chamber.

I became very comfortable throughout this project with the iterative process. Over the span of 5 weeks I researched, designed, and fabricated 8 gloves. I learned that not only is it important to prototype often, but to also prototype different aspects of the project, to gain a more encompassing view of the object/experience one is designing.

Here are all the prototypes, except for the final, laid out together in order from left to right. Please see below for an explanation of my process.

This is the first glove I mede. Note the poor seam construction, and the use of one materal across the entire glove. It is bulky and does not bend in the right way.

The first prototype, with darts added on the back

my first prototype, a knitweare glove. Here it is being tested in our vaccuum chamber. Note the excessive bulbous palm area and the lack of a natural precurve.

This is the second prototype. I added pleats along the knuckles to ease the bending of the joints. This method worked very well. I also added a tape applique to strenghten the palm.

This is the second prototype in the test chamber. Here i have added pleats on the fingers to allow them to bend more easily, expanded the sleeve, and added tape appliques to reinforce the palm and allow for more bending of the joints.

The third glove. This frankenstein approach was a method to rapidly test several different finger methods, however a poor choice of material (canvas) got in the way of this prototype from helping me beyond basic understanding of how the different fingers would bend.. From left to right: Lines of non-extension - this finger worked well, but the accumulation of excess fabric was uncomfortable, Button-hole joint - this finger worked well because it allowed the joint to bend as much as with a pleat, but without the excessive accumulation of fabric, box-pleat joint - this worked just slightly not as well as wht line of non-extenion finger, which also had box pleats in it, plain finger - this one obviously failed miserably, thumb - I tried out a new thumb pattern geometry, which although bad, was a step in the right direction.

The fourth prototype focused on the refinement of the button-hole joint and selective fusible interfacing. I used this technique to selectively bond a knit to a woven rip-stop fabric to create a strong, yet comfortable material that I could select to bend in different places by not included the woven fabric.

While testing the fourth prototype, the seam on the side blew out. This was due to a weak seam construction, and the use of a material - rip-stop - that easily tears. You can see the dried interfacing in between the two layers.

A constant conversation with one's material - it's limitations and it's preferences was a huge lesson that I learned from this project. A designer must always be listening to his/her material and accounting for its shortcomings, but more importantly capitalizing on its strengths.

The fifth prototpe built on concepts fronm the first including a revised thumb, "boomerang gussets" and suchlike. I did not include the button-hole joints to save time because my goal with this prototype was to experiment with the carbon-fiber palm restraint.

Palm restraint placement.

Carbon-fiber palm restraint - formed to my own hand specifically and then machineed to allow for maximum flexibility

This is the inside of the final prototype. Note the reinforcement of the dart with "x"s sewn onto the seam to locate it. Also note the tape applique to prevent the glove from bending out too much, and the knit fabric applied to the inside, which forms the precurve on the individual fingers. The silver fabric you see here is a nickel-based fabric that is good for the skin in harsh environments.

This is the final prototype. It features a bound seam along the outside for added robustness of the joint. Here I am testing the flexibility of the palm restraint.

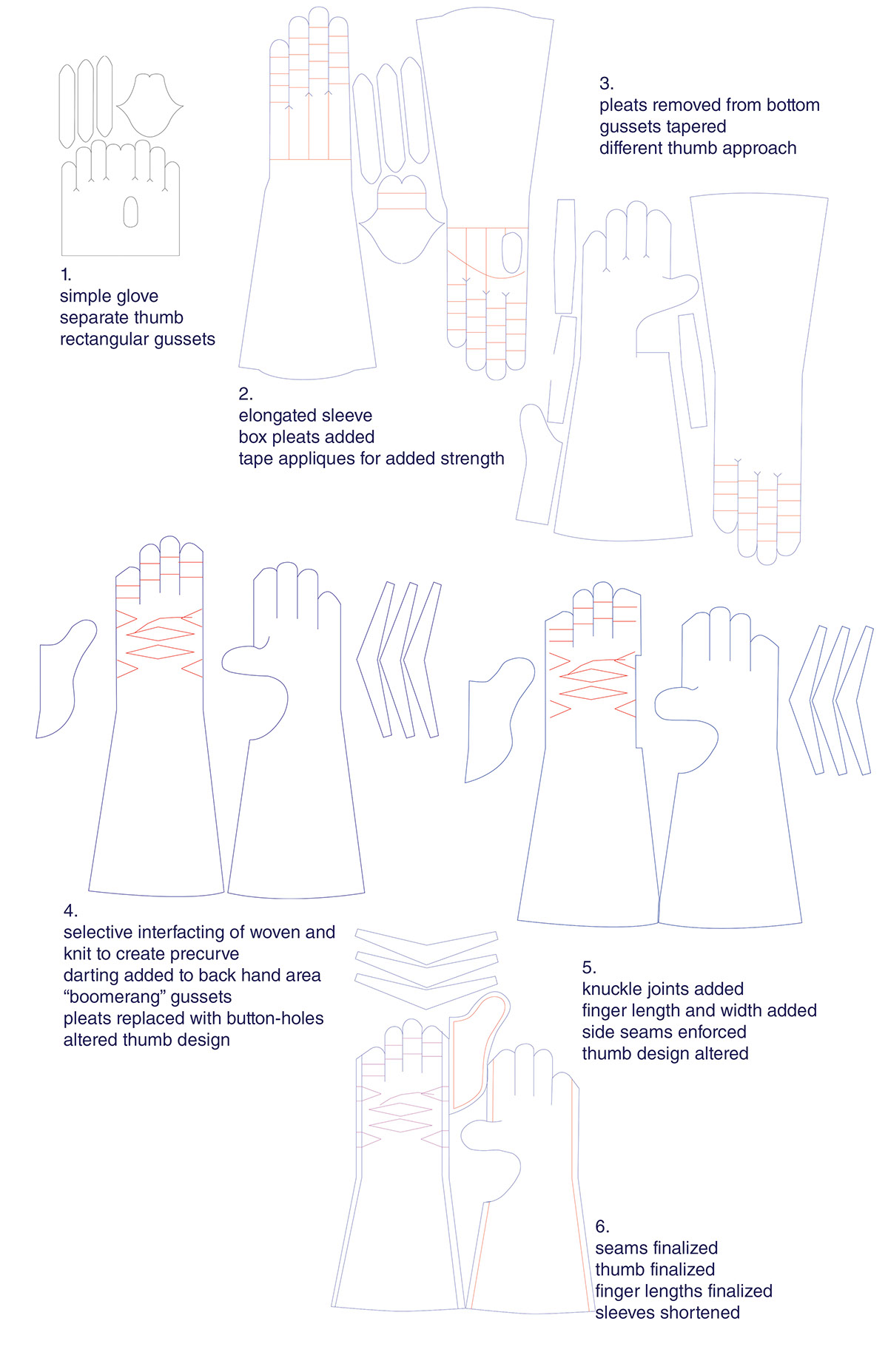

One of the most important things that I learned through this project was the about the constant interplay between working in two dimensions and three. Below, find a charting of my different pattern designs, and how they evolved throughout the course of the process. All patterns were drafted by hand, then later scanned and vectored for posterity. Please contact me if you would like access to any of the patterns for your own prototyping purposes.

Take note here of the carbon fiber palm restraint casing, and how it allows for flexibility in the hand.

The final prototype, sewn by hand. Although my primary focus was structure throughout the entirety of the project, I ended up honing in on my aesthetic a lot as well. I let the construction inform the details I would push and pull to design a visually as well as functionally resolved glove.