Final table. Detail View.

Materials: African Mahogany, Ash, Zippers.

This project was an exercise in teamwork. We were charged to design and fabricate a table with a focus on the connector of our individual modules. Each team member was responsible for making one of the modules from start to finish.

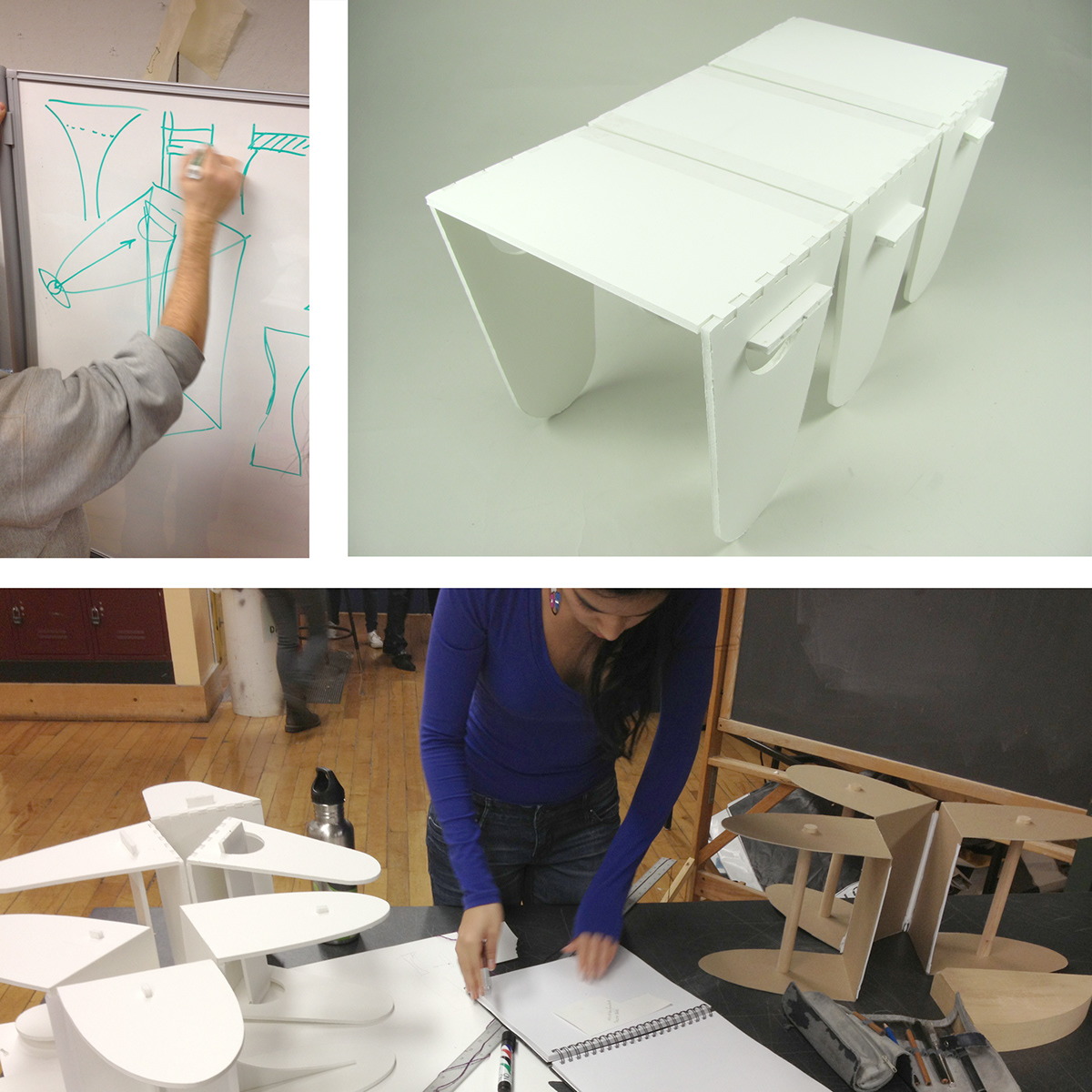

From top-bottom, left-right: Group brainstorming, experimenting with vacuum bag, making sketch models, zipper connector sketch model, leather mimicked live edge sketch models, vel-cro joint sketch model.

Materials: Scrap wood, vel-cro, scrap artificial leather, zipper.

Through thoughtful experimentation with vel-cro, a vaccum bag for lamination, and zipper lamination, we decided that we wanted to explore the potential of using a zipper to connect our modules. The connection was robust, but flexible and fun to use.

Clockwise from top left: Brainstorming on how to design the support for the cantilever, 1/4 scale model, designing with 1/4 scale models.

Materials: Foam-core, chip board.

After we decided to design our table around the zipper connecting method, we created sketch models and orthographics in Adobe Illustrator.

Orthographic projections for full scale table design illustrating the connector.

The most time consuming portion of the project was the construction of the table. Steps we went through included: Gathering materials, milling and dimensioning the wood, laminating the zippers, shaping the wood, cutting joints, glue-ups and hand planing miters onto edges.

Clockwise from top left: Excessive sawdust after milling, more sawdust after milling, clamping up the first panel after milling, all of the glue-ups of dimensioned wood, Sanding final pieces, chiseling finger joints, gluing up the zipper laminations, gluing up the first zipper lamination, putting the pieces together after rough-cutting.

The main advantages of our design are its adaptability to any environment and it's ease of handling. units can be added or taken away depending on what is suitable and it can form a radial orientation if it is placed on it's side and the zippers on the ends are joined. The leg supports extend past the outide of the legs so that in it's secondary form the table is raised from the ground.

Final product. Detail view.

Final product. Detail view.

Final product. Detail view.

Final Product. Orientation 2.

Final Product. Orientation 1.