Precast Concrete - Biergarten Design

Working through a semester with Rachel Rosenberg (RISD M.Arch 2017) in an advanced studio that worked with plaster and concrete to create a new design for a chosen site and program based on prior experimentations. The ending result was an alleyway Biergarten with precast floor slabs that would allow irrigation and regulation of the sloping terrain existing. About 20 pieces of the floor were constructed including other components for its design such as a larger lower gutter system to catch and drain water, a planter system that would allow integration of a passive filtration system and its corresponding retaining wall. As much as this project was about learning precast concrete and its wide variety of uses, it was also a large experimentation of fabric, stiff, one way and two-way stretch. Through this analysis (in the casting of the floor modules), we were able to figure out the best fabric for each situation.

Part I: Initial experimentation

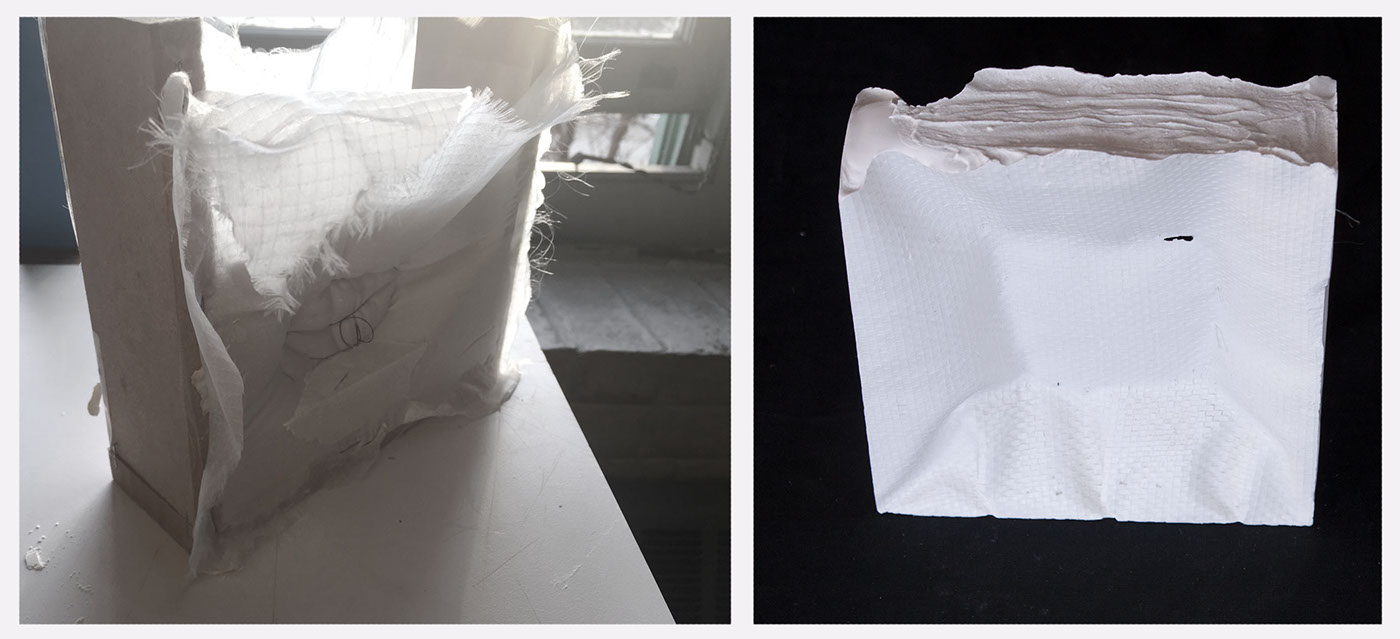

Never working in either plaster or concrete, the first experiments began with fabric as the mediator for precast, either sewing it together to get thinner cross sections in certain areas, or pulling it apart to get extruded edges or spikes.

First week, inspired by Litracon's translucent concrete and the Binecke Library concrete facade, the objective was to see how thin the concrete could be spread to allow light to pass through. In this test, the first flooded and didn't create the thin cross section wanted. In the second test, however, it worked relatively well, allowing a very light ring of light to pass where the sewn edges were.

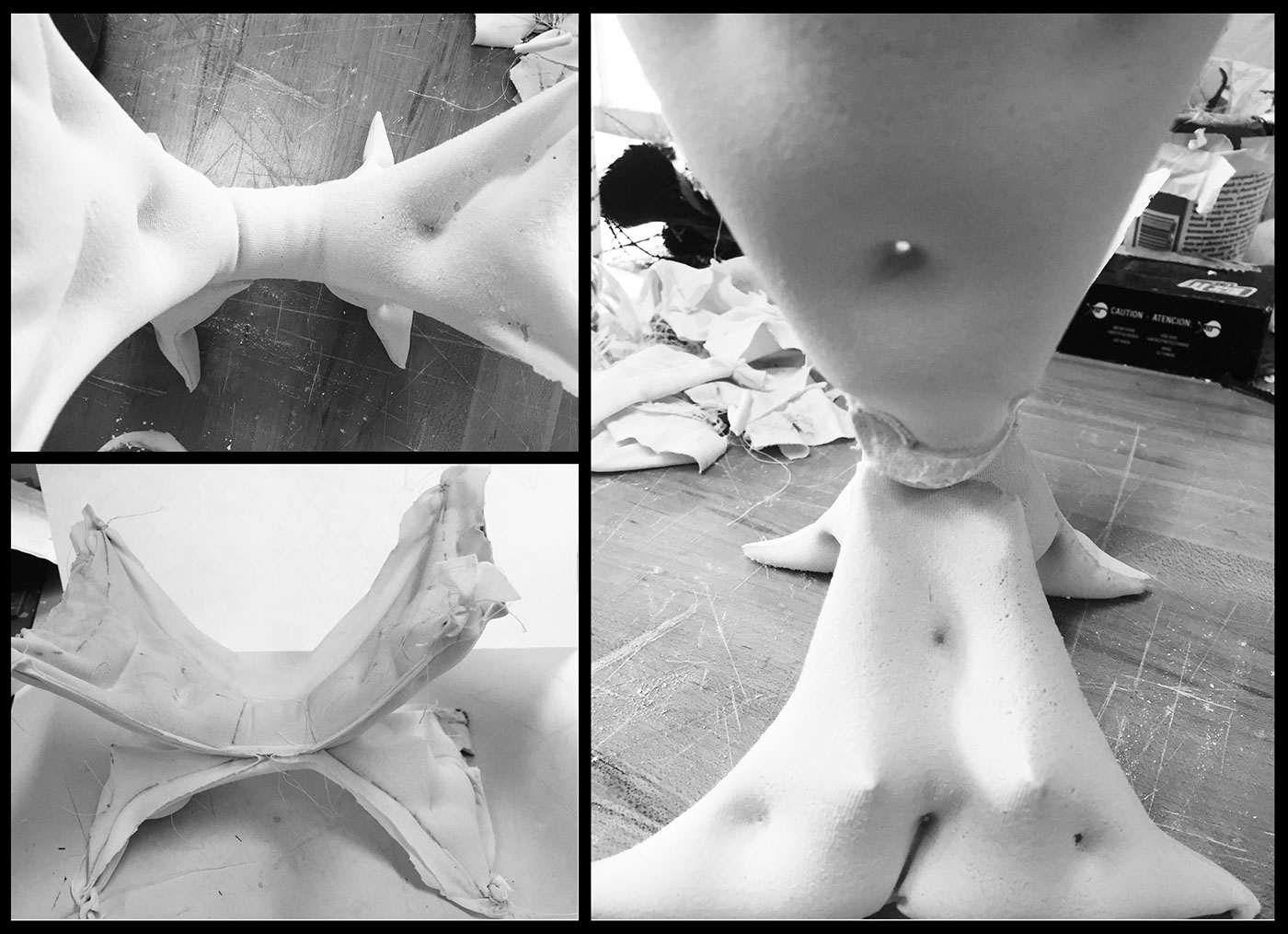

Sewing points together and tensioning them apart in a frame, this object along with the arches below became the frame work for the initial project before the manifestation of the Biergarten

Another test of pulling apart by adding wooden dowels inside the fabric and casting, while pulling it down with a weight. This create a double curved starshaped module.

Part II: The Chair

In order to get introduced to concrete, we began with an initial project of casting a chair. The chair, modeled first in plaster, ended up being about 250 pounds and included the experimental methods of pulling together (to lessen material and weight) and apart (to create phalanges wide enough to support itself). From the chair, we implemented what we learned towards the final project.

Plaster cast chair

Diagraming the template for the cast along with the idealized chair, measured deformation of the concrete pour, and movement of the clamping washers

Framework

Final chair collage, documenting all modes of failure including port failure, settling failure, cinching failure, foot failures, edge failures, bulge failures, warp failures, setting failures, corner failure, seam failure, and dimensioning failures - all of which are both errors and realizations that helped in the final project.

Part III: Site and Bier(Garden)

The site we chose sat between two closely situated buildings which included a single trash bin. It is located on South Main Street in Providence, RI.

The proposed project included a modular platform made from precast concrete that could facilitate human activity through a biergarten, connecting the wine shoppe across the street and adjacent restaurants.

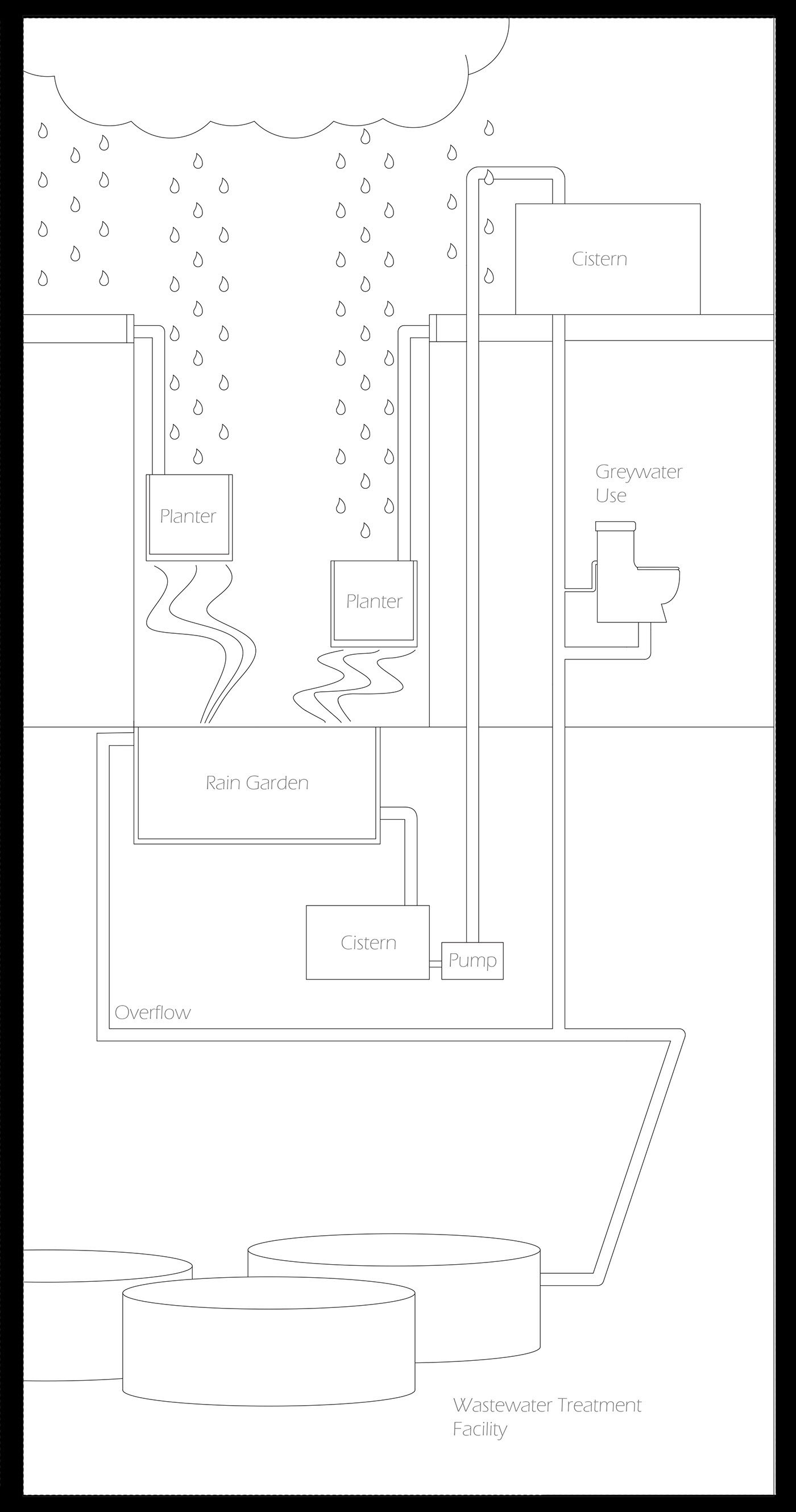

The garden component comes from its integral design of a cistern for rainwater collection and reuse. The water would flow to the bottom of the site, which included a raingarden for filtering the water.

At thee end, we casted the main pieces that created the platform, the edge of the gutter/ drainage system, and the planter base and retaining wall.

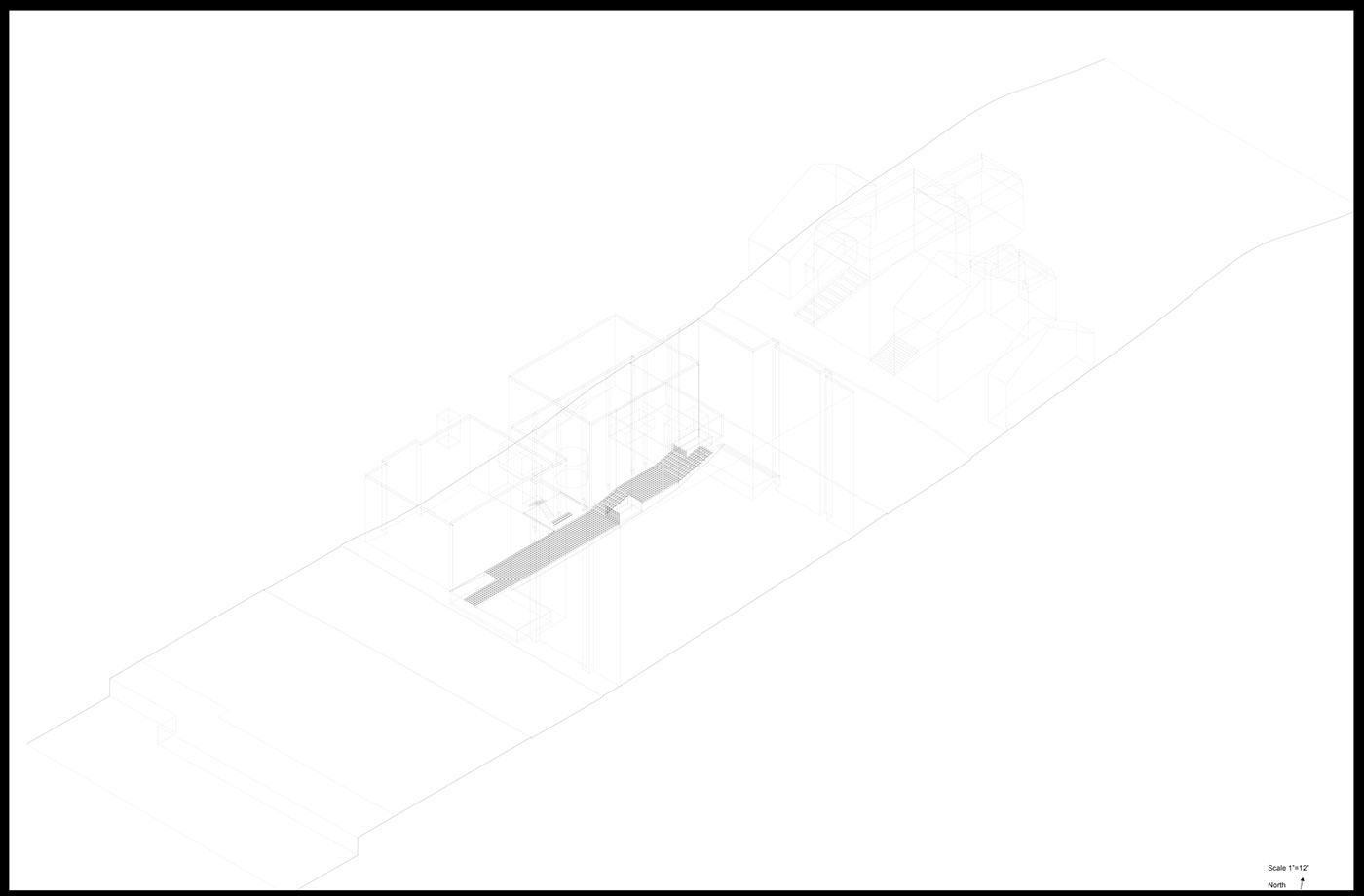

Site axon including modules

Water flow diagram for use and distribution

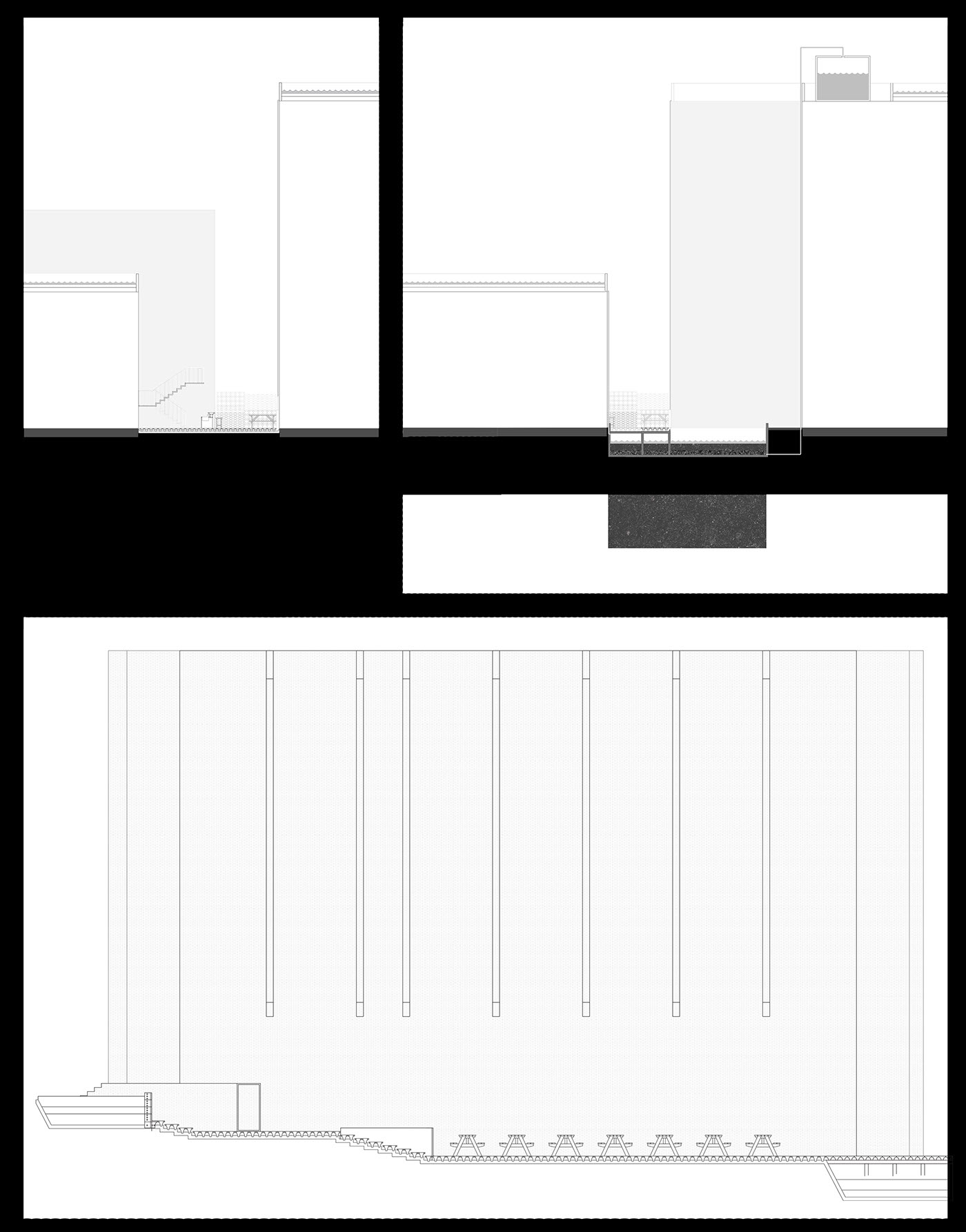

Planter pieces - retaining wall (top) and planter top (bottom)

Construction

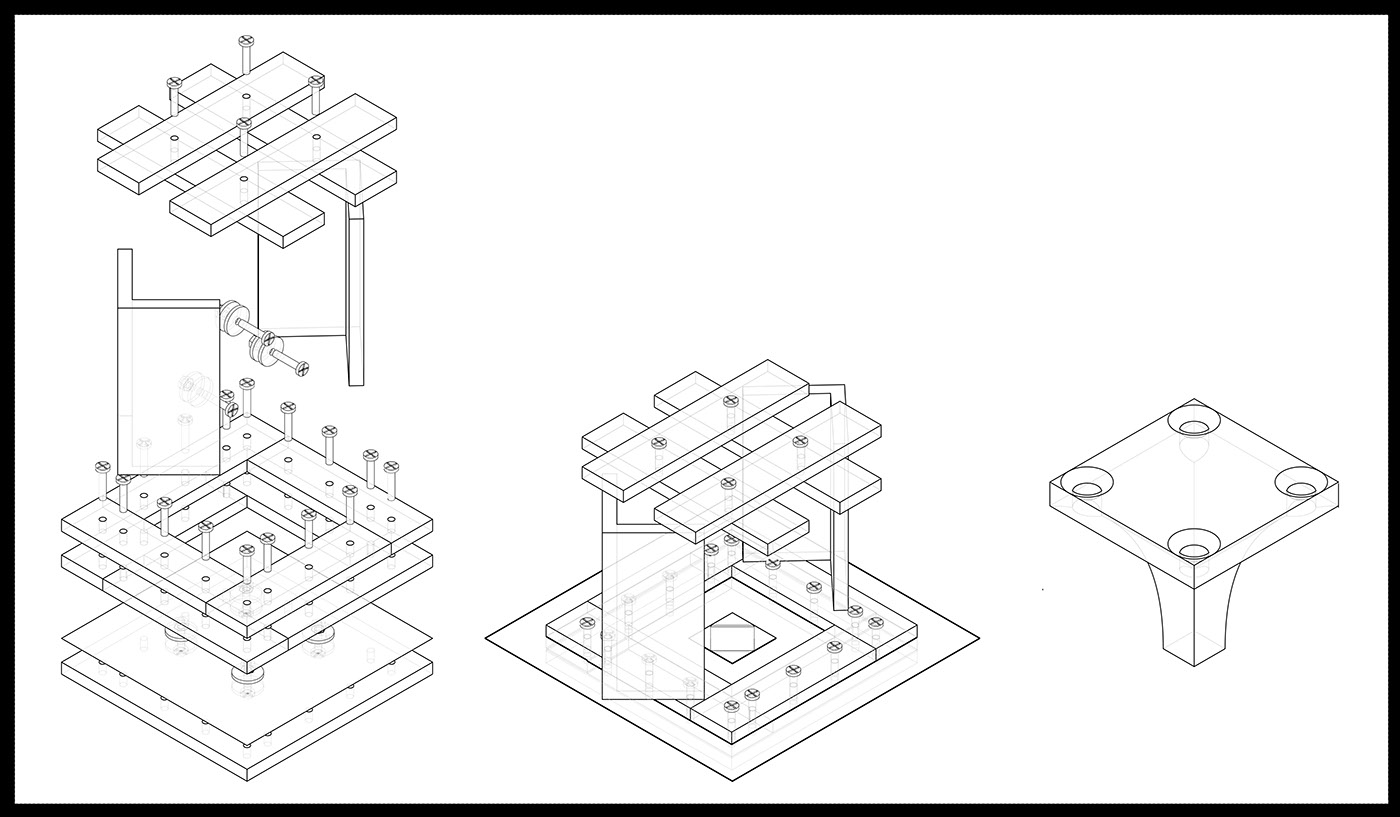

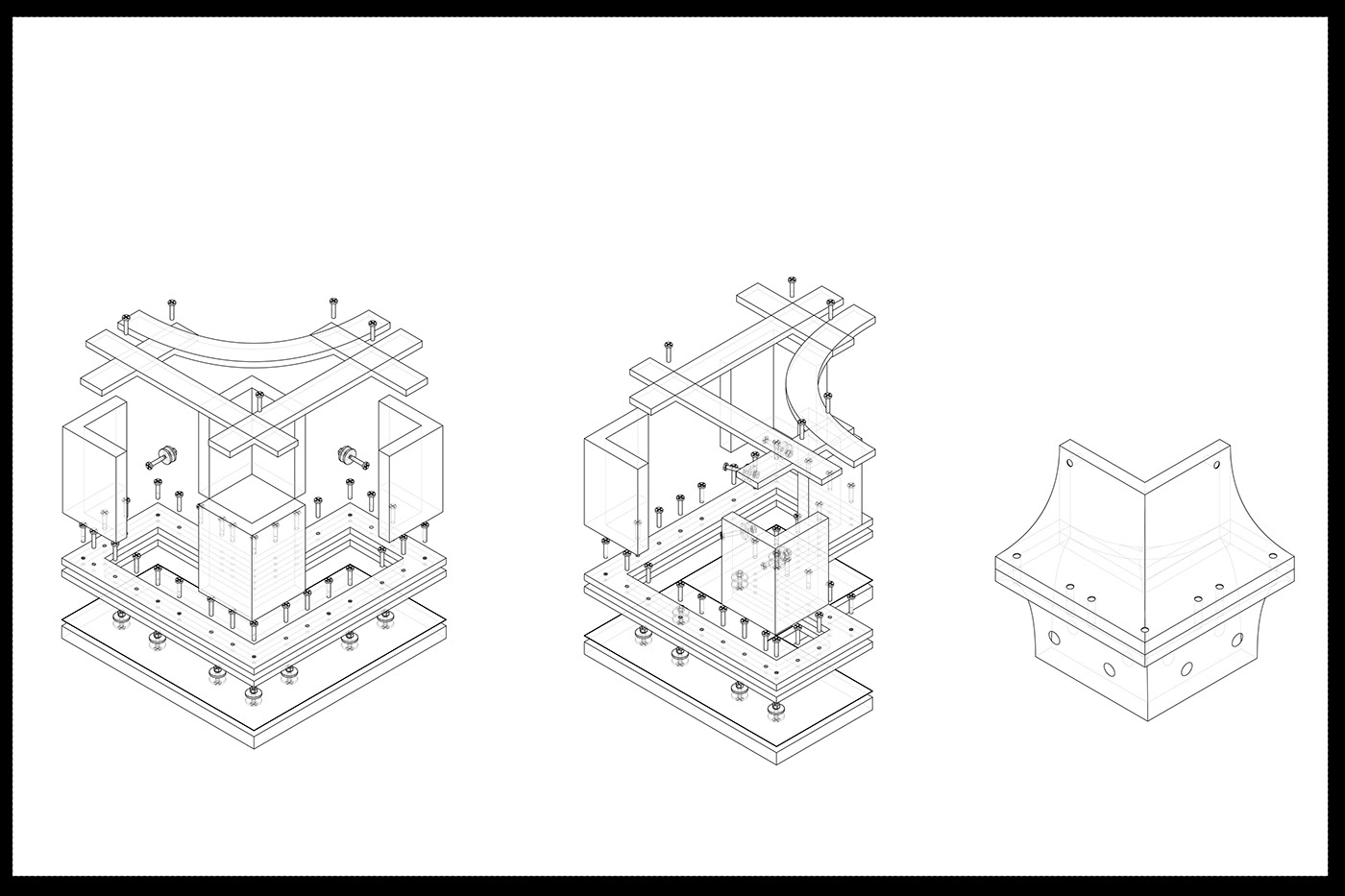

Below are the frameworks used to cast each piece.

Module for floor

Module for corner piece (planter)

(left) floor to planter piece

(center) planter retaining wall piece

(right) curb piece

Diagram of modules by creation, weight, and fabric type used

Image of critique on final day, including planter edge, gutters, modules, and to the far right, some of the fabric swatches are shown.