THE ALUMINUM PROJECT

An object made from the research of the thickness and pliability of aluminum sheet metal. One can twirl the many aluminum elements to see each one interact with the other.

Explorations with the material led me to these small slivers of aluminum, which was sawed along the thickness of the sliver, and pounded down to hold a smaller piece within. This small experiment piqued my interest, and I tested it to see how it would expand.

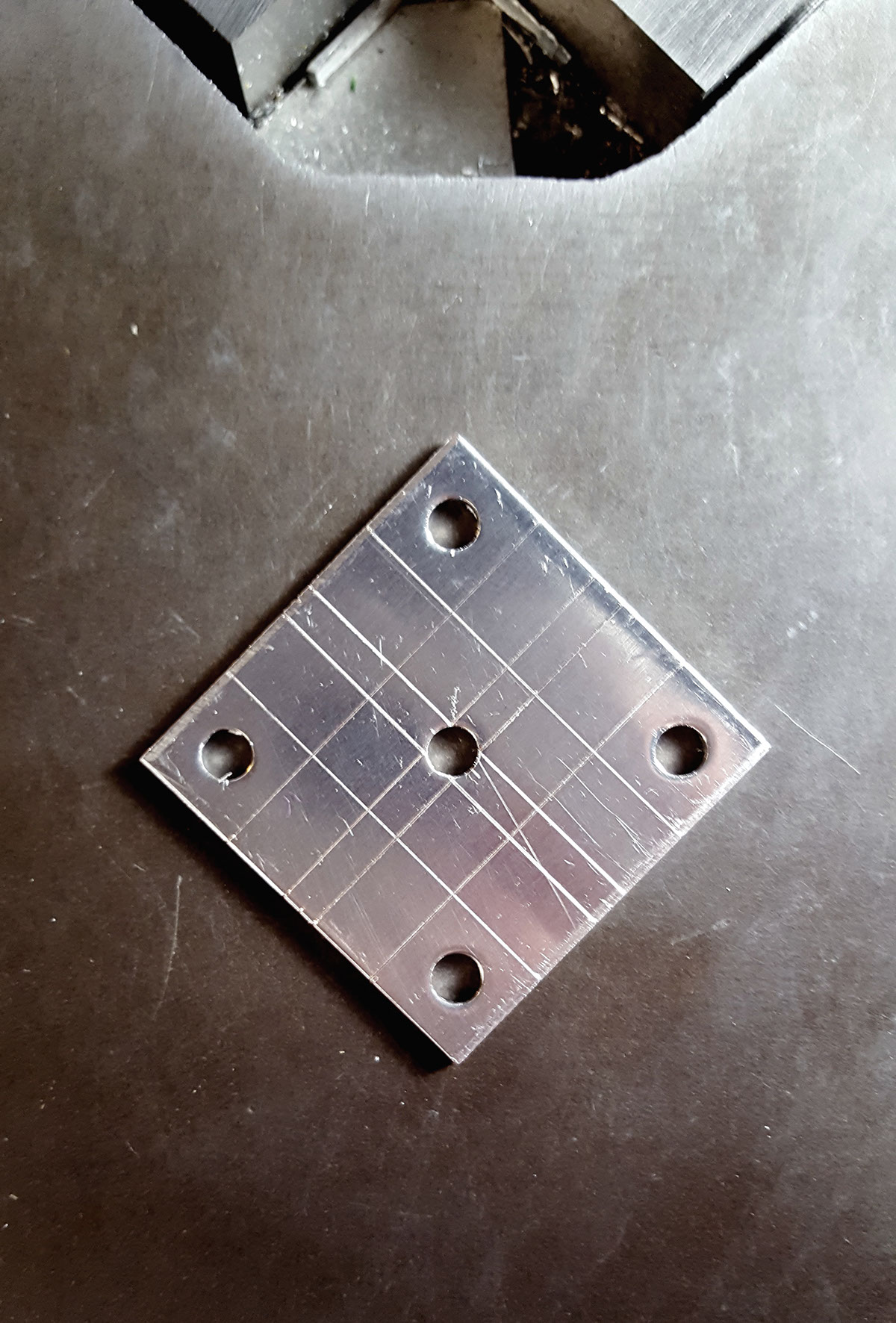

The initial inspiration has been made into a large square with four of the split-end aluminum interactions. The forging had been forgone, to reduce the element of randomness. Two of the identical objects had been placed on an axis to see if there was a pattern that could emerge.

If the smaller squares of metal stuck in the split-ends were rounder, would the objects move around better? Moving on, I also finished the edges of the entire object overall, so there would be no rough angles to cause irritation to the hands.

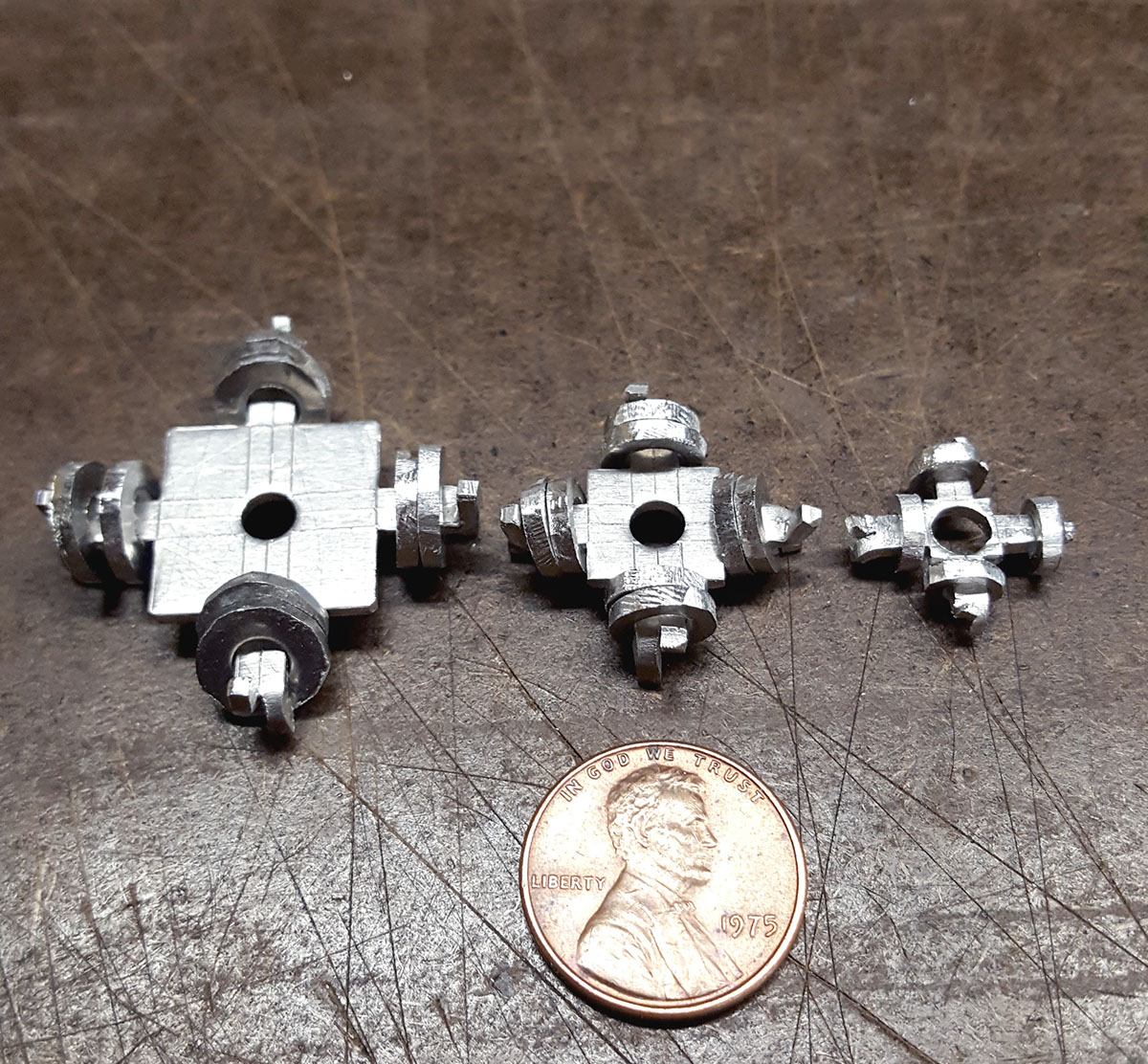

After witnessing the aluminum washers interact with one another, I started to see them all influencing one another on the same axis. What if, there were multiple sizes of these objects, and when one was disturbed, the rest would follow? I then proceeded to scale them down and up to a presentable size.

When creating the objects, I considered it from a manufacturing standpoint. How can I produce the least amount of waste for the most amount of production? The split-end square and its respective washers can be created from a single square, with a pattern laid out on it. The primary tools used to cut it were the corner press, and the jeweler's saw.

Precision was key in producing each object. I tested the limits of the material against the corner press, until the scaling became so that it was not able to go further.

Thank you!~