Metals II, Spring 2016, Instructor: Dean Robinson

Machining

A compilation of metal projects manufactured from stock material.

Prompt #1 | Timeline: 2 Weeks

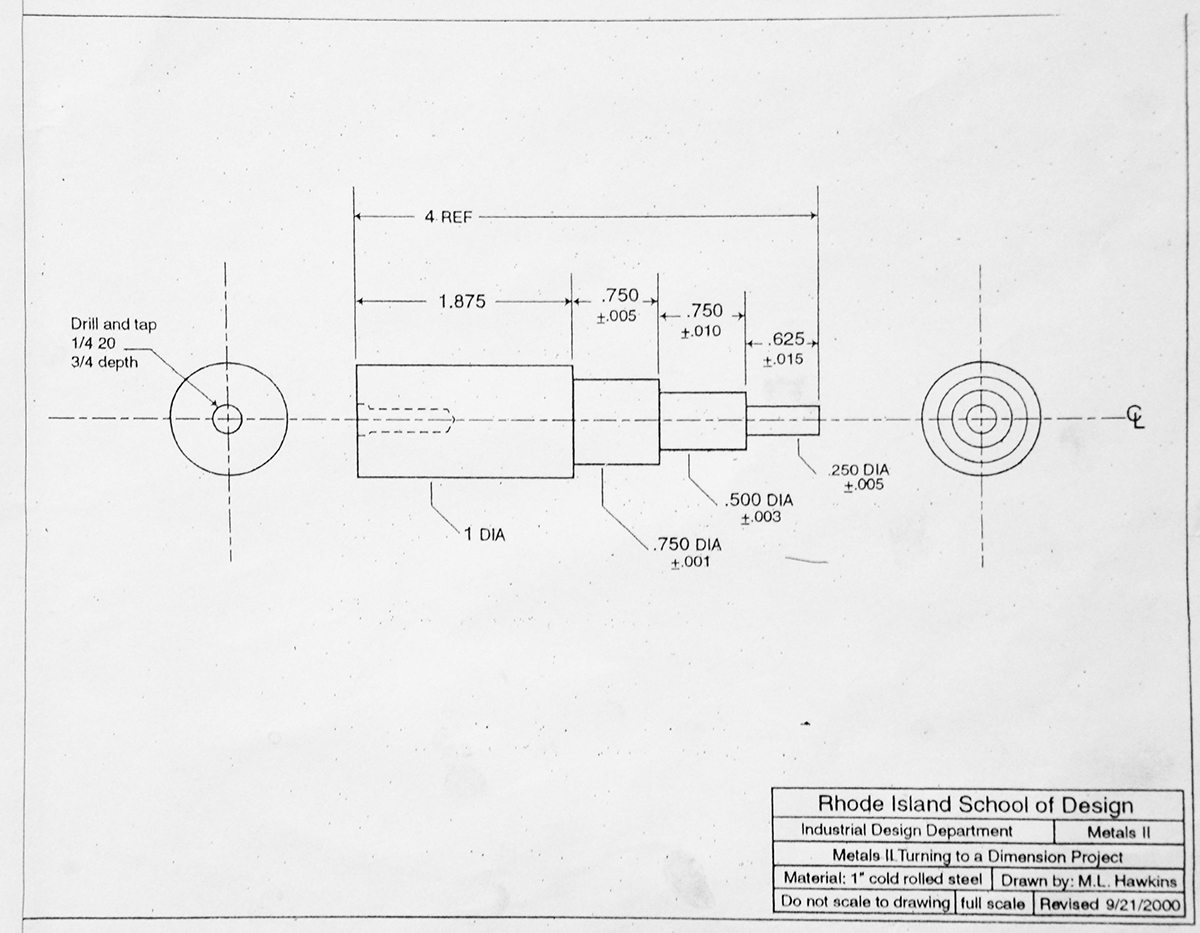

Turn 1" cold-rolled steel to dimension based on the orthographic below within the tolerances listed.

Process

Below is my step pin made within .001" tolerance. The pin was turned on a metal lathe and stops were placed on the ways in order to create precise measurements. I used a four-jaw chuck and finished all edges with a file. All diameter measurements were made with a micrometer.

Prompt #2 | Timeline: 1 Week

Mill a block of maple utilizing the Bridgeport.

Process

Using the digital readout, I created this symmetrical block.

Prompt #3 | Timeline: 2 Weeks

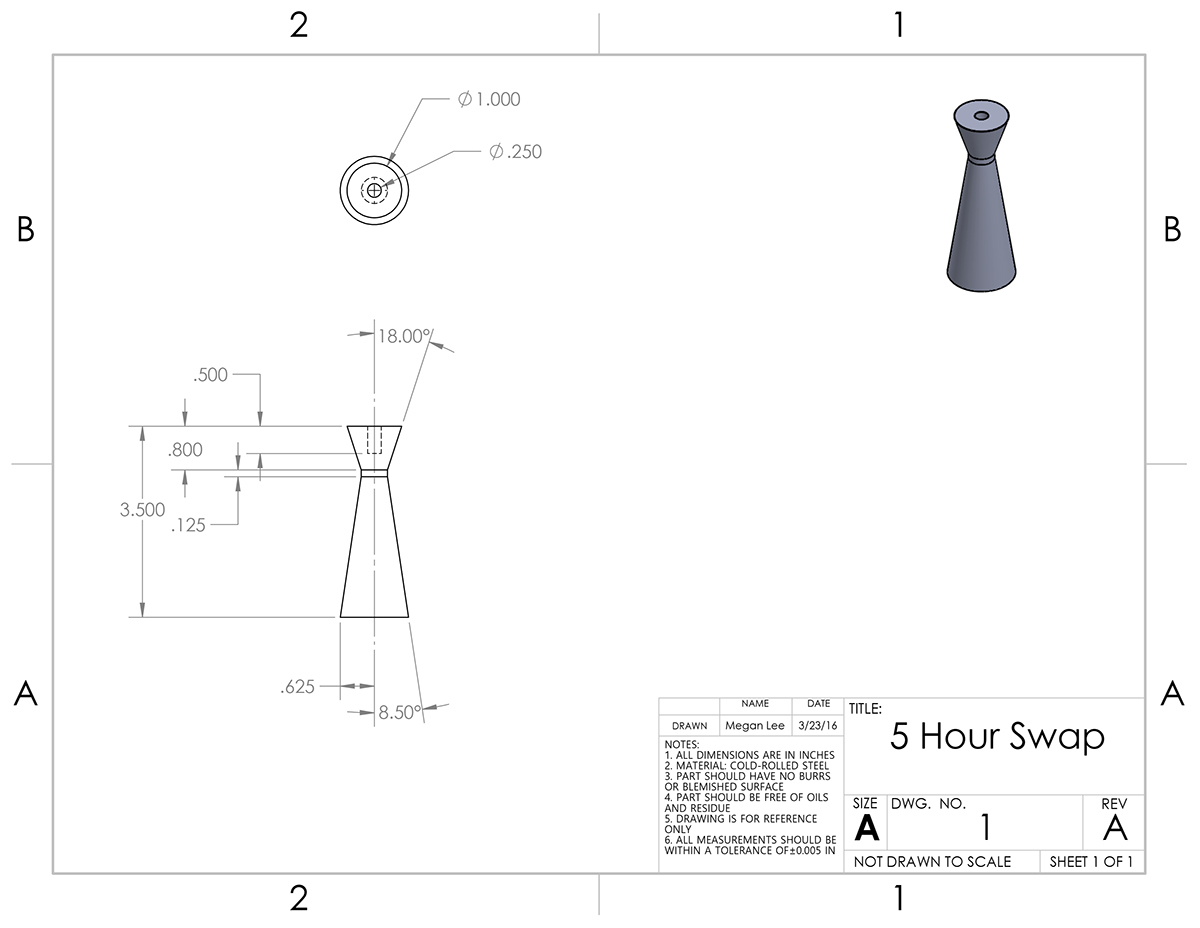

Design an object that can be manufactured within 5 hours out of round stock less than 2" in diameter and less than 4" tall.

Process

I created the below drawing, and it was manufactured by my classmate Jerry Ding.

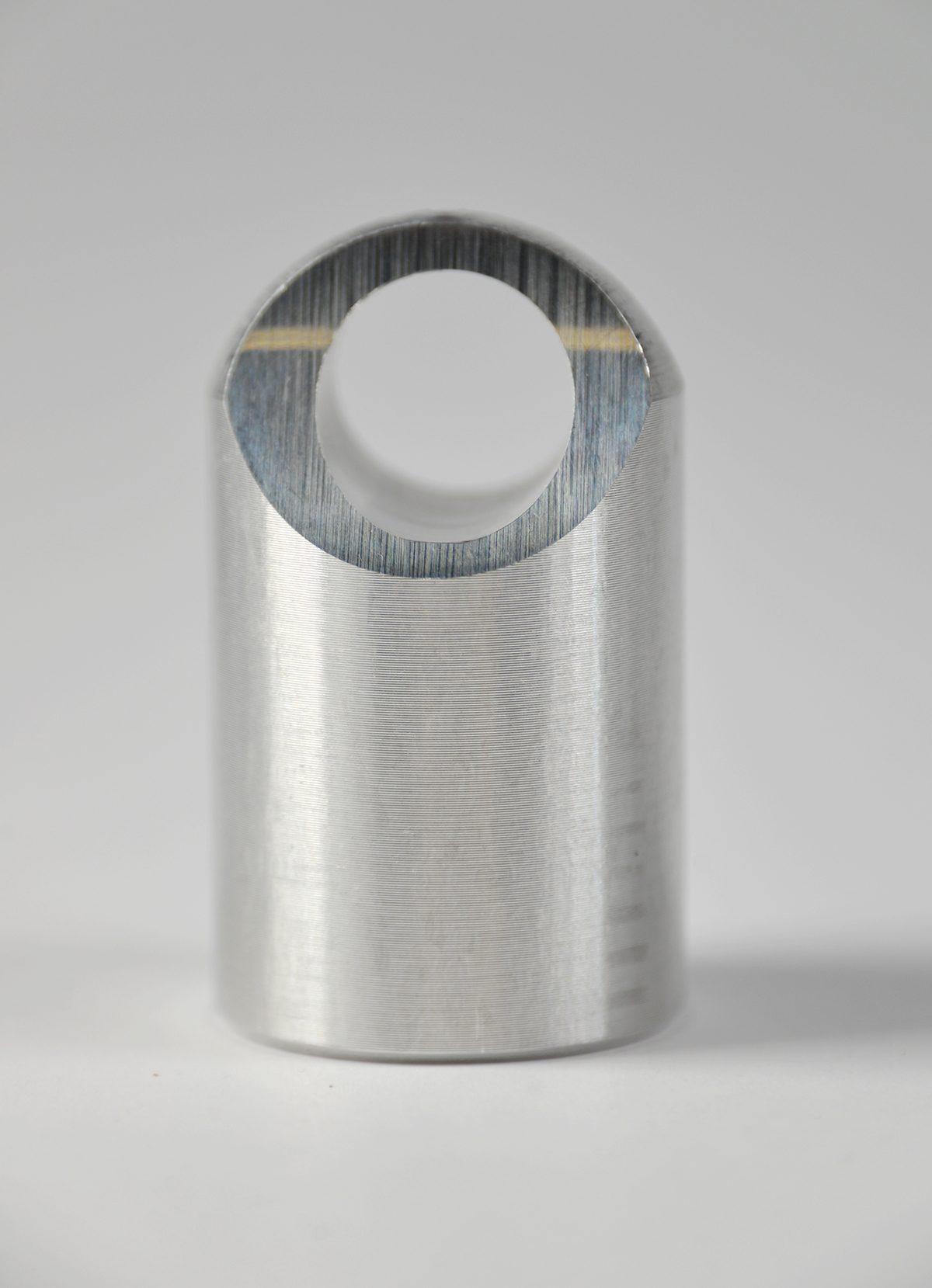

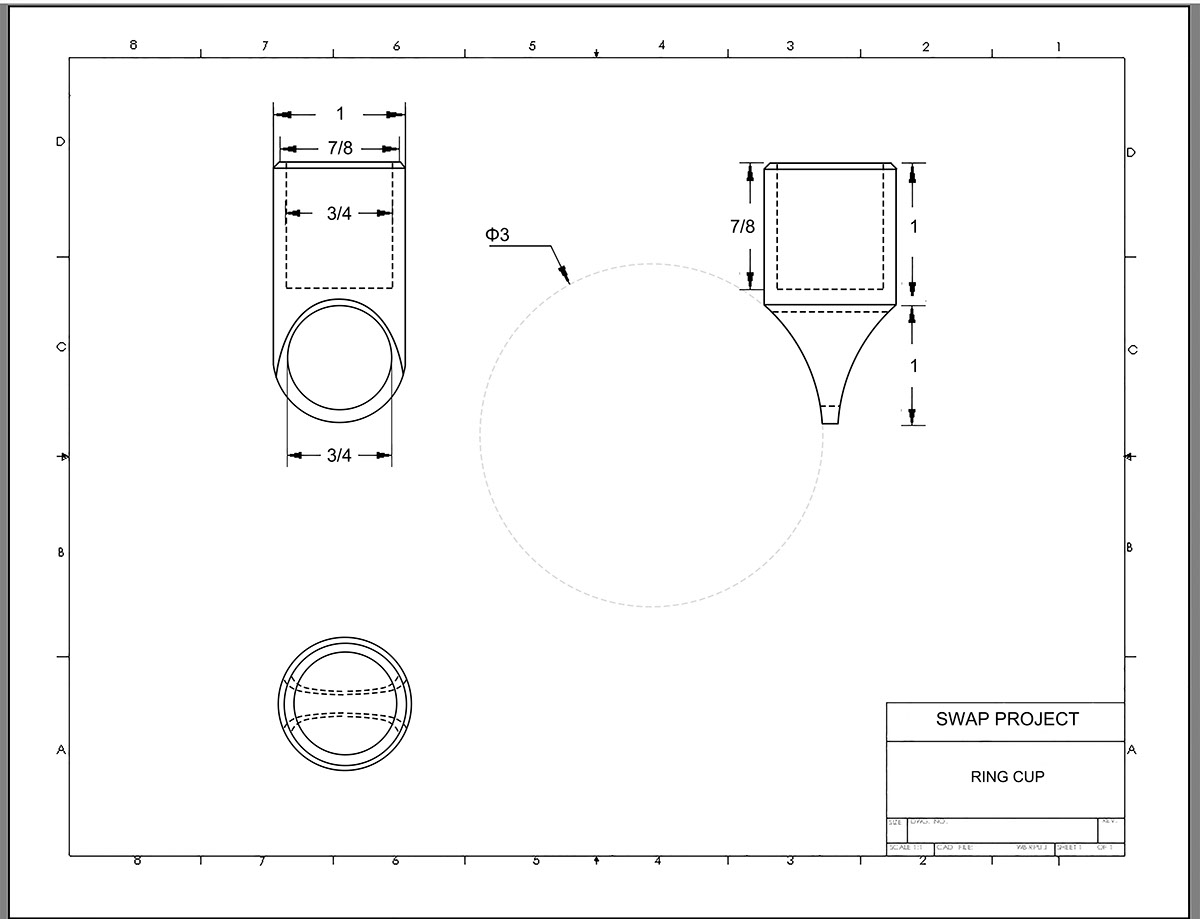

Below is the object I was asked to manufacture. The drawing was generated by classmate Creama Wong. Many of the measurements were re-dimensioned due to the limitations of the machinery.

To create the piece, I initially turned the aluminum stock to dimension, then bore the hole in the top of the piece. I then used the radius cutter to create the rounded bottom. Next, I set up the Bridgeport to allow me to flycut the 3" diameter circle out of both sides. I was able to make symmetrical cuts by using a rotary head. Next, I used an endmill to create the 0.75" hole.