Independent Project, Winter 2015

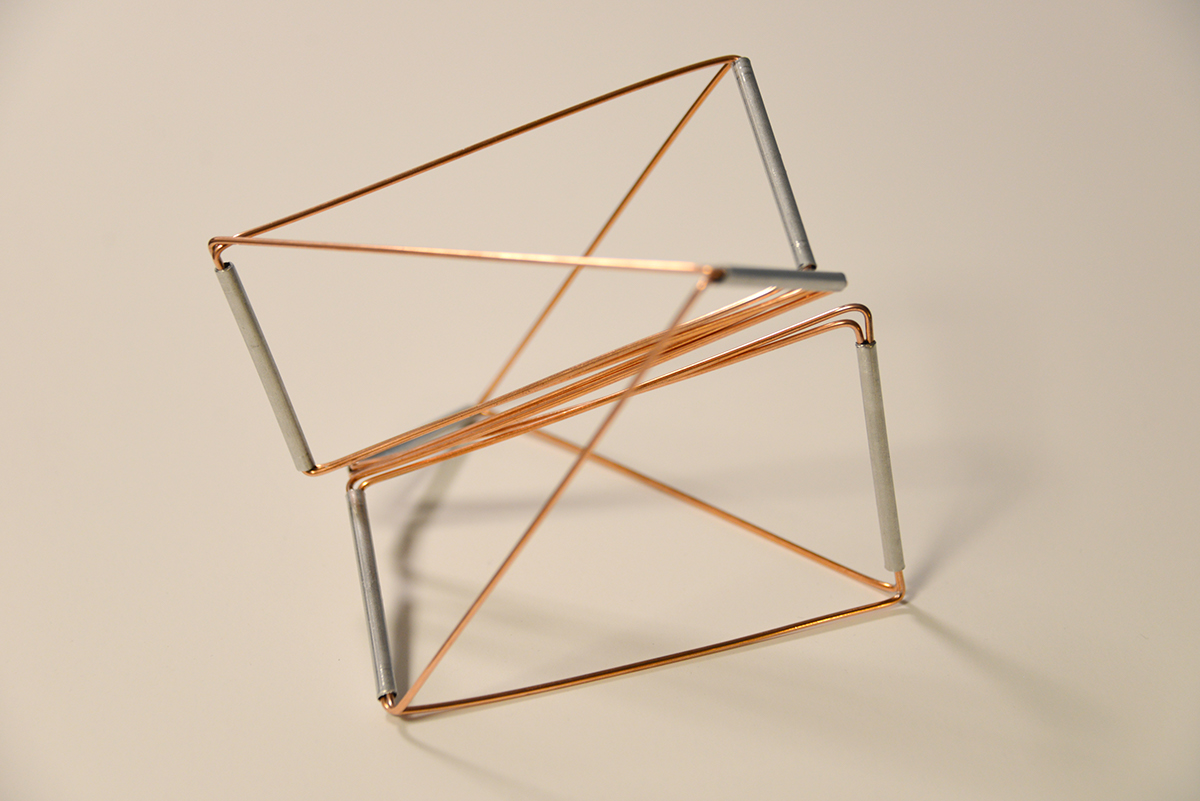

Jitterbug

A study based on a pre-existing toy concept.

After a 30-minute visit to the Loeb Gallery at RISD, I discovered a jitterbug and was interested in making one myself. However, I did not know what materials were used to make the model, nor how it was made (the model had to remain in its completed form).

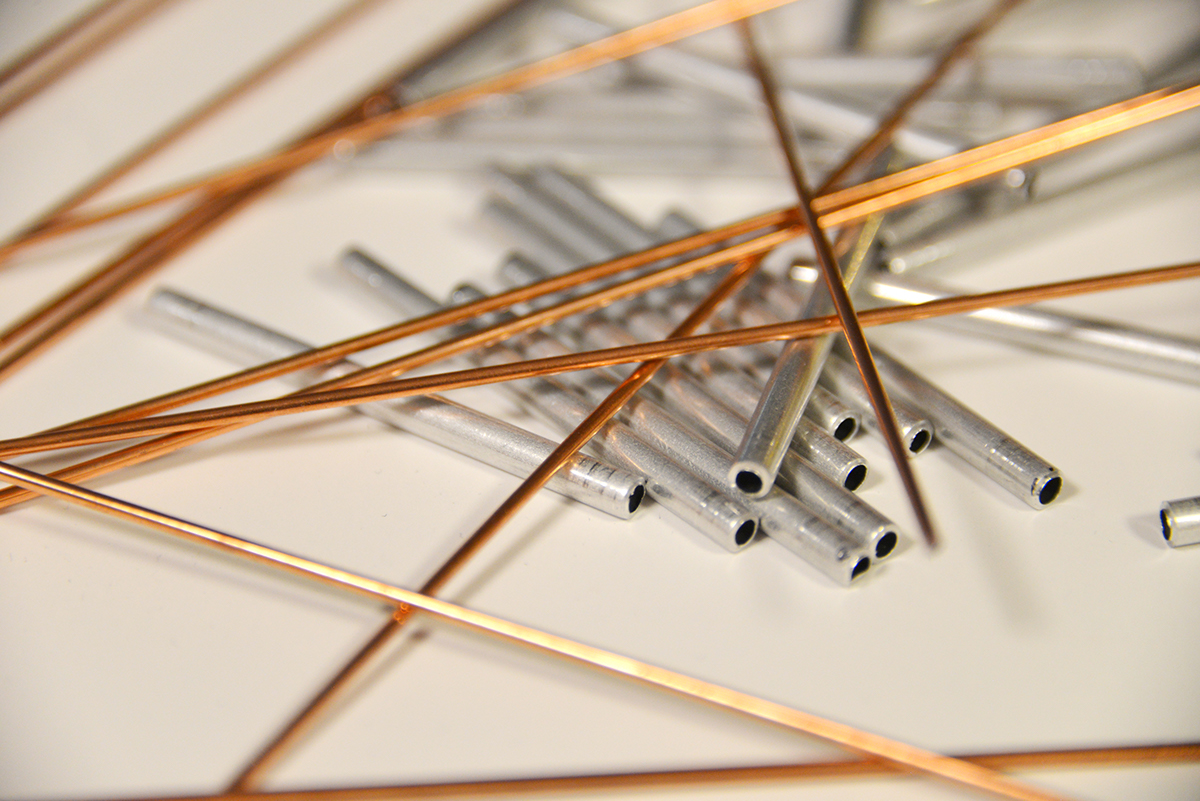

I originally decided to experiment with aluminum tubing and aluminum wire rods, as aluminum is an easily-manipulated material. I later switched to copper-coated steel wire, which retained its form superior to the aluminum wire.

I chose 5/32 tubing and 1/16" gauge wire as the components of this model. This was so that two 1/16" wires could rotate freely in the tube. None of the components of the model could be fixed.

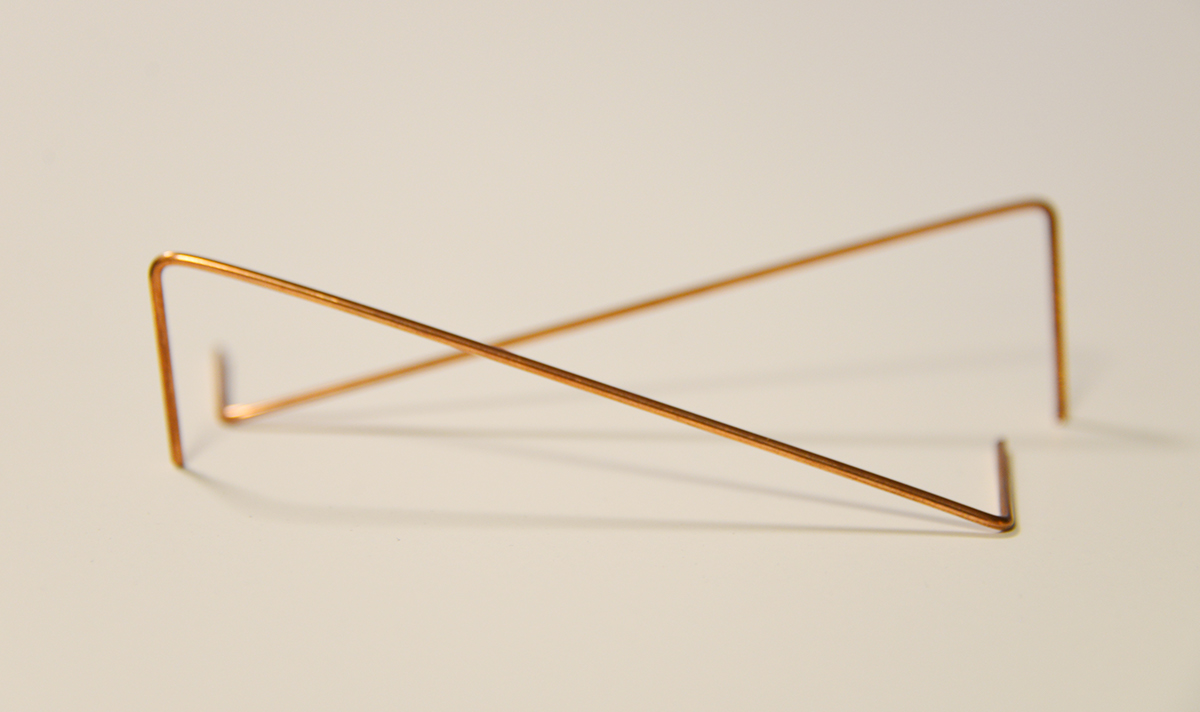

I then experimented with various modules, and discovered the basic form below. This form consisted of two bends in the standardized wire component – a 90 degree bend on an x-plane and one on a z-plane. 6 modules needed to be bent this way. 6 other modules had to bend on the y-plane and on the z-plane.

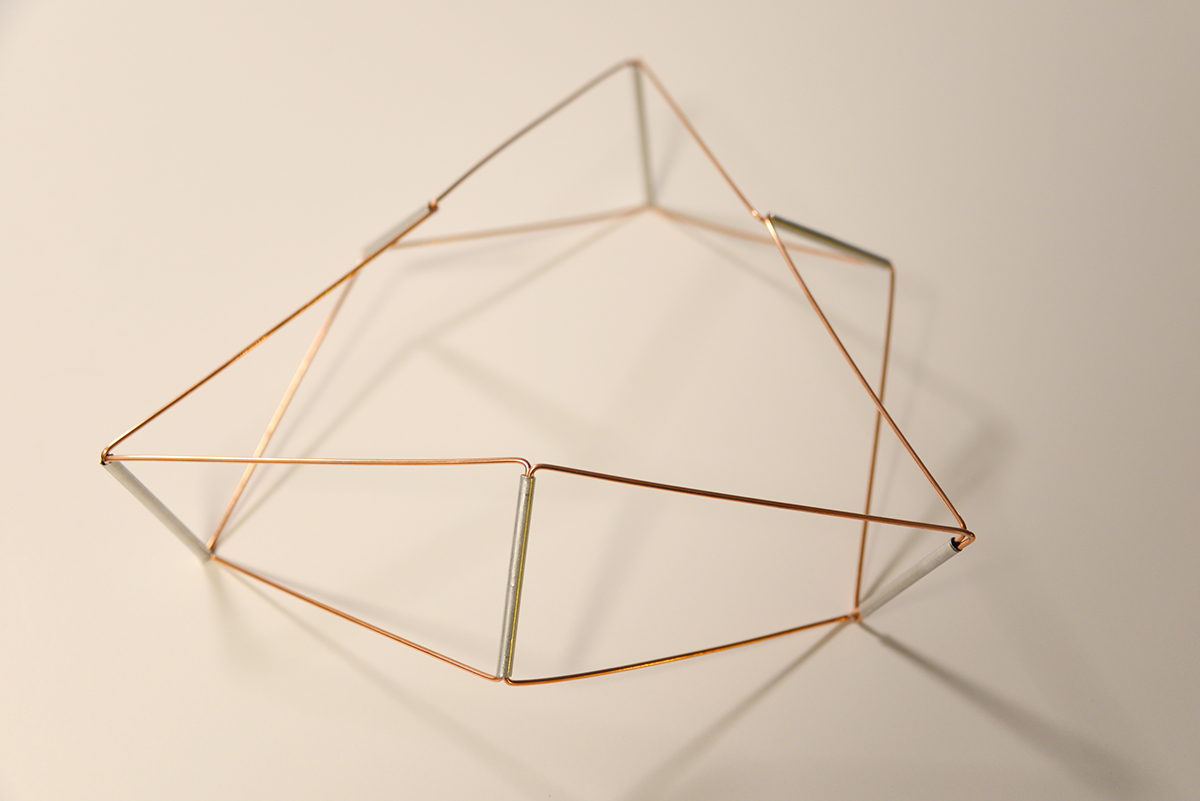

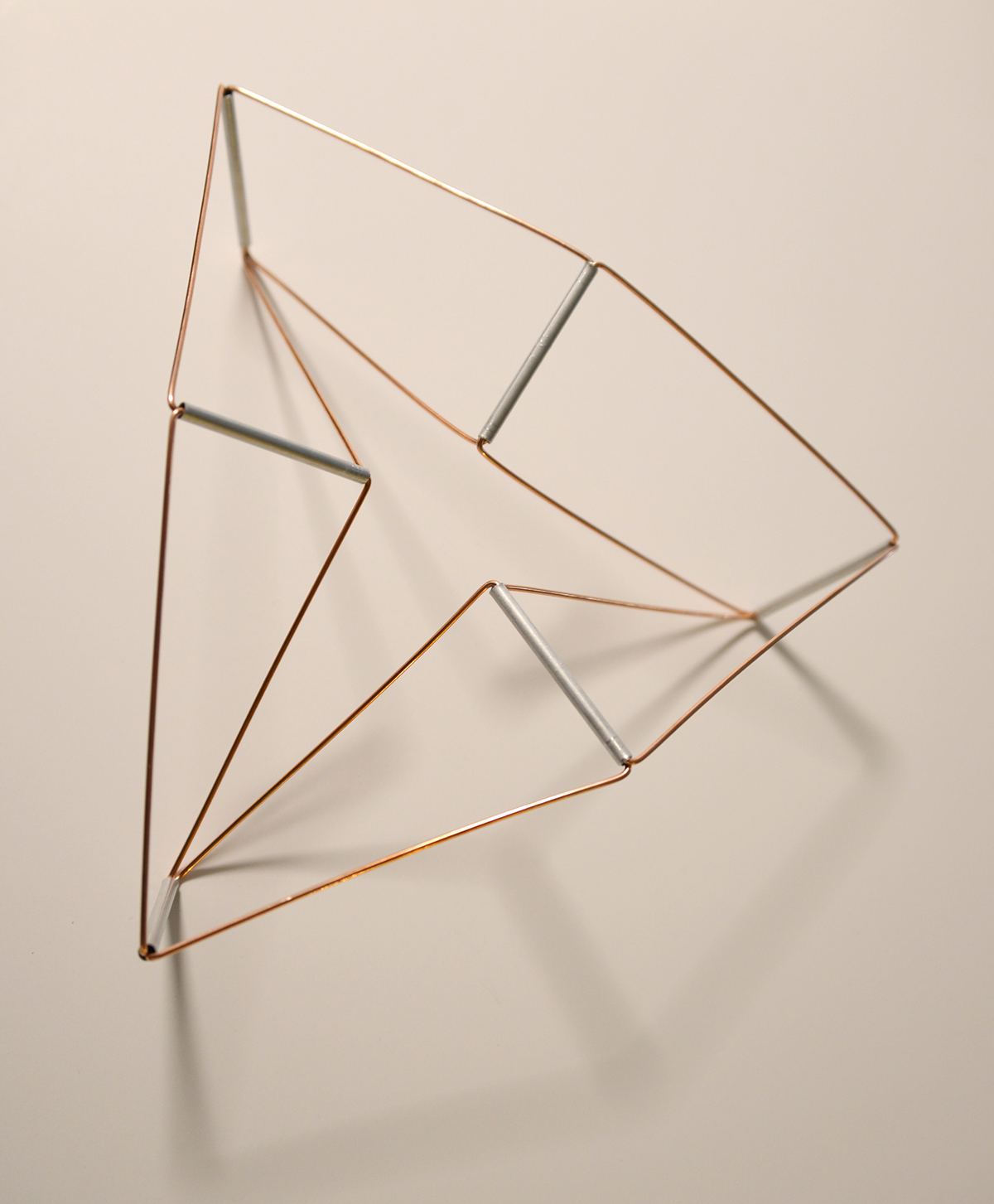

By alternating the modules in pairs and connecting the ends of the wire with a piece of aluminum tubing, I was able to create the final jitterbug. Therefore, the piece is connected solely by its components and no additional adhesives.

In its final state, the jitterbug is able to cycle continuously. It can take on various forms.