Fiber and dyeing studies for Richard Killeaney's first semester textiles course.

Loom-spun Yarn Samples

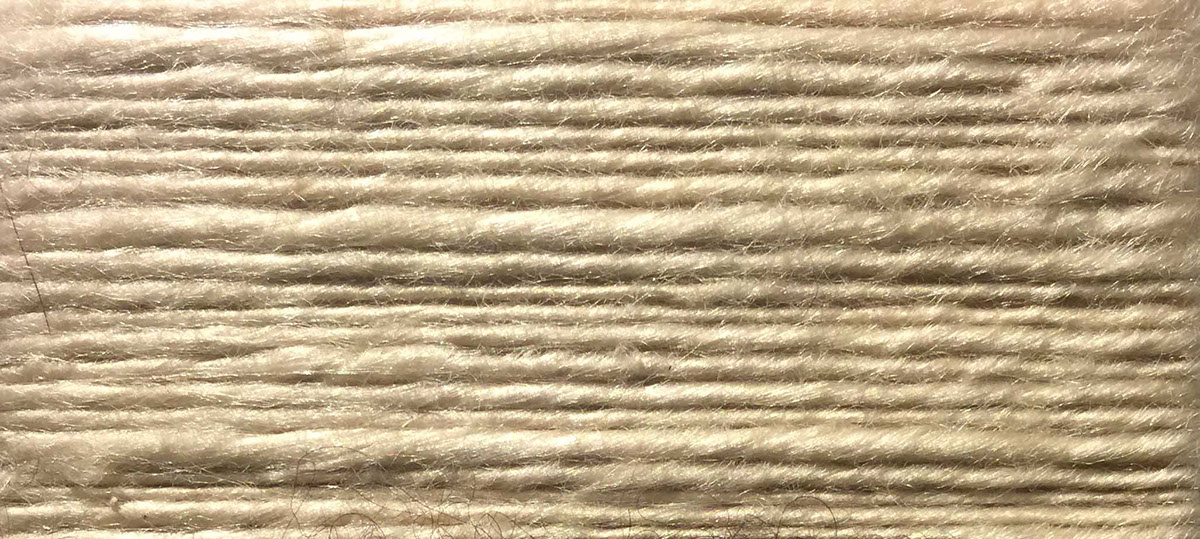

1. Seacell

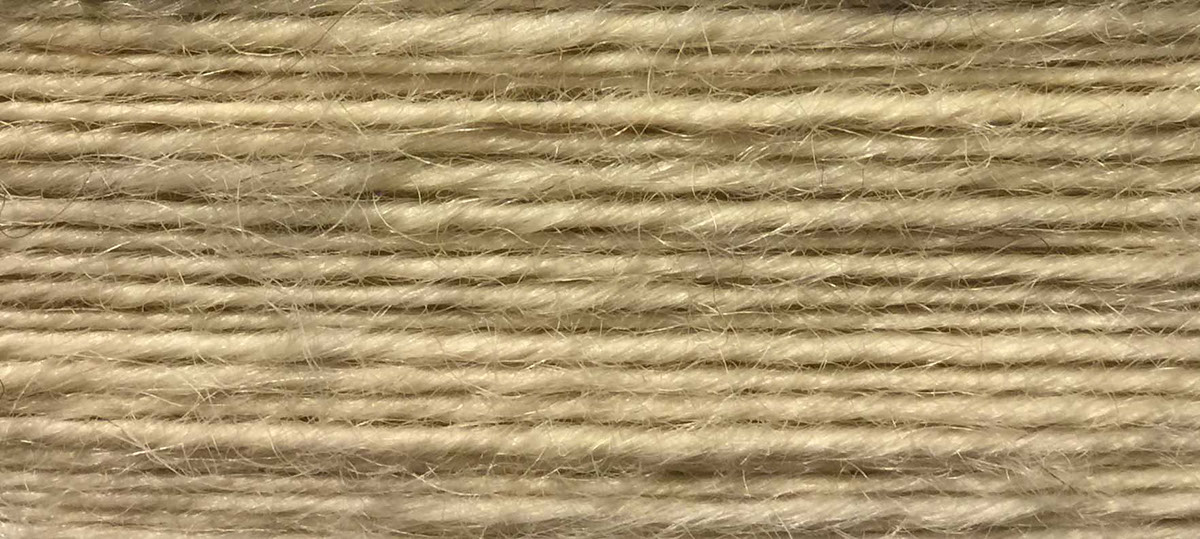

2. Yak

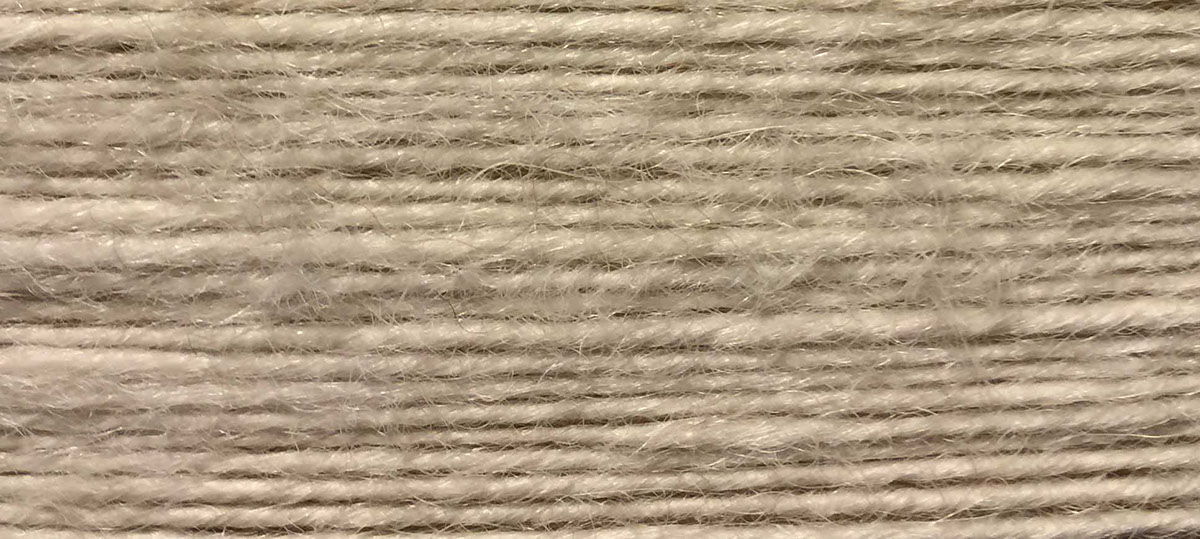

3. Baby Alpaca

4. Lyocell

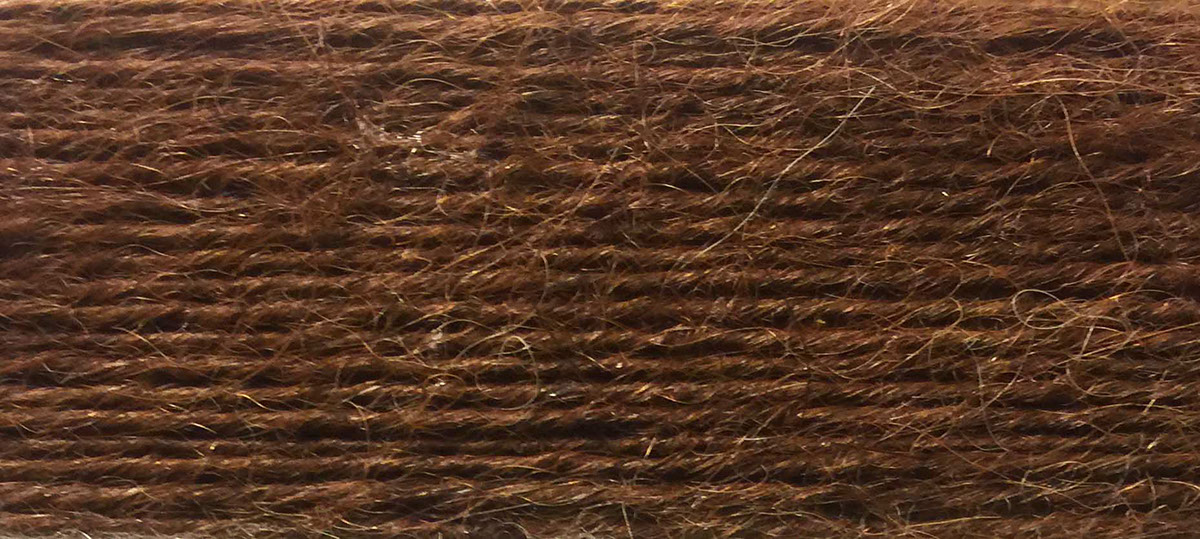

5. Tussah Silk Noil

6. Tesswater Wool

7. Llama

8. Merino Wool

9. Merino-Flax blend

10. Cotton

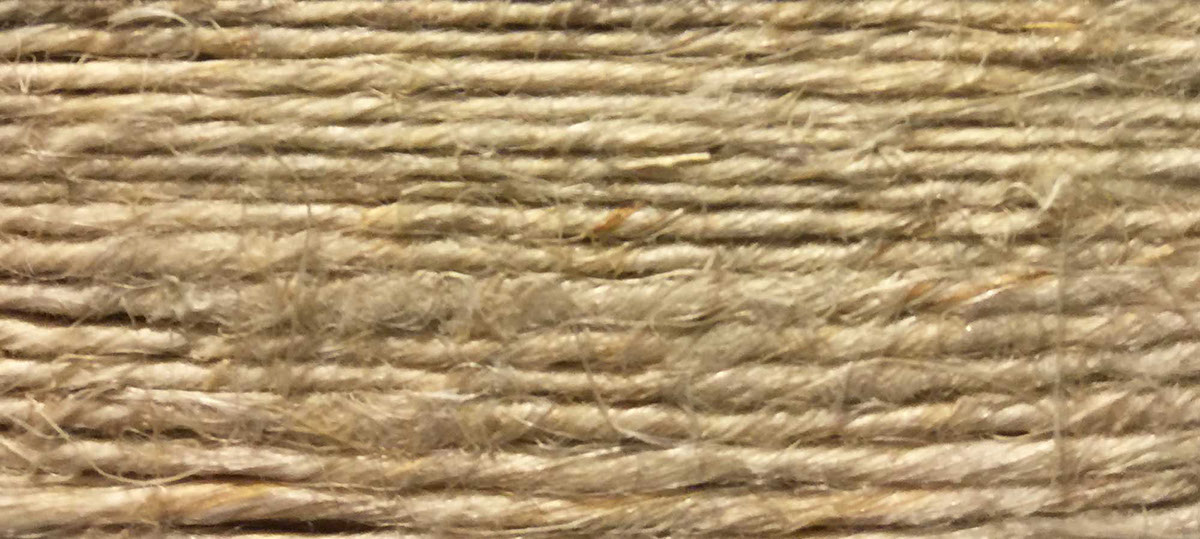

11. Flax

12. Hemp

Seacell: A marine plant cellulose fiber manufactured using a process similar to lyocell. Although perhaps not as plasticky, this fiber closely resembled lyocell, had a good staple length, and was not too slippery.

Yak: A smooth and lustrous fiber produced by a large ox found in Tibet and Central Asia and collected by combing out the spring molt. In short, Yak is the worst; the short staple length made the fiber a horror to spin, although the color is gorgeous.

Baby Alpaca: Noted for its softness, fineness, luster, and long staple length, alpaca fiber is produced by domesticated animals of the South American branch of the camel family.

Lyocell: A lustrous, manufactured fiber composed of solvent-spun cellulose. Spinning lyocell was challenging because it had the tendency to slip off the starting thread, and if spun too thin the fibers would slide apart.

Tussah Silk Noil: Refers to staple silk produced from broken filaments and inner portions of cocoons or waste silk from cocoons in which the caterpillars matured into moths. Silk Noil was a beautiful chestnut color and a joy to spin; it had the softness of silk but was also a little grimy, so it was less challenging getting the fibers to “stick” to one another.

Tesswater Wool: A large-diameter, long-stapled, high-luster fiber produced by Tesswater sheep from Teesdale, England. While spinning, this wool behaved a lot like Merino—fairly easy to handle and able to get thin—though maybe a little less soft.

Llama: A fiber produced by the South African llama noted for its softness, fineness, and luster. Llama was somehow a thousand times hairier than all the other hair fibers—even when I finished spinning and mounted my sample, hairs were spewing out of the yarn at every turn.

Merino: Superior quality wool produced by the Merino sheep. Although it may just be because we’ve been working with Merino for a while now, I found it fun to spin because I could easily get a thin, even fiber, not to mention it has such a nice hand.

Merino-Flax Blend: a mix of superior quality merino wool and flax, a fiber extracted from the flax plant. Spinning this was somewhat of a disaster, because flax is so straight in contrast to merino, which is more like a piece of puff.

Cotton: A soft, fluffy staple fiber that grows in a boll, or protective case, around the seeds of cotton plants. Above, I said spinning Yak was the worst—I take it back—because cotton, with its incredibly short staple, was just as bad, which makes them both the worst. Sorry, Yak.

Flax: A soft, lustrous, and flexible fiber extracted from the bast beneath the surface of the stem of the flax plant. I felt like Rumplestiltskin trying to spin straw—flax pre-water was rough on the hands.

Hemp: A bast fiber similar to flax with high strength, resiliency, and luster. Another Rumplestiltskin moment; I loved the color of this fiber and it felt even slightly rougher than flax.

MX Dye Gradient

Magenta to orange on white muslin fabric.

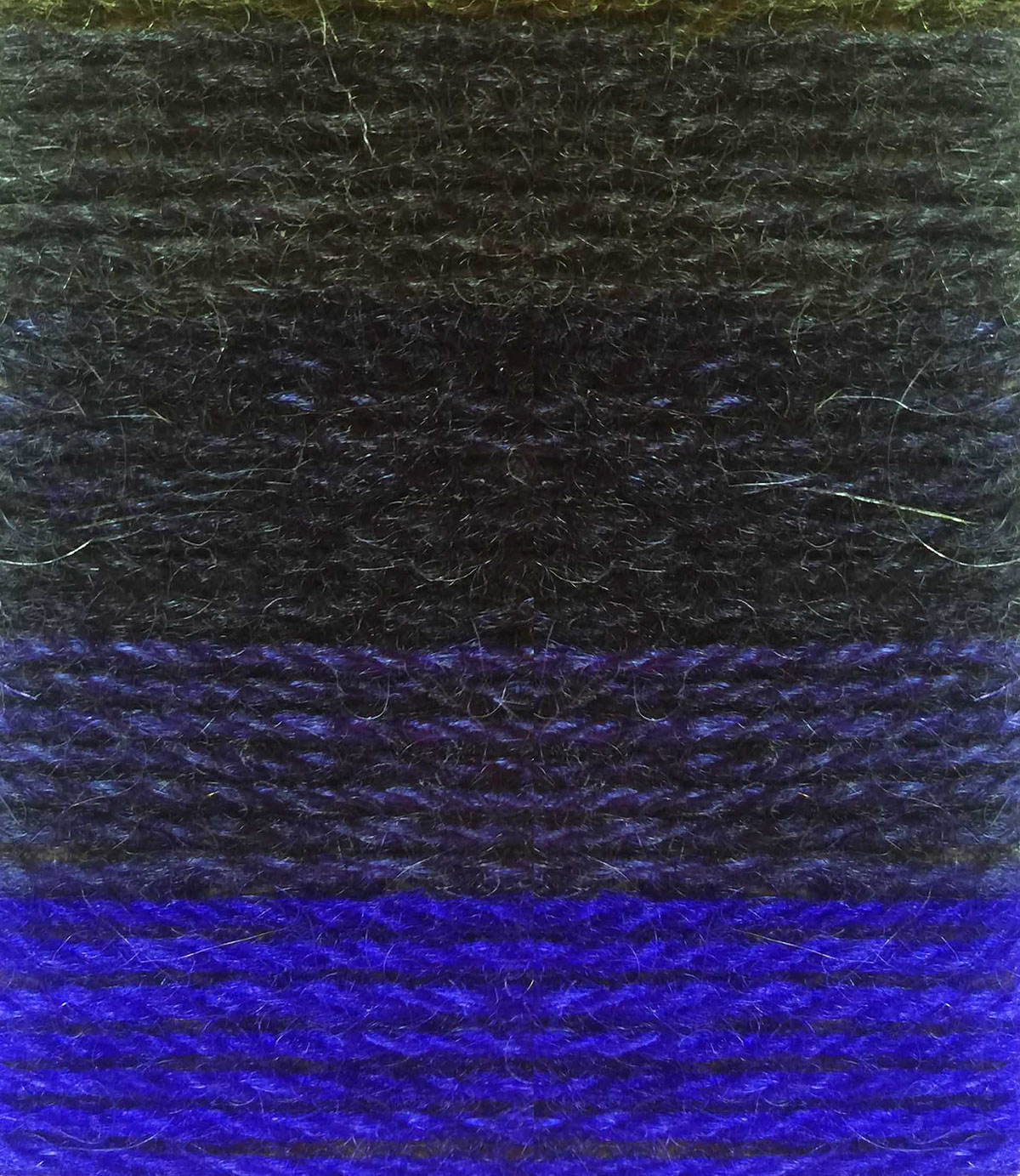

Acid Dye Gradient

Yellow to violet on wool yarn.

Acid Dye Color Wheel

Dyed on gray (outer ring) and white (inner ring) wool yarn.

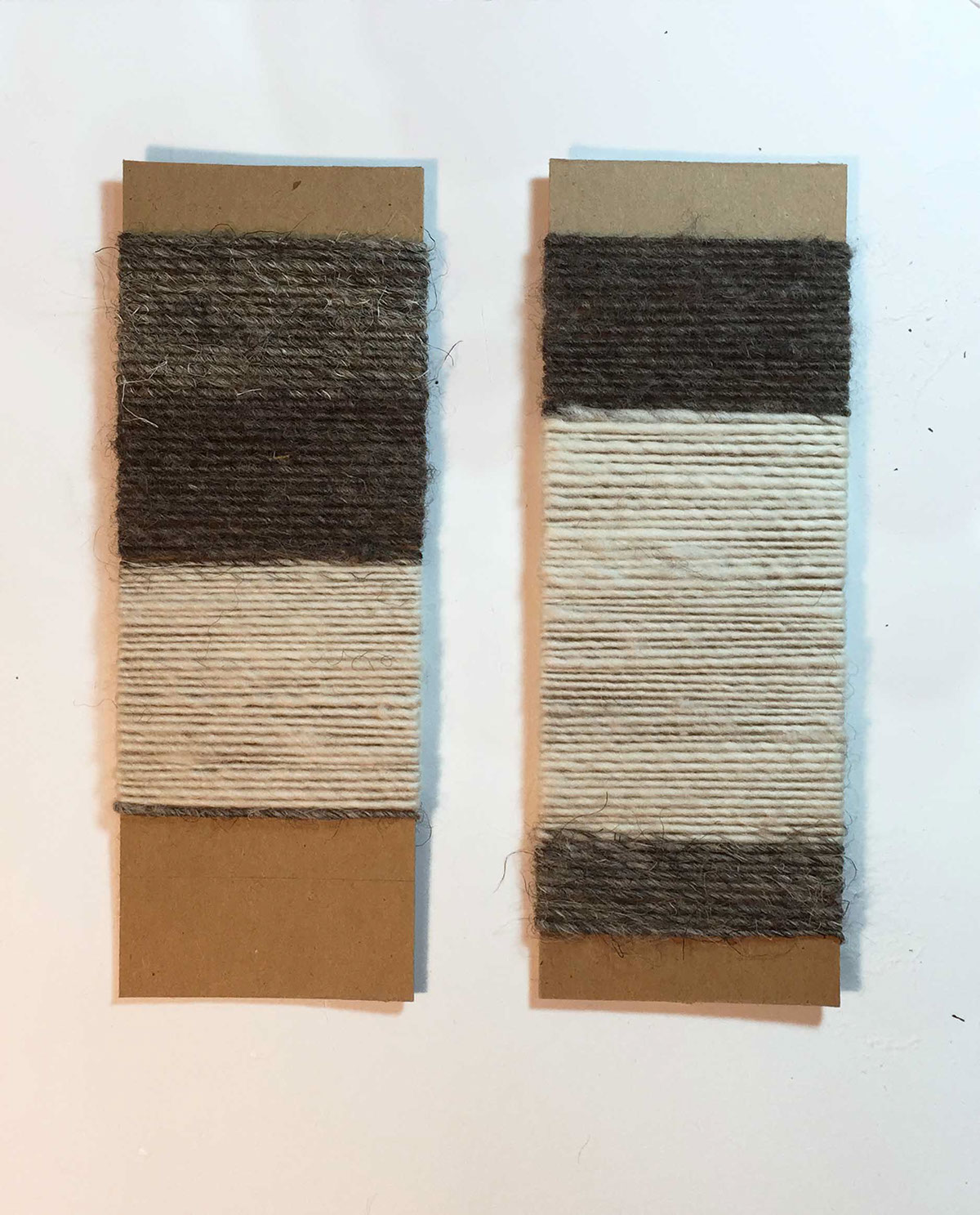

Drop-spun Wool Yarn Samples

My goal in spinning this yarn was to master the making of a moderately thin, consistent thread with all three variations of wool. When first introduced to the drop spindle in class, I couldn’t seem to get away from a ghastly, thick-thin pattern which looked like an accident because frankly, it was. I was approaching things in a step-by-step manner which definitely held me back; I would pinch the yarn, spin more twist into the thread, pinch a few inches above, and let go. I neglected to work the large tuft of wool and pull as I twisted in a more continuous motion. Once I felt familiar enough to tug on the tuft of wool as the drop spindle spun, my yarn became consistent and I felt the motions come naturally. My favorite parts of what I made are the white wool sections. Although this variety was perhaps the most difficult to handle, it wasn’t scratchy and made a tight yarn sans flyaways. In the future I would like to experiment with an artistic integration of the wool, such as an ombre or grey/white/grey/white, as well as varying widths of yarn. After seeing some of my classmates work I am also determined to make an even thinner yarn! When mounting my yarn I also noticed that I still have room for improvement in my transition between wool. The yarn was either a tad too thick or too thin around these areas. Overall I find the drop-spindle to be an important tactile experience that instilled in me the basic idea behind fibers.

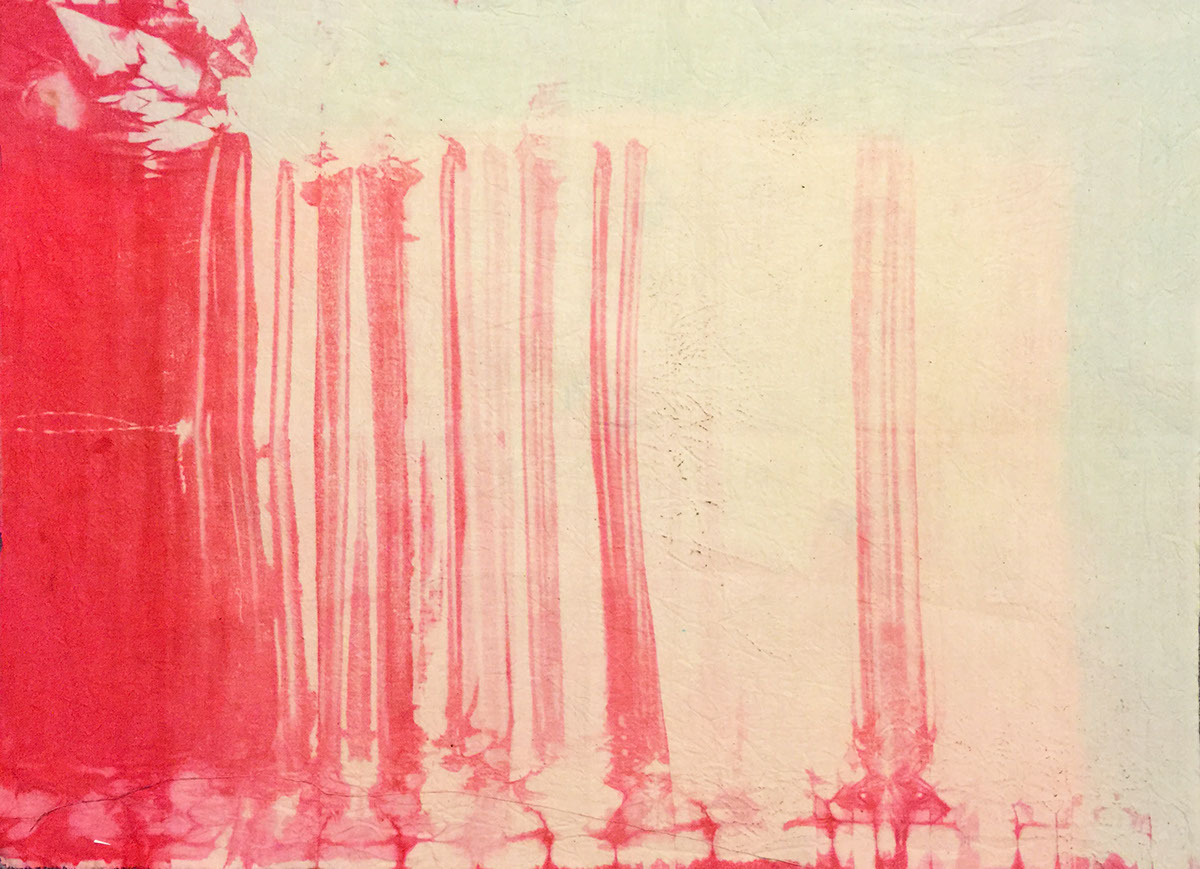

MX Dyeing Techniques

Off-white muslin hand-dyed with MX Pro Fuschia and MX Pro Turquoise using BBQ skewers.

Off-white muslin hand-dyed with Pro MX Fuschia and Pro MX Turquoise using square wooden blocks and rubberbands.

Polyester Heat Transfers

Heat transfer dyeing on solution-dyed white polyester fabric.