All of the following work was produced in Metals One, a Rhode Island School of Design class for Industrial Design sophomores. It focuses on cold connections and basic tooling in sheet metal. The design process shown here is only a tiny fraction of the work as it developed, and is given merely as examples of the study made.

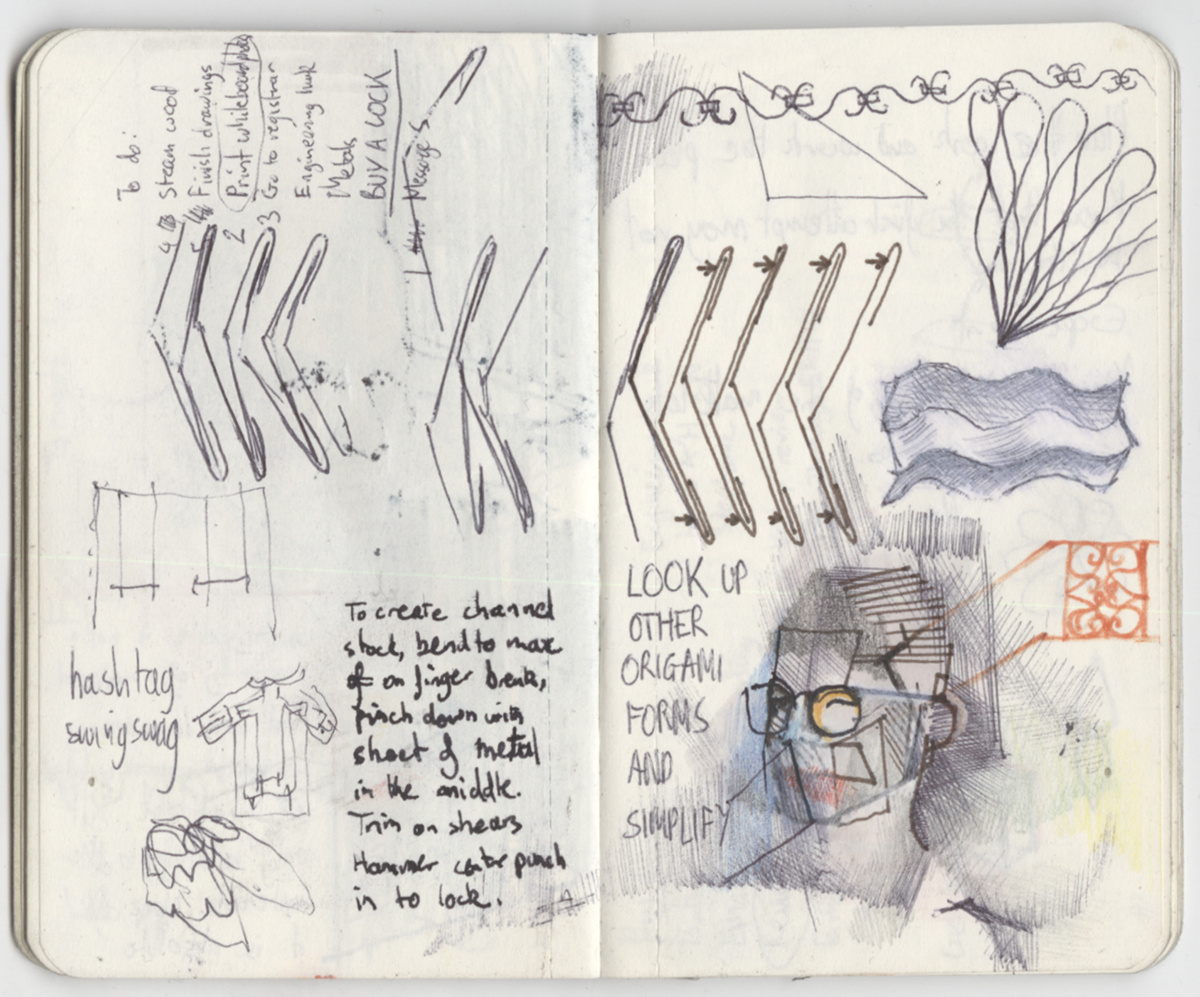

Early material testing

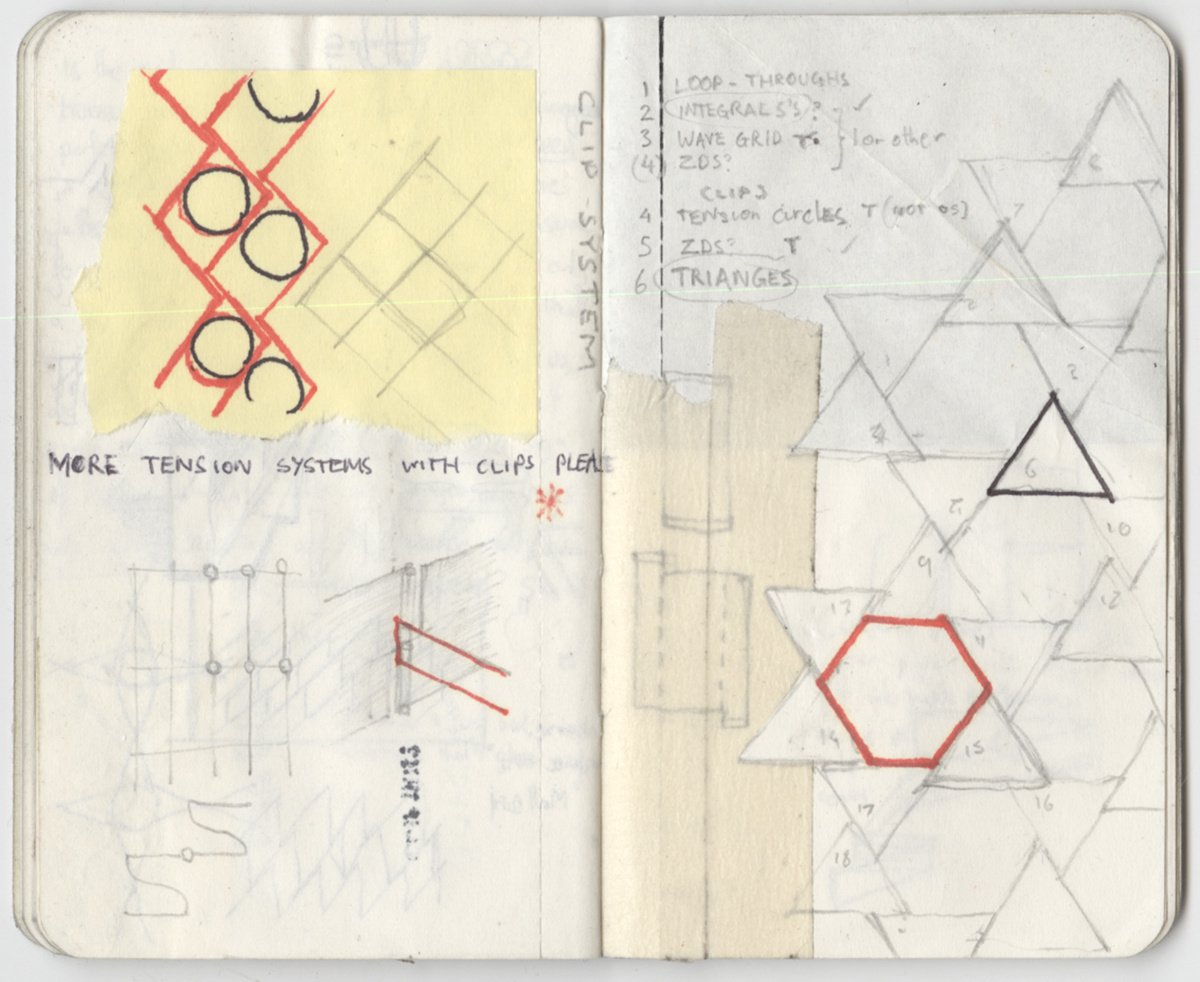

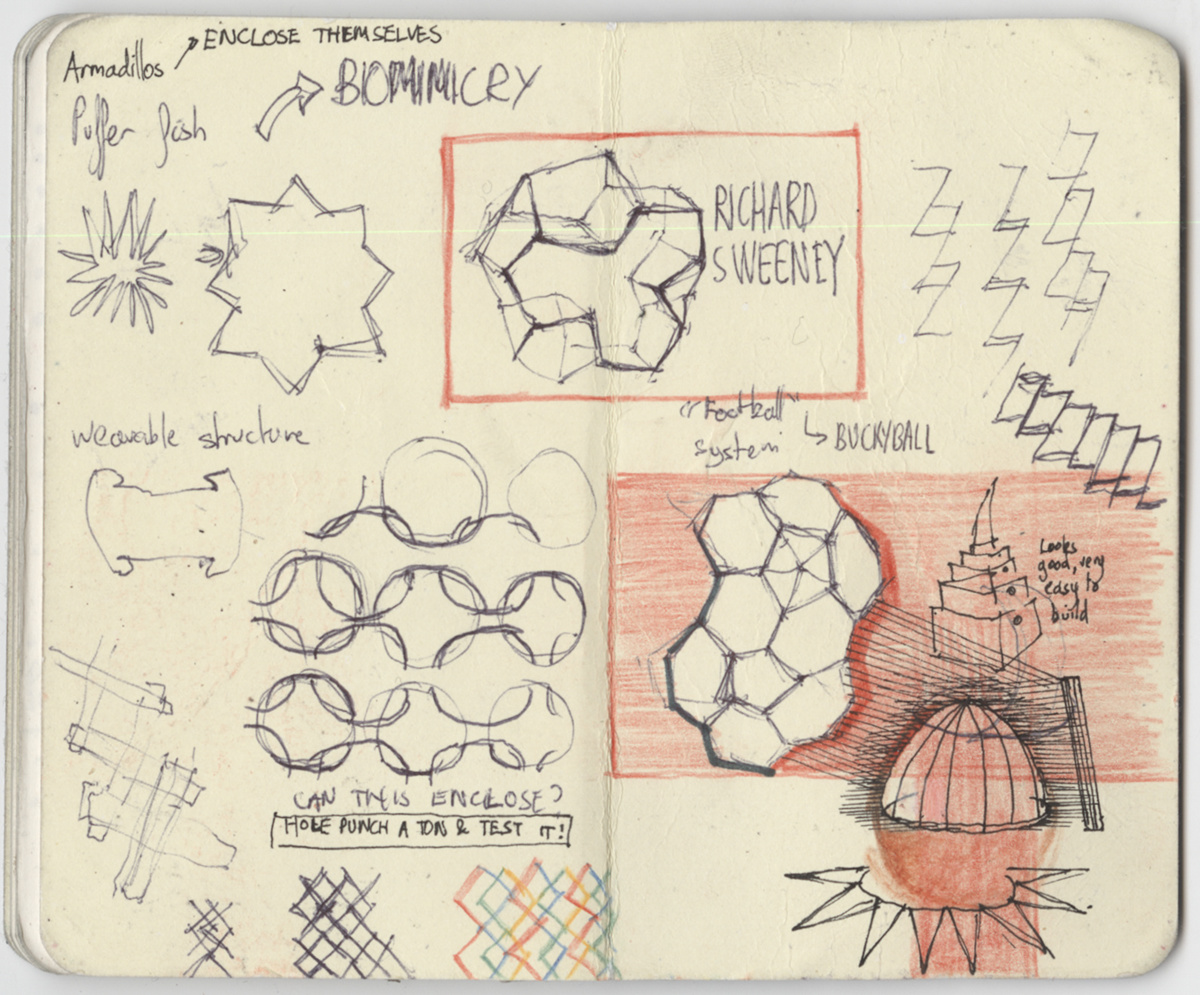

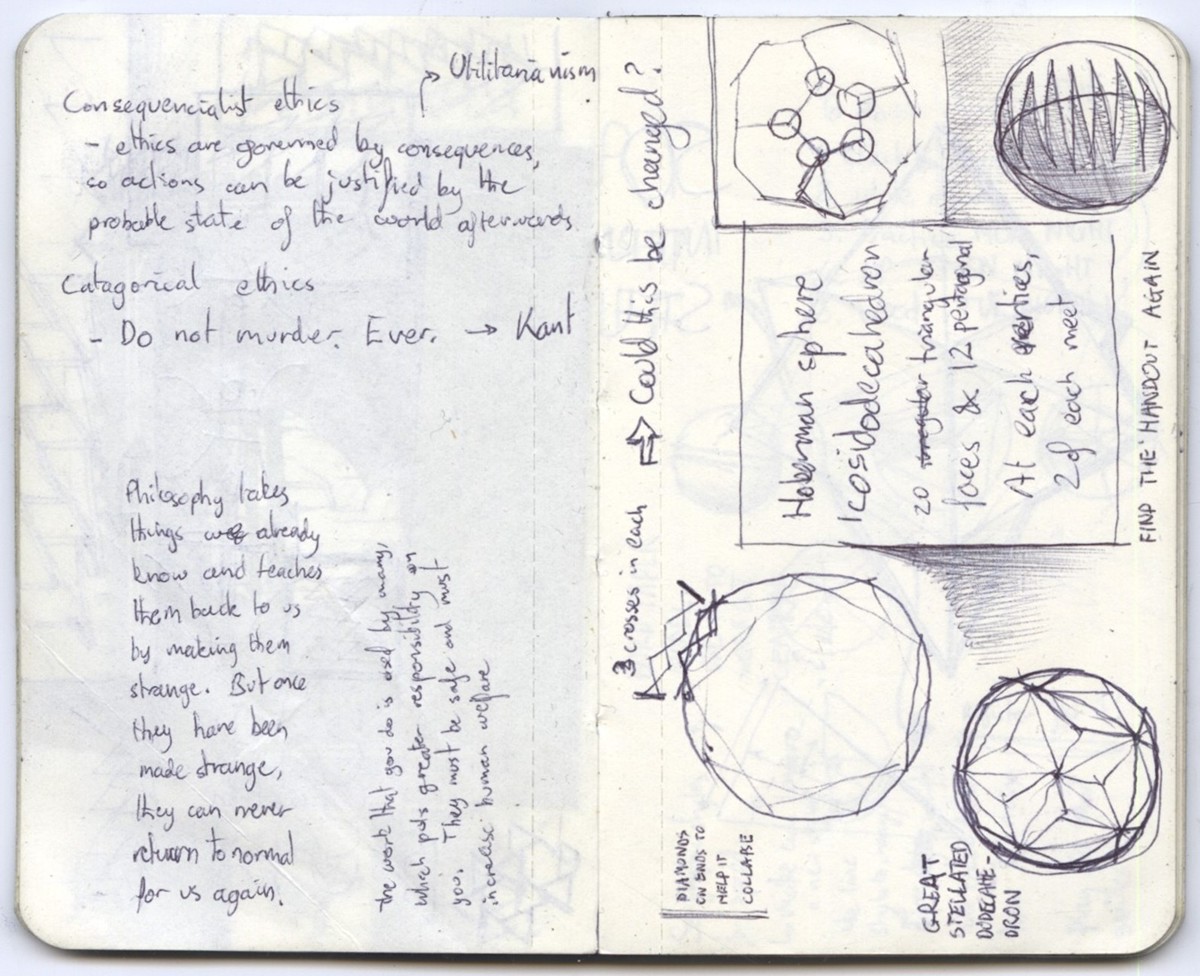

Sketchbook planning for forms in thin tin-plate steel (above and below)

Concepts for unlimited planes executed in metal

The final project for this class was to create either a modular form, and panelled form or an enclosure. The piece made in response to this brief involves all areas of the brief. It has modules in the pentagons and hexagons, but then a second layer of modules exists within that, as identical triangles form every panel. The piece was created to explore the concept of the enclose: how could something be at once open but also enclosed?

Sketches for transforming sheet metal into a complex curve

Models to test complex curvature (above) and industrial fittings (below)

Sketches for planning final form of modular pannelled enclosure

Paper models to plan construction and module structure

First iteration of final form

Final iteration of form

Note the large diameter ball bearing held enclosed but always visible at the centre of the form

Note the large diameter ball bearing held enclosed but always visible at the centre of the form