Implications of Additive Manufacturing Process in Architecture: High Performance Ceramic Facade

In collaboration with Connie Wang and Cristi Baquerizo

The technology of additive manufacturing, alongside with digital computation programs such as Grasshopper for Rhinoceros has allowed for vast opportunities within the design realm. The additive manufacturing process has been associated with small scale printing and has only recently made its way as a viable design and construction solution in architecture, not only printing walls and joinery, but also entire houses and buildings. Given the exceptional benefits in the specificity, accuracy, and customization in design within these platforms, this process lends itself to means of production in the context of architectural customization. This project presents an integrated computational and digital fabrication work processes for a custom high performance ceramic facade system.

Ceramic Facade Prototype

Salt dough was chosen initially because of its consistency and easiness to extrude. The salt dough can also be baked to harden. Clay was chosen as the desired printing material because of its long history as a traditional architectural building material, as well as its accessibility, and abundance. The air-dry clay is an oil-based clay that does not require firing. Given its properties, the layers of extrusions did not bond to one another and it was extremely brittle when dried. The CV90 clay is a mixture of porcelain and coarse sand produced in the RISD Ceramics department. The clay dries a light beige and fires to a clean white; it is extremely durable and provides a clean finished look. The layers of extrusion bind together throughout the drying and firing process.

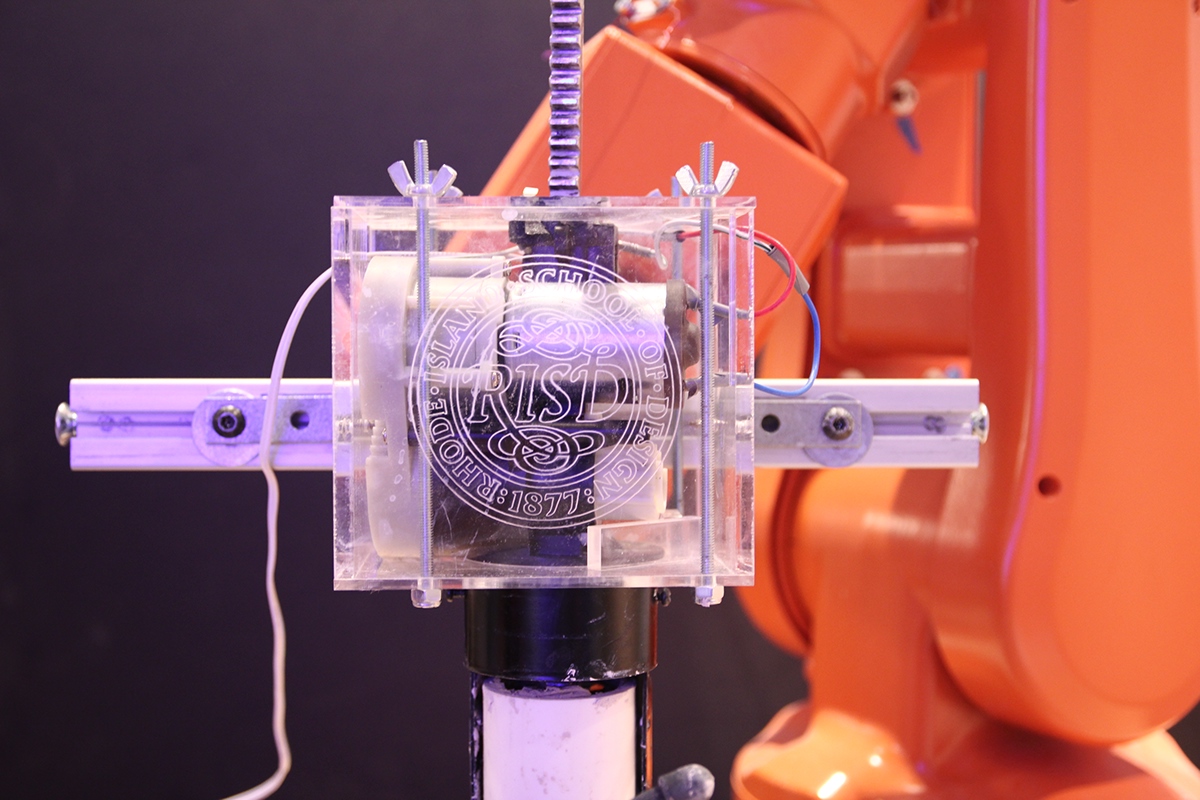

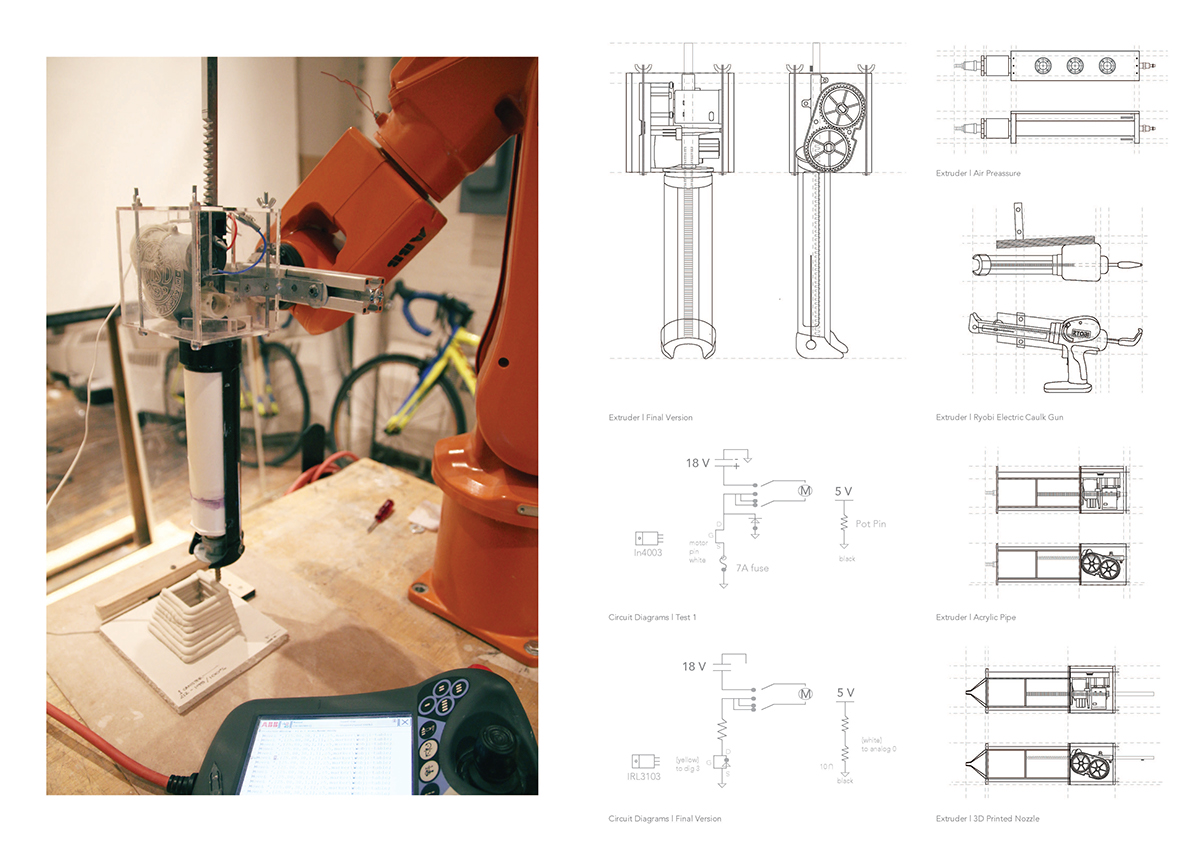

A Series of extruders were developed to eliminate complications as well as optimize the process of extruding clay and production. In our final design, an 18V DV Motor, gearbox and plunger system was taken from a Ryobi P310 caulking gun and rewired to an external control box consisting of an Arduino, a potentiometer to control speed, and a 3-way 6-pin toggle switch to reverse the plunger by reversing the current. By quantifying the speed of the motor, accuracy in controlling the bead size was achieved. The ABB IRB120 robotic arm was used as a 3-axis printer for the printing process.

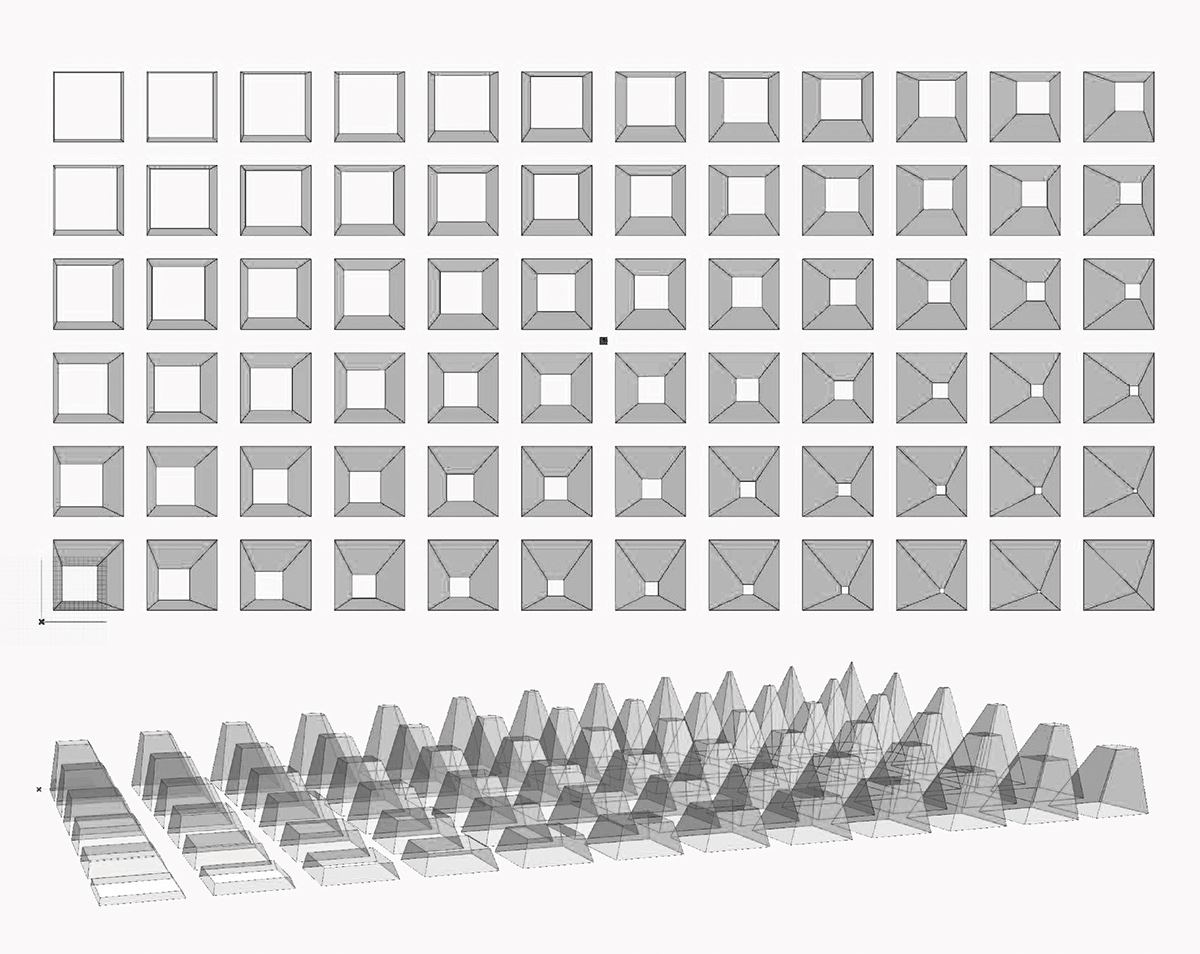

Grasshopper output on Rhinoceros

The self-supporting nature of cones was beneficial to our method of production. By keeping the base and angle of the cone consistent, the aperture or opening of each unit can be varied by adjusting the height. The cones can then be adjusted to tilt within the confines of the base for reasons such as views and glare. To produce the variance, an image sampler was used within the Grasshopper platform. The sampler analyzes a simple black and white gradient and varies the height of each cone, thus apertures.The prototype was generated using a simple gradiant with a maximal degree of tilt on each corner

CASE STUDY: MIT MEDIA LAB

The MIT Media Lab was chosen as a case study and experiment for the 3D printed optimized facade due to its variability in office spaces, studio labs, and gallery spaces on different floor levels along the southeastern elevation. The Grasshopper and DIVA plug-in for Rhinoceros work concurrently to generate and assess fabrication models in terms of daylight. The façade acts as a light filtration system, affecting the interior lighting conditions.

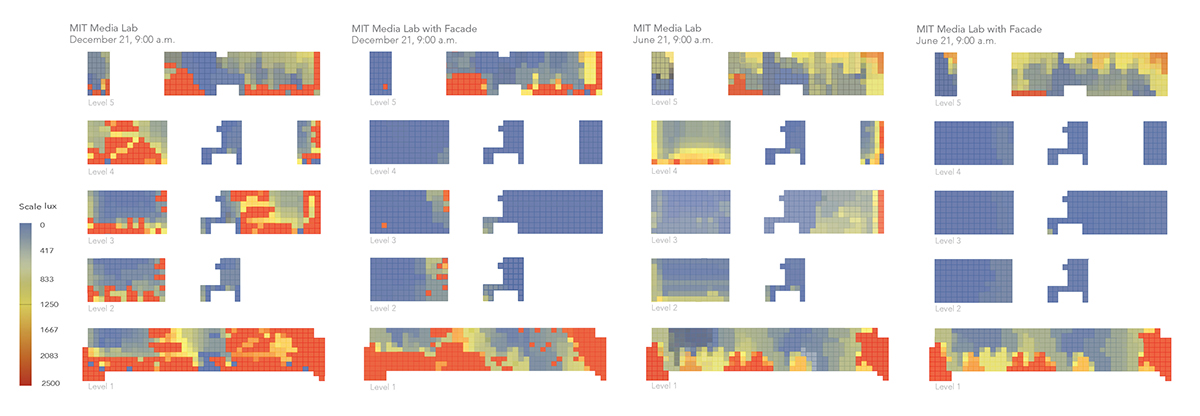

Digital simulations were run on the DIVA, a plug-in for Rhinoceros, in order to draw conclusions regarding the interior lighting conditions assessing the required facade conditions and determine the design parameters. Specific to location, time and day of a year, daylight grid simulation taken at 3’ and daylight image visualizations were used to determine, in lumens, how much natural light the building received with and without the façade.

DIVA Illuminance Nodes Analysis of the MIT Media Lab taken on December 21st 9:00am and June 21st 9:00am with and without facades

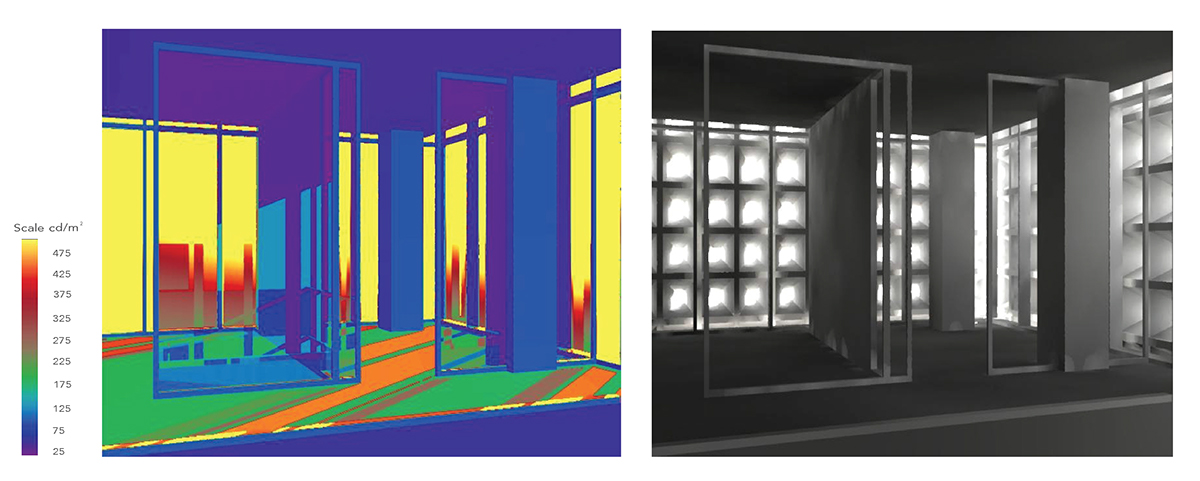

(Left) False Color Image of the office space within the MIT Media Lab on June 21st 9:00am. (Right) HDR image of the office space within the MIT Media Lab on June 21st 9:00am. Note: Interiror lighting is not accouted for.

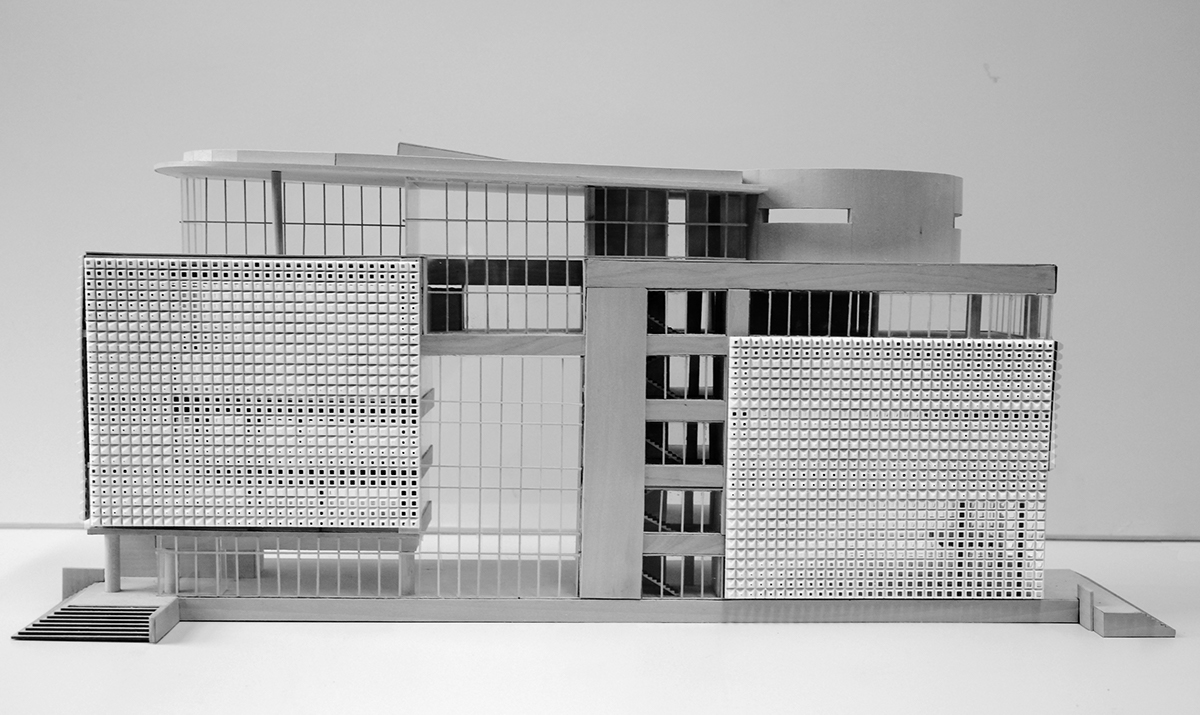

Exterior Rendering of MIT Media Lab with high performance facade

1l8" - 1'0 Scaled Model of the high performance facade system attached on to the MIT Media Lab

Exterior and Interior view of the model with the high performance facade