Reconfigure

Aluminum Project

Metals I

Fall 2014

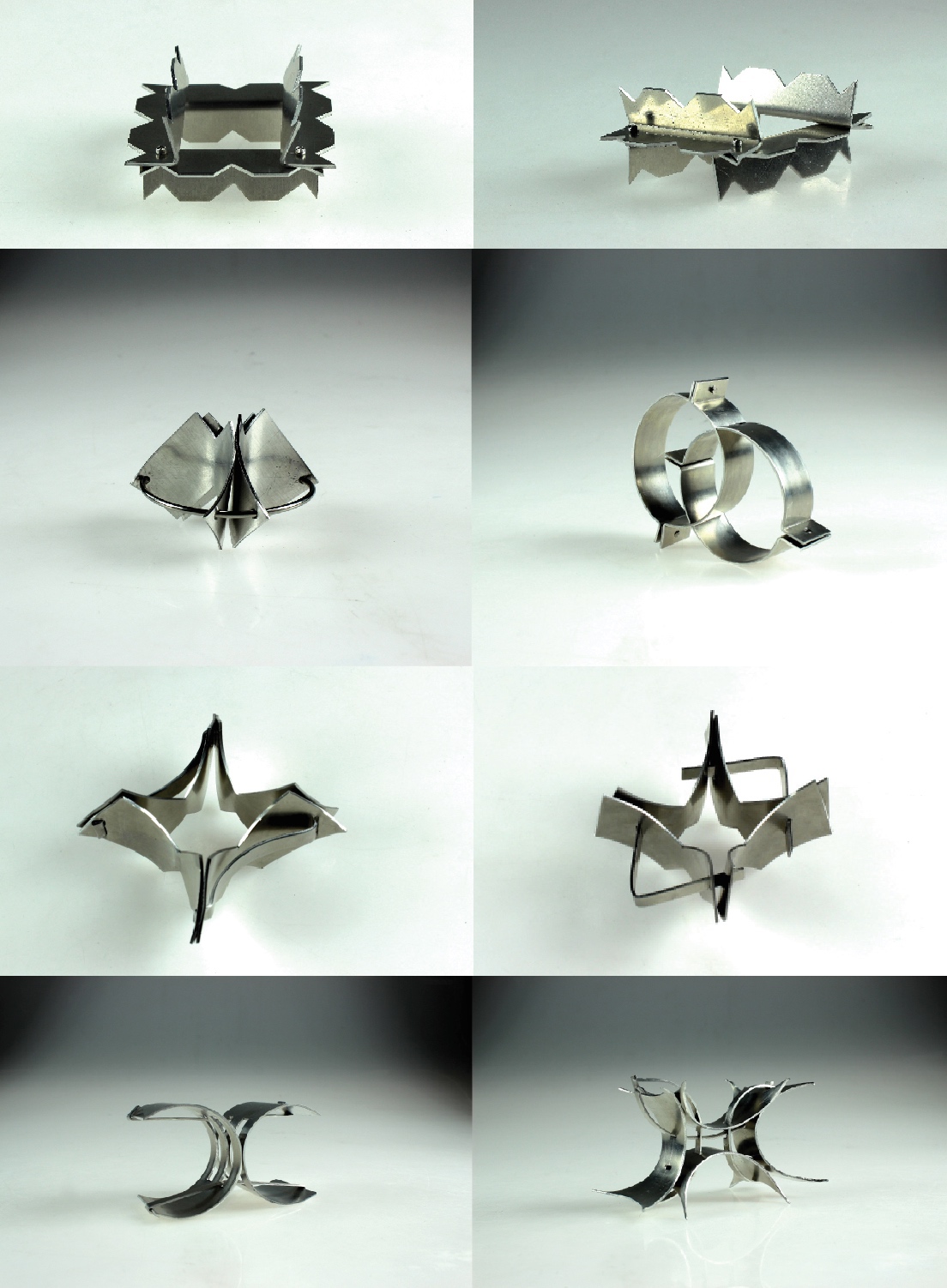

FORM & MATERIAL EXPLORATIONS

Early aluminum studies aiming at the understanding of the material.

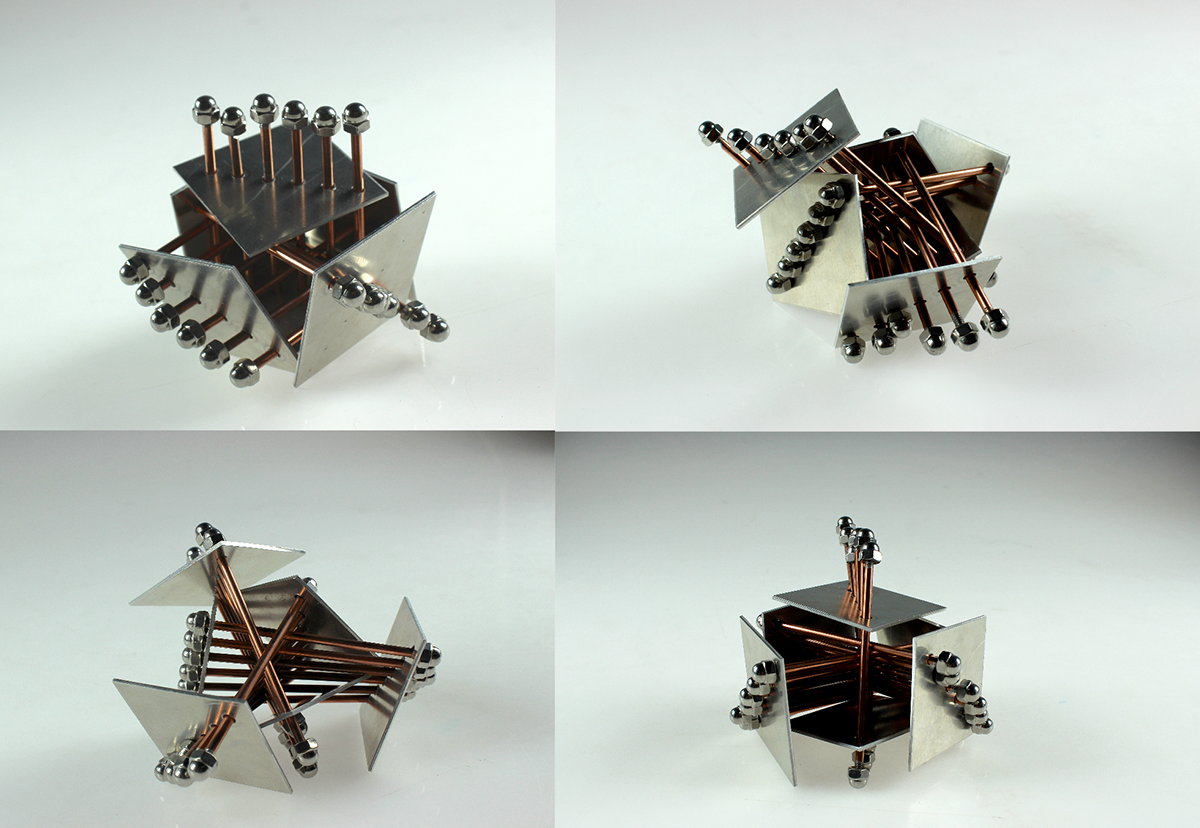

CUBE 1.0

Sketch model for first aluminum cube design.

Things to consider: too much hardware.

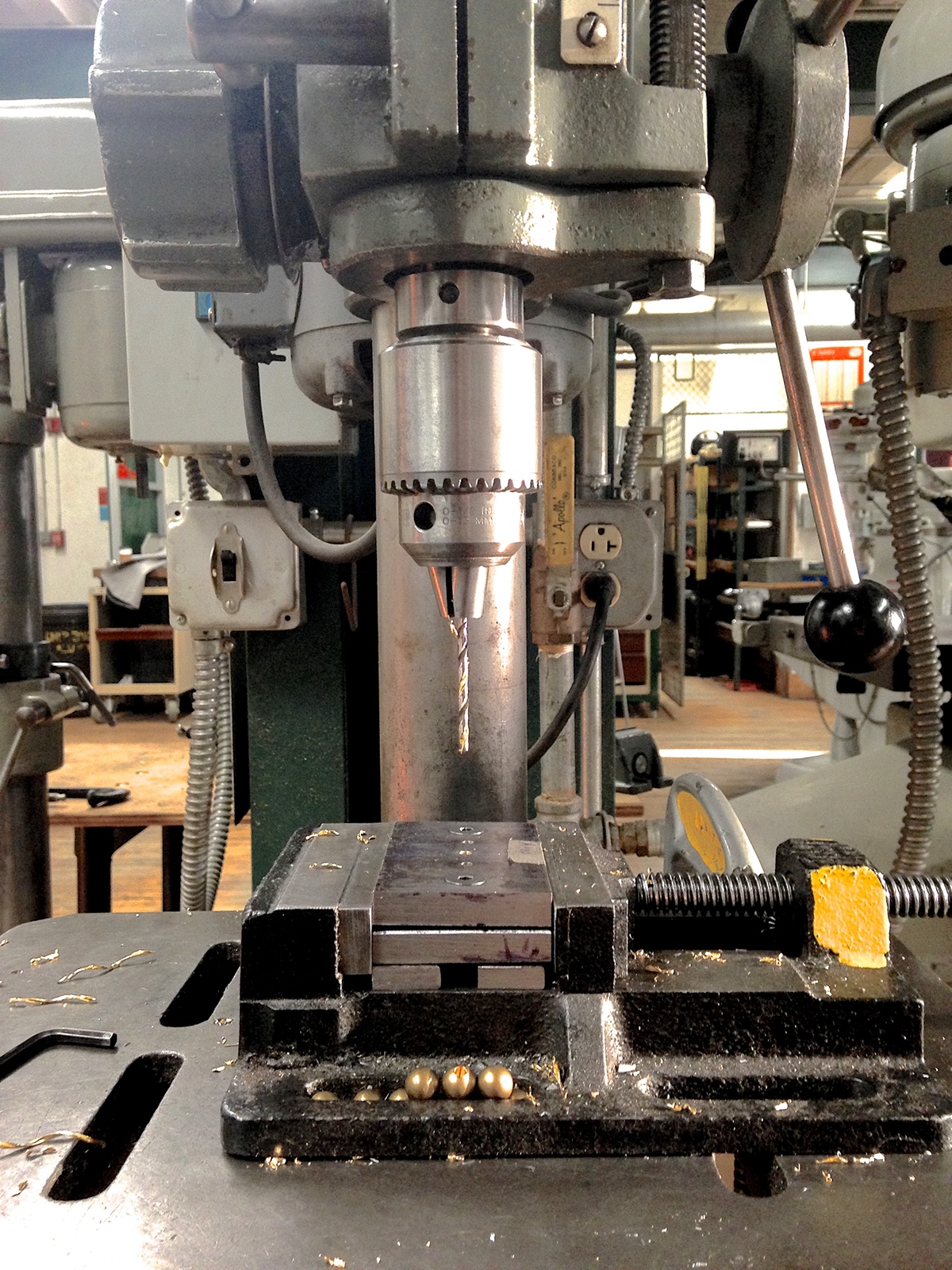

I decided to replace the acorn nuts from the model with brass spheres. In order to attach brass rods to the spheres I had to figure out a way to drill holes in them in order to press-fit them together.

To do this, I made a jig that enabled me to clamp each sphere by placing it between two steel blocks, screwing them together and then drilling.

My first finished object was a cube, the faces of which were movable, since they were attached to the opposite faces with rods and held together by the brass spheres.

The challenge: assembling the cube.

The frustration is inevitable and fully intentional.

16 gauge aluminum, brass welding rods, brass spheres

detail

detail

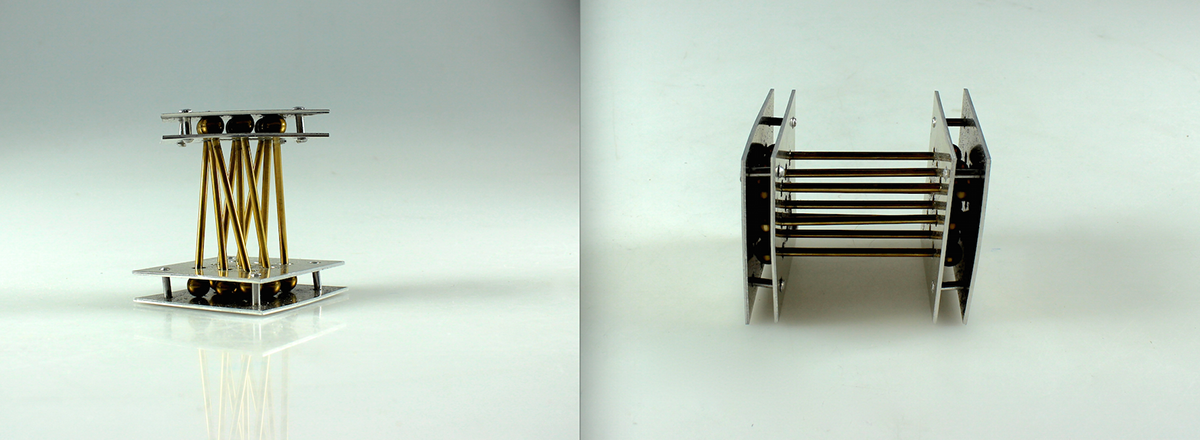

CUBE 2.0

Sketch model for second aluminum cube.

My second final object uses the same sphere-rod innvovation to approach the concept of a cube rather differently. It, too, has the ability to move and reconfigure itself and continues to challenge one to construct a cube, only this time in a more smooth and satisfying way.

front view

side view

16 gauge aluminum, brass welding rods, brass spheres, brass tubing

Thank you for viewing!