Laminated Acrylic Sheet and Steel Rod

(Flame polished)

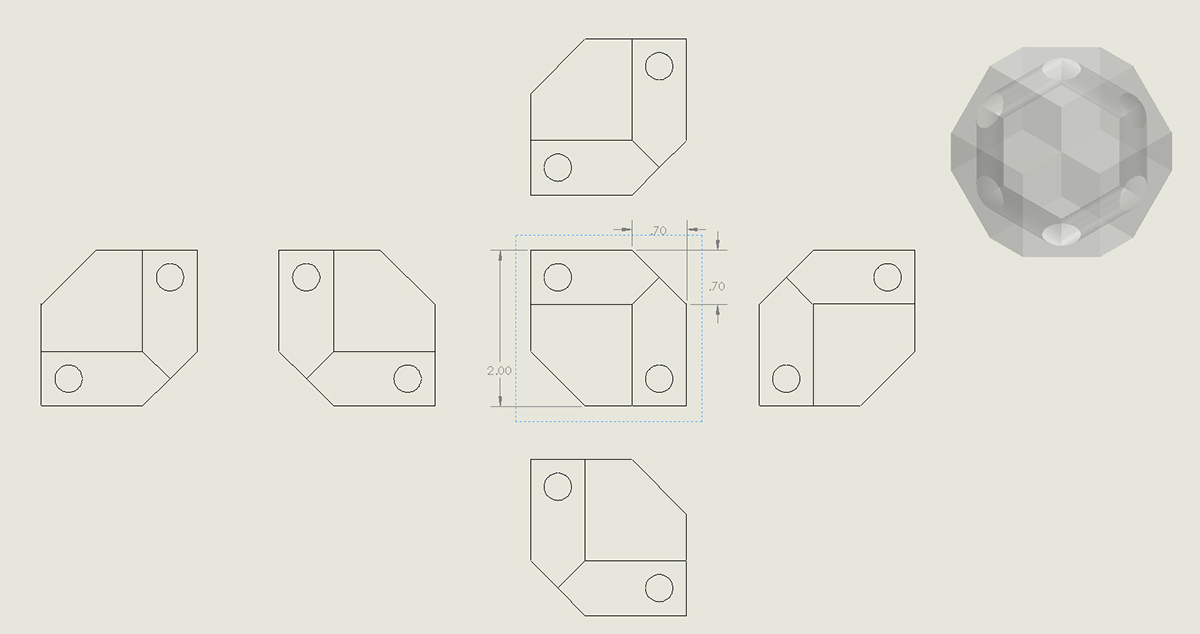

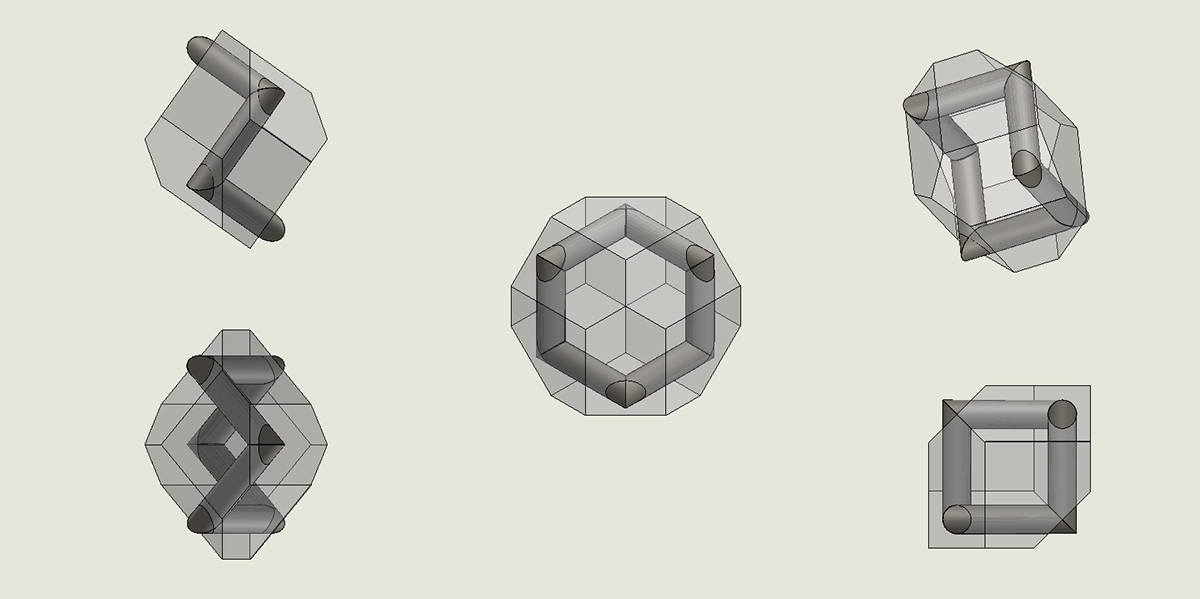

I began by fleshing out my concept in Solidworks in order to fix potential problems early on, like making sure it can be held in a vice for all of the cuts, and that the angles were possible to accomplish.

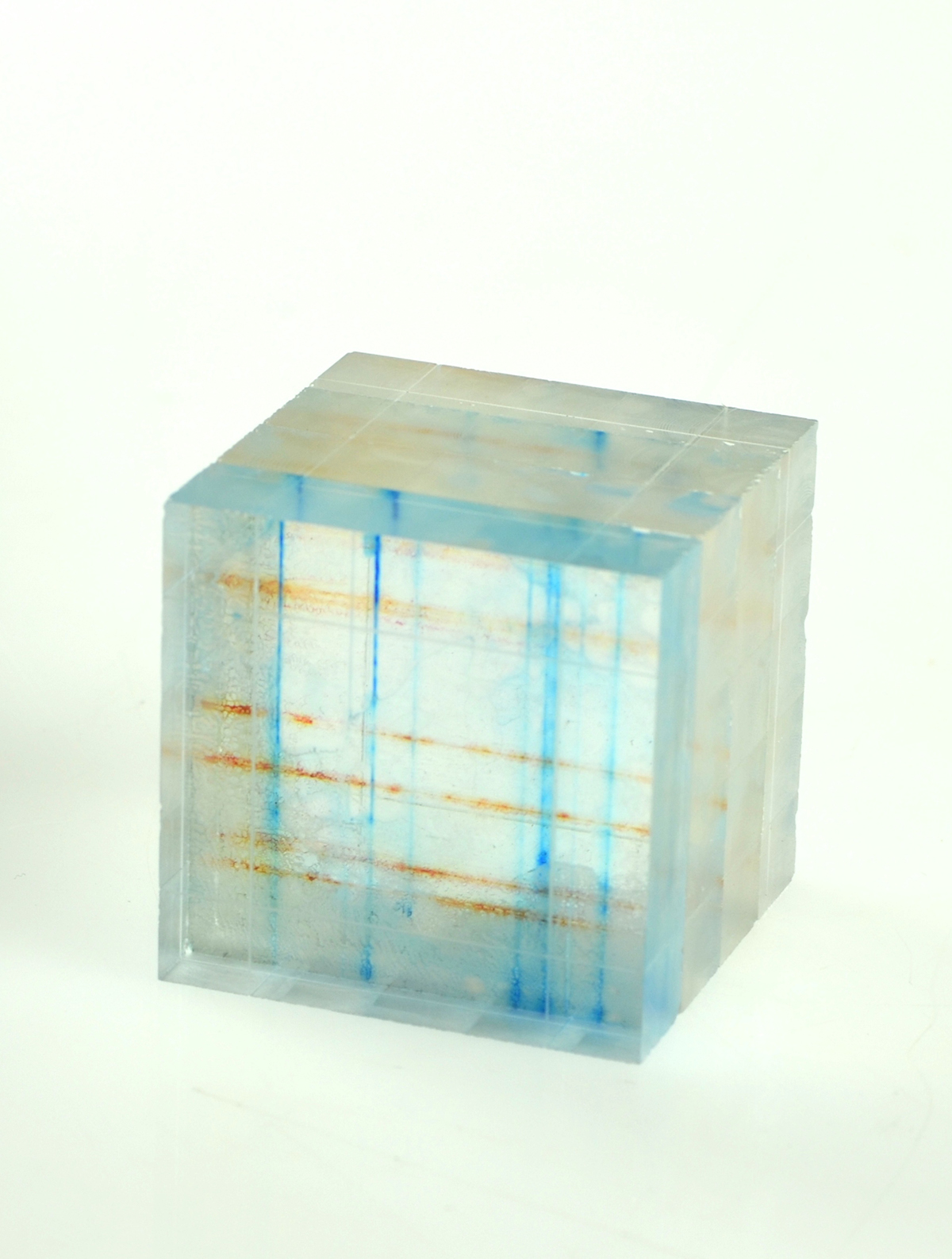

The pieces all began as acrylic sheets laminated on top one another and then cubed on the vertical milling machine. The holes were drilled second, and facets were milled last. Only the final piece was flame polished, all the others were left with the original texture from the milling process.

The 6 steel rods were turned on a metal lathe and then transfer to the milling machine to get the angle on the ends. Then, they were very patiently hammered until they fit , never to come out again!

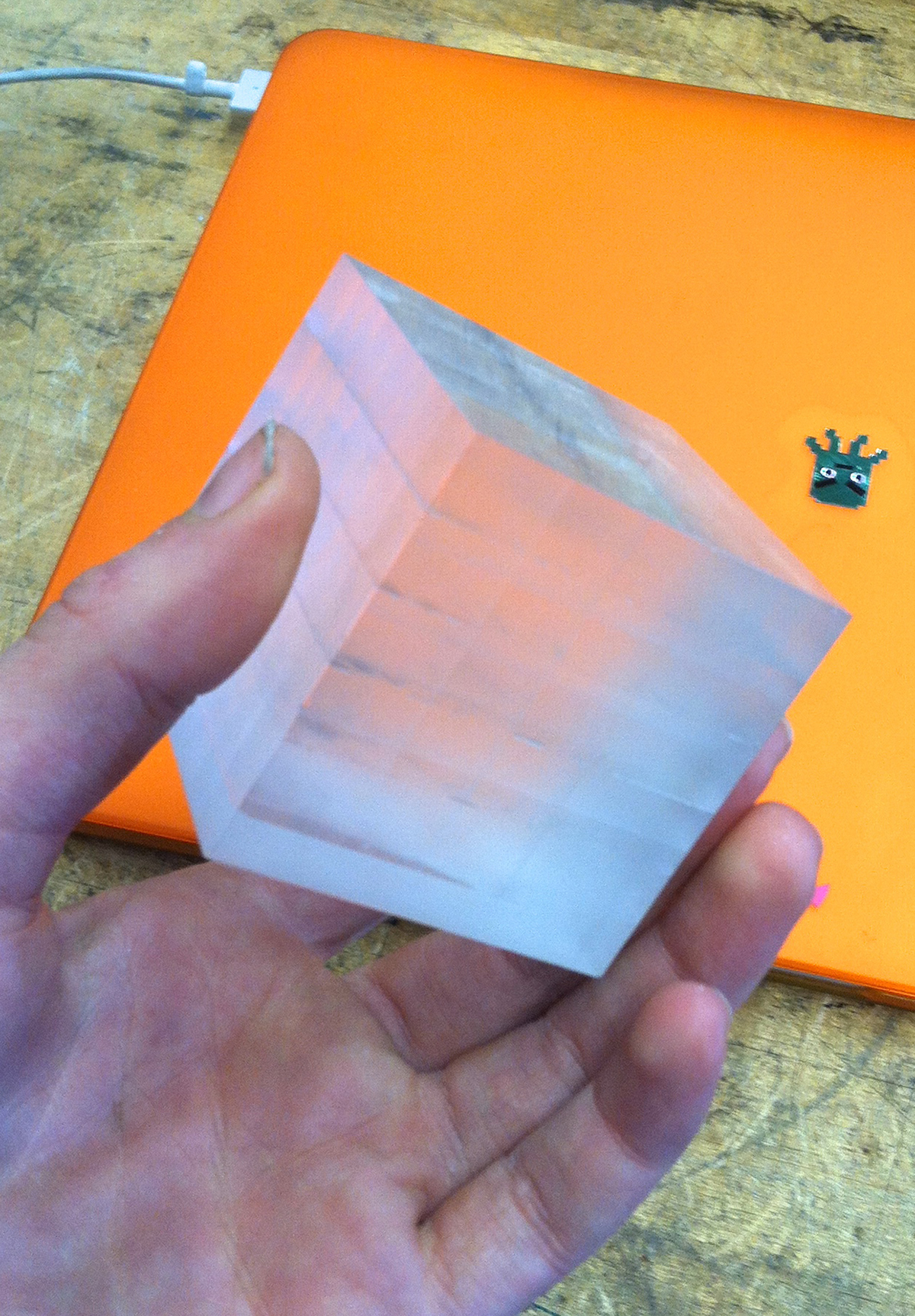

This was my first attempt working with the laminated Acrylic. I got a good feel for the material and its weaknesses. Sadly, one of the corners blew out as I was drilling in, which inspired me to do experiment more with next batch of cubes.

With these, I focused on the adding elements during the laminating process like adding scribing, drawing, and coloring.

Work in progress.