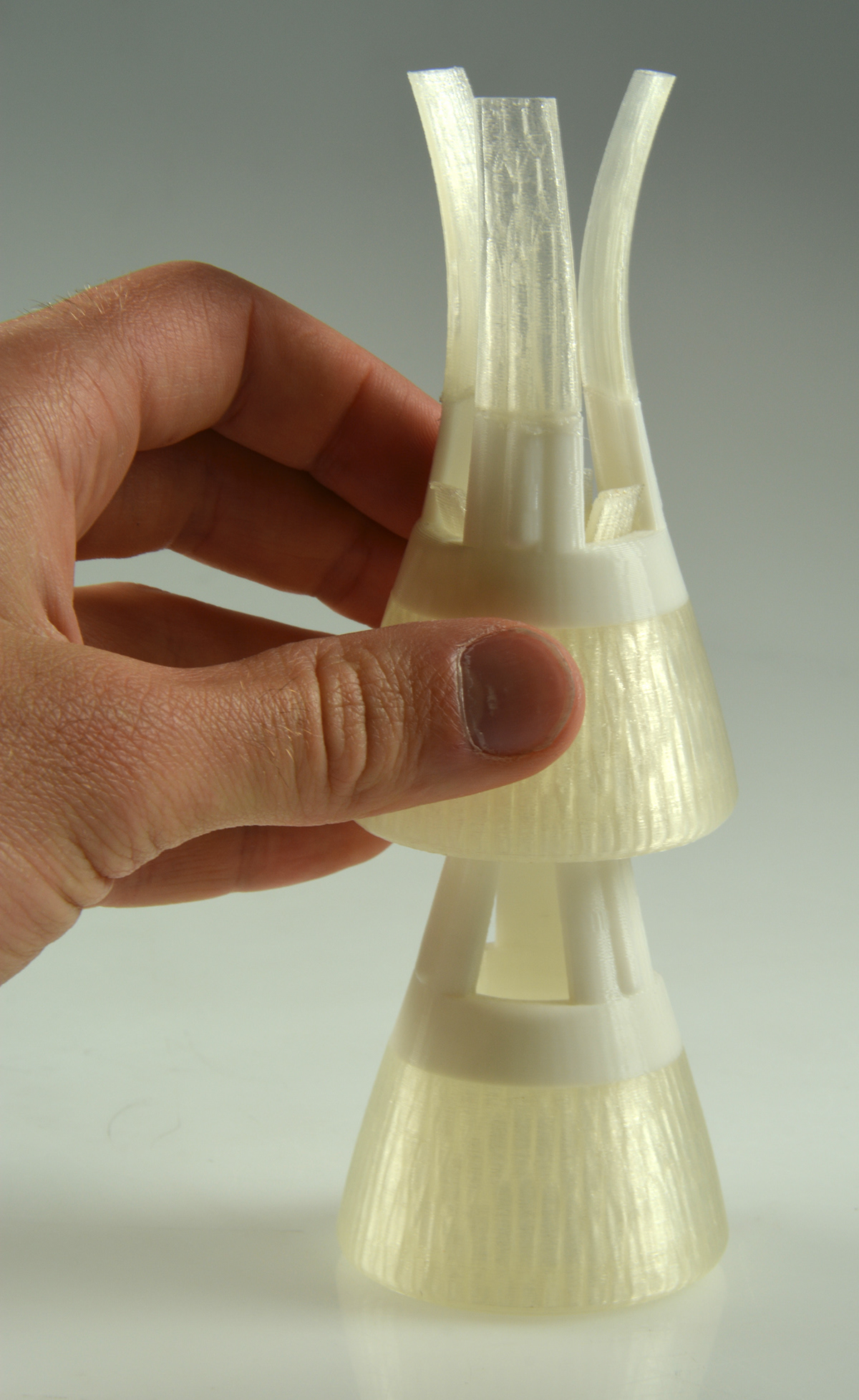

Intended to challenge spatial thinking and how two objects can be designed to interlock, this project encompassed many aspects of the prototyping process. Starting with thumbnail sketches and moving on to 3D Rendering after settling on a design, I had to go back and forth between the modeling and making process. Each time I 3D printed the connection I learned about the limits of the printing technology and was able to alter my design to accommodate those limitations. By using two different filament materials within one print I was able to incorporate flex points to the design. Manually pausing and changing from ABS filament to the very pliable Polyflex filament then back to ABS enabled my connection to be successful.

My connection method as I originally envisioned it . The print failed due to parts being smaller than resolution of the printer.

Top View of final 3D model.

Isometric View of final 3D model.

Section View of final 3D model.

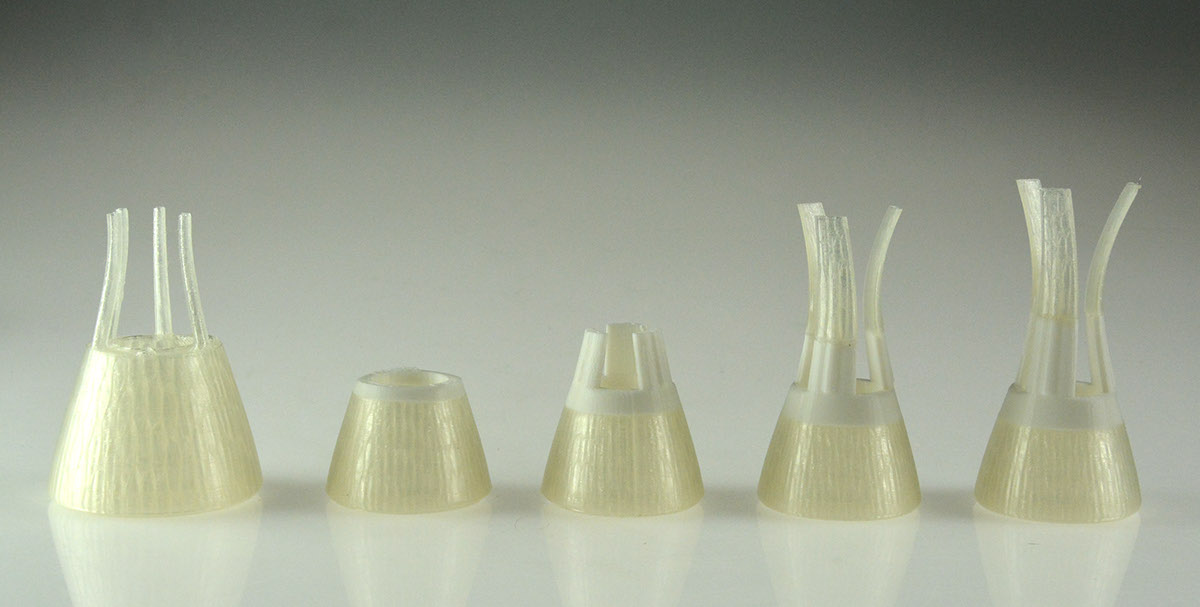

Progression of 3D prints showing how the design progressed and how I learned from my mistakes when attempting to print with two separate types of filament.

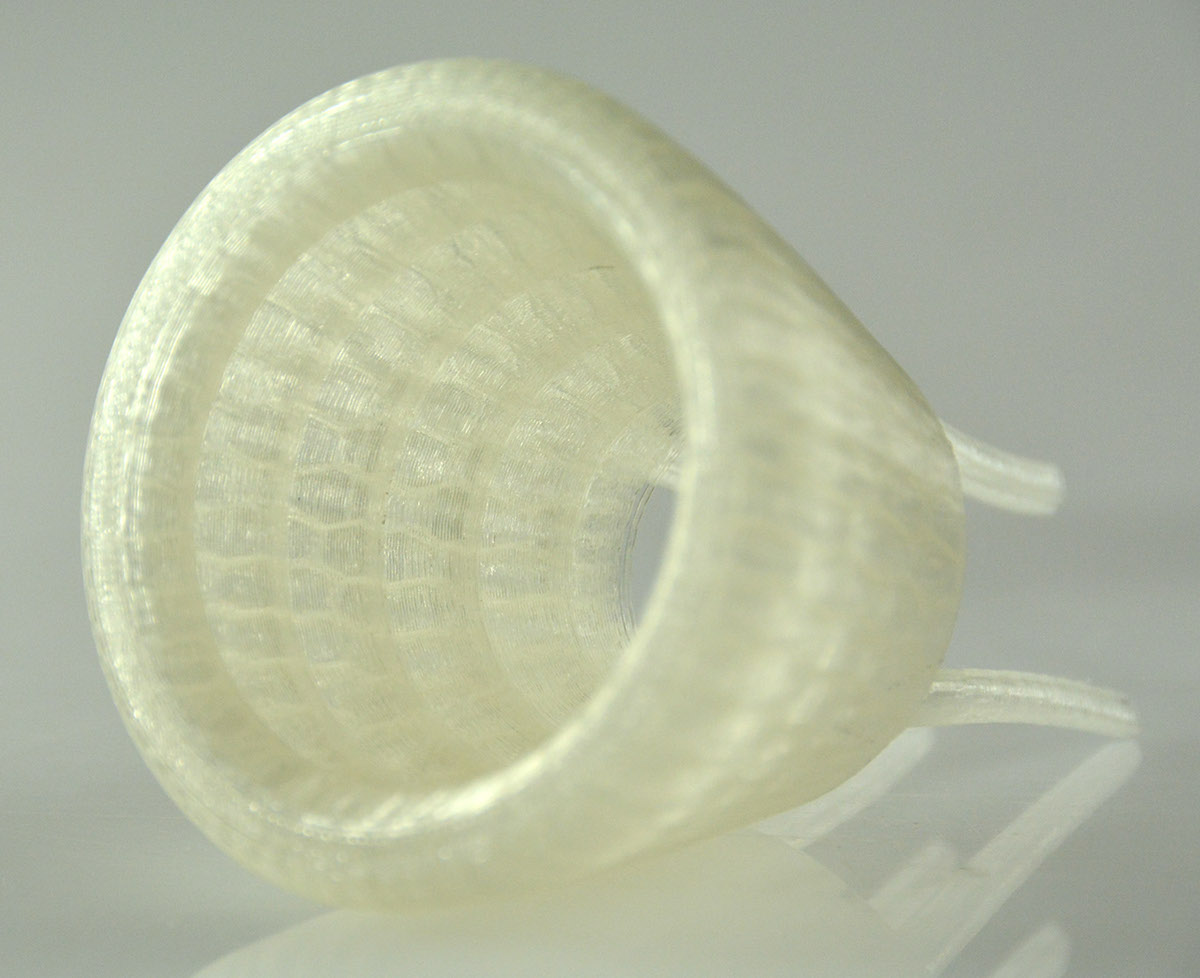

Interior ridges of the main body produce a clicking sound as the connection is made.

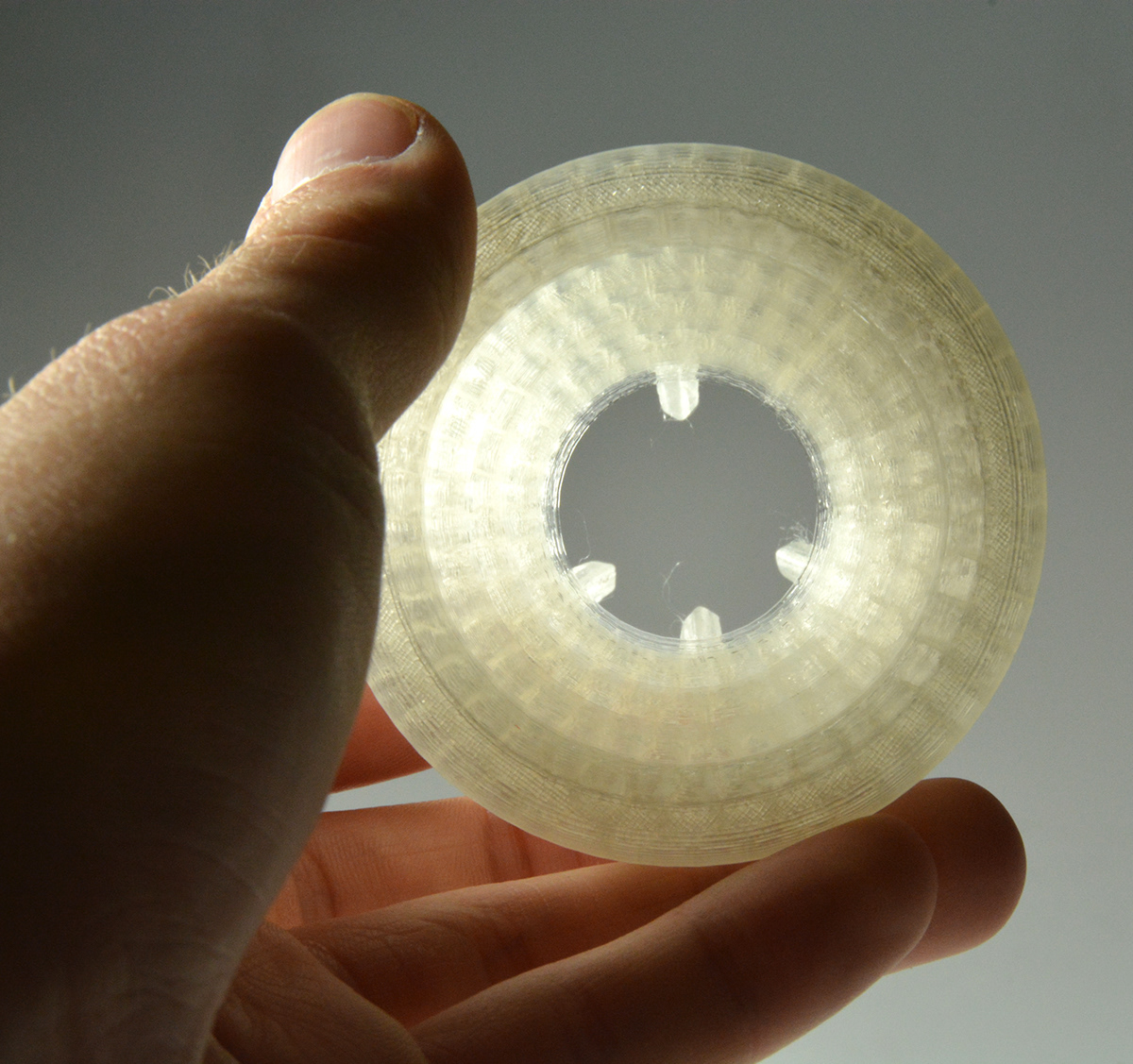

Connection being made.

Final connection.

Final print with successful combination of flexible filament and normal ABS.