Medical packaging can be a complex design challenge. Strict requirements often lead to material hungry solutions.

Compared to other FMCG sectors, the medical industry has been slow to reduce packaging and adopt more sustainable behaviours due to more stringent requirements and regulation.

Moreover, medical devices and medications must be well protected during transit, remain hygienic or sterile and be intuitive and usable for the end user.

A typical packaging configuration in the medical sector has many components and a large range of materials.

More needs to be done to reduce the quantity and variety of materials used to support a more circular economy. Currently, disposable packaging such as boxes, and bubble wrap amount to two third of general medical waste.

More needs to be done to reduce the quantity and variety of materials used to support a more circular economy. Currently, disposable packaging such as boxes, and bubble wrap amount to two third of general medical waste.

Aide is a packaging system for a respiratory ventilator, with special attention to renewable materials and circularity in the medical environment. It significantly reduces surplus materials by combining structural and secondary packaging in a single component. The form factor is designed to provide robust structural support to the internal components with performance comparable to existing multi-layer packaging.

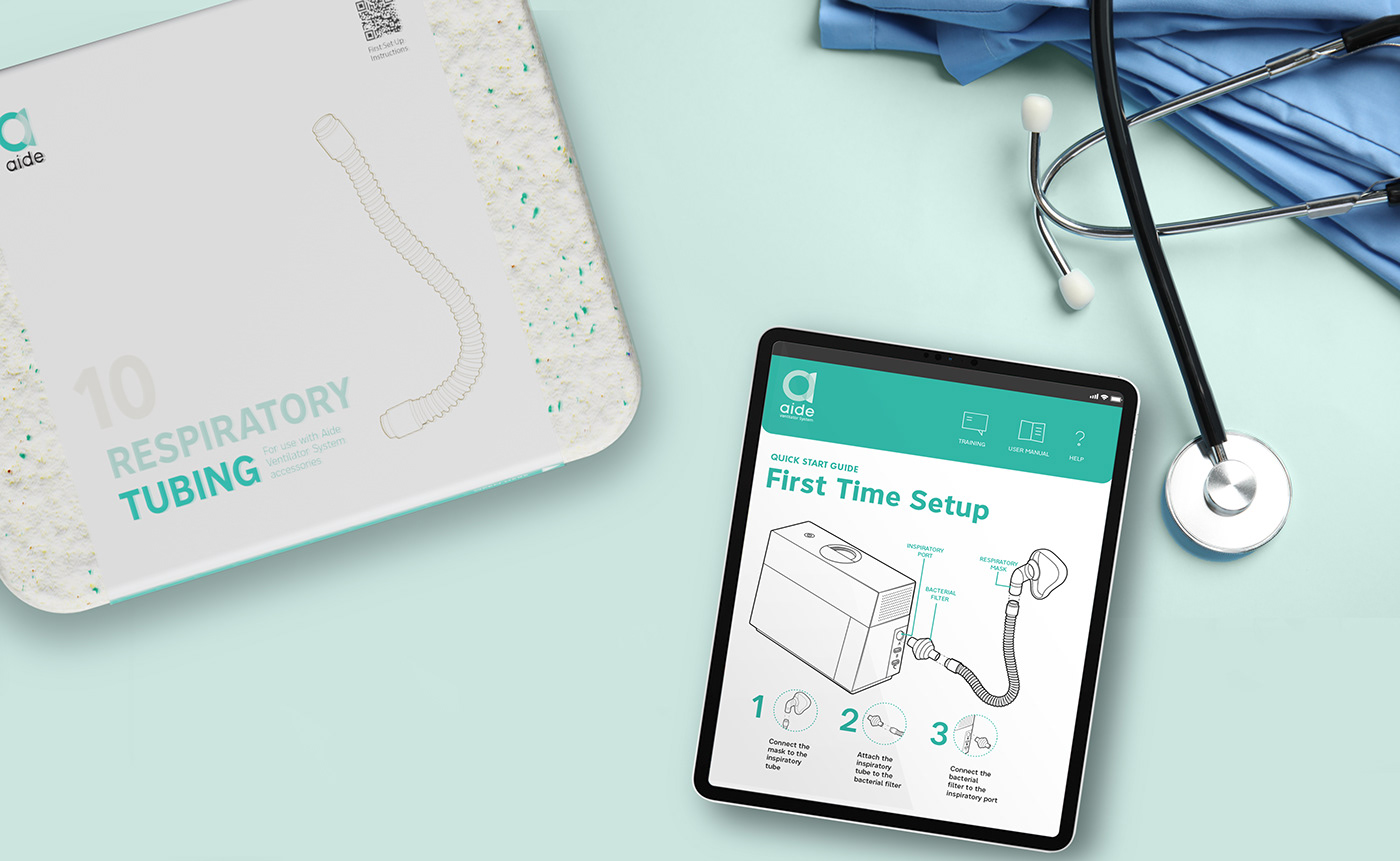

Aide utilizes digital touchpoints to improve the user experience and further reduce the amount of packaging.

Unboxing is an opportunity to reveal instructions to the user, clearly guiding them through correct setup and use.

To do this Aide utilises a digital Quick Start Guide accessed via a QR code. The digital guide includes training, instructions, and consumer assistance.

To do this Aide utilises a digital Quick Start Guide accessed via a QR code. The digital guide includes training, instructions, and consumer assistance.

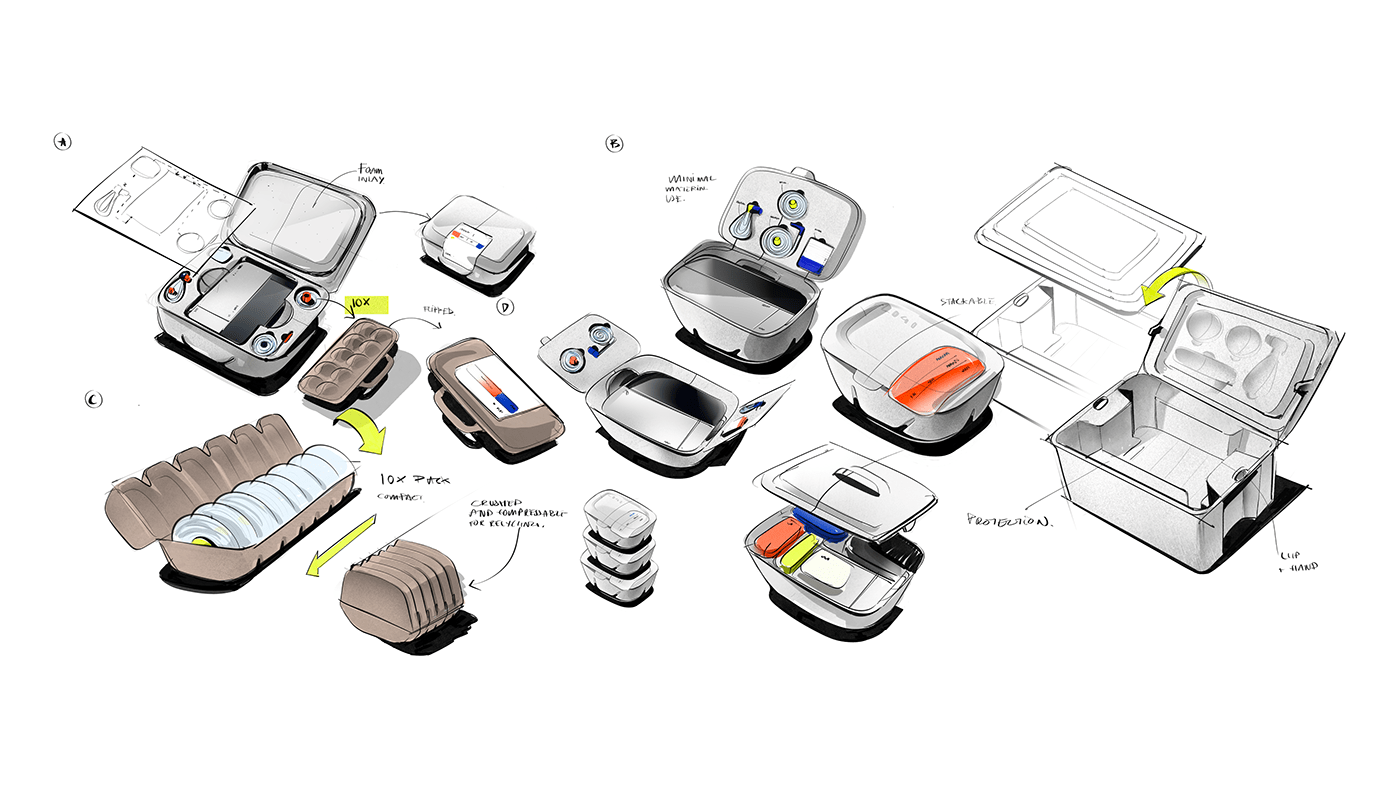

We arranged a workshop to focus the mission, identifying key challenges to tackle: from defining the mission statement, to understanding sustainable materials, functional constraints and brand identity.

Our sketching session explored different possibilities in terms of components arrangements and structural packaging to maximise the use of space and materials.

The packaging is innovatively designed to provide both structural support for the content inside and affordances for easy handling. The external packaging can be reused for hospital storage and shipping back the device to the manufacturer when malfunctioning, bringing more longevity to the packaging and less single use nonsense.

An honest medical packaging solution that really cares.

Sustainable medical packaging requires a more innovative approach. Aide is a new type of packaging system that hasn’t been seen in the medical industry before. This solution combines structural and secondary packaging so that unnecessary material is removed. Modularity is one of the key aspects of Aide: a better space arrangements of the components enables an optimal volume usage and therefore reduces carbon footprint during transit.

Traditional packaging has a complex manufacturing process, combining many different materials and techniques. Aide significantly reduces supply chain complexity, resulting in lower carbon emissions, while helping medical companies meet social responsibility goals and elevate brand values of honesty and social responsibility.

This content was originally posted on Cambridge Consultants' website. Cambridge Consultants develops breakthrough products, creates and licenses intellectual property and provides business consultancy in technology critical issues for clients worldwide. For more than 50 years, the company has been helping its clients turn business opportunities into commercial successes, whether they are launching first-to-market products, entering new markets or expanding existing markets through the introduction of new technologies.