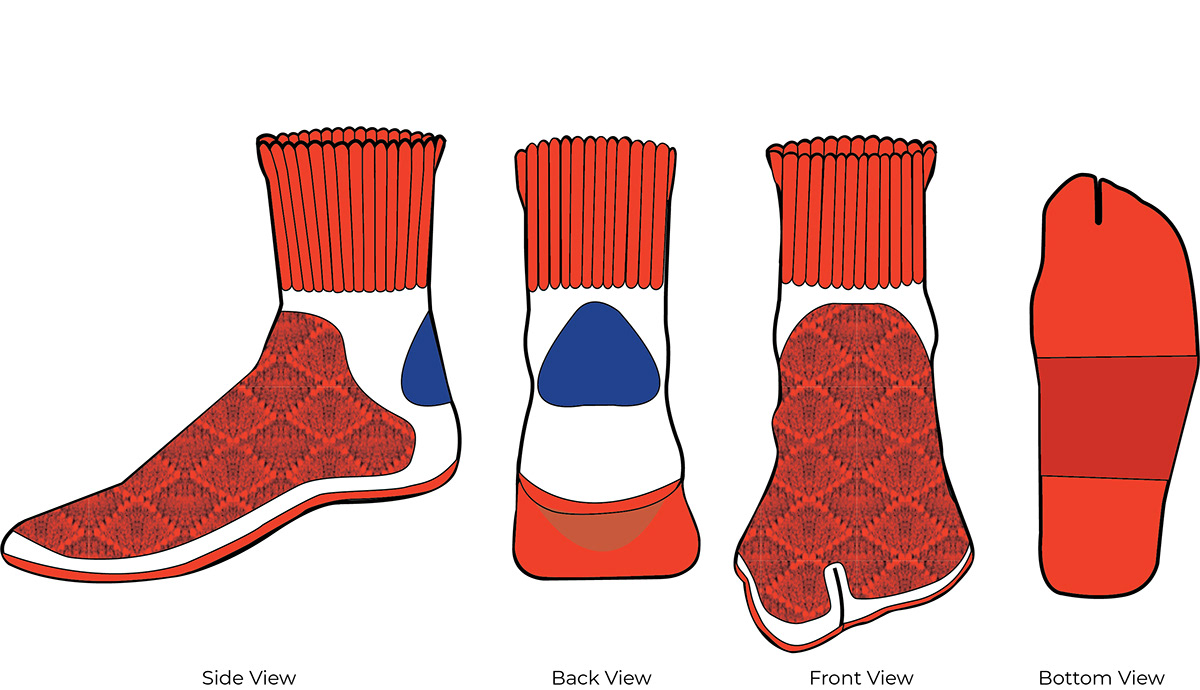

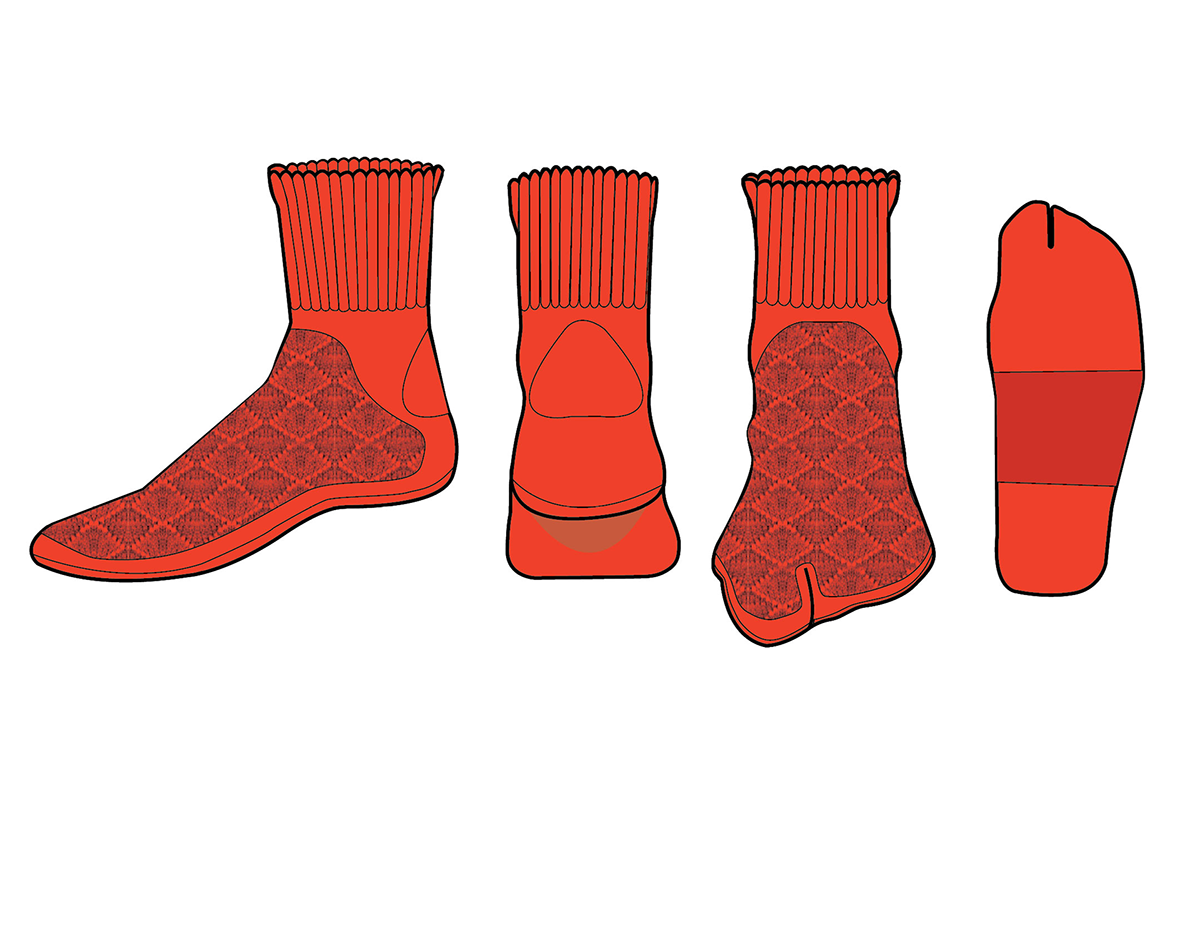

Final Illustration of Microgravity Footwear, with NASA color scheme.

The Microgravity Footwear project was on the development of footwear to be worn by astronauts aboard the International Space Station (ISS) or other spacecrafts. The item of footwear proposed was designed to protect astronauts feet, which are used frequently for movement and keeping themselves in place, and to optimize comfort and utility.

My research and final design were presented to the NASA Soft Goods Lab and NASA astronaut Don Pettit. After their review the project was approved to begin prototyping, which is currently underway.

To support my research I was awarded the Rhode Island Space Grant.

Throughout the course of my internship I devised and worked on 3 independent projects--Microgravity Footwear, the Artemis Wayfinder, and The Artemis Collection.

The Challenge

"The calluses on your feet in space will eventually fall off. So, the bottoms of your feet become very soft like newborn baby feet. But the top of my feet develop rough alligator skin because I use the top of my feet to get around here on space station when using foot rails"

- NASA astronaut Scott Kelly, January 23, 2016.

NASA astronaut Scott Kelly speaking at NASA headquarters after returning to earth.

Russian cosmonaut Oleg Kononenko aboard the ISS using his feet for stability.

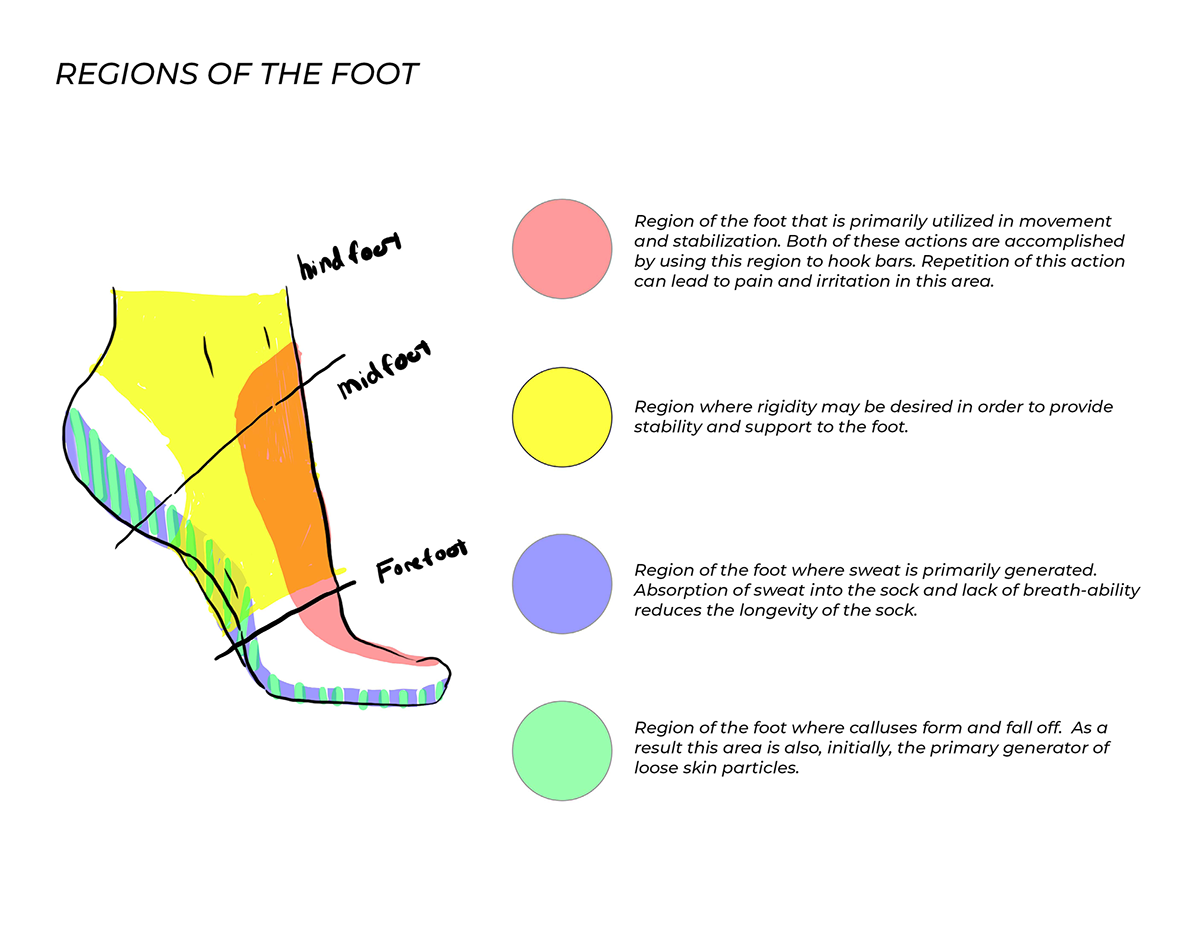

In microgravity astronauts do not walk, but rather float.To maneuver or hold themselves stationary they hook their feet under bars and other straps attached to the sides of the spacecraft. This causes the tops of their feet to be rubbed raw while the bottoms of their feet lose all their calluses, as the pressure and friction needed to maintain them is gone. In addition, the reduced gravity means less blood flow into the feet and loose skin particles will float into the atmosphere.

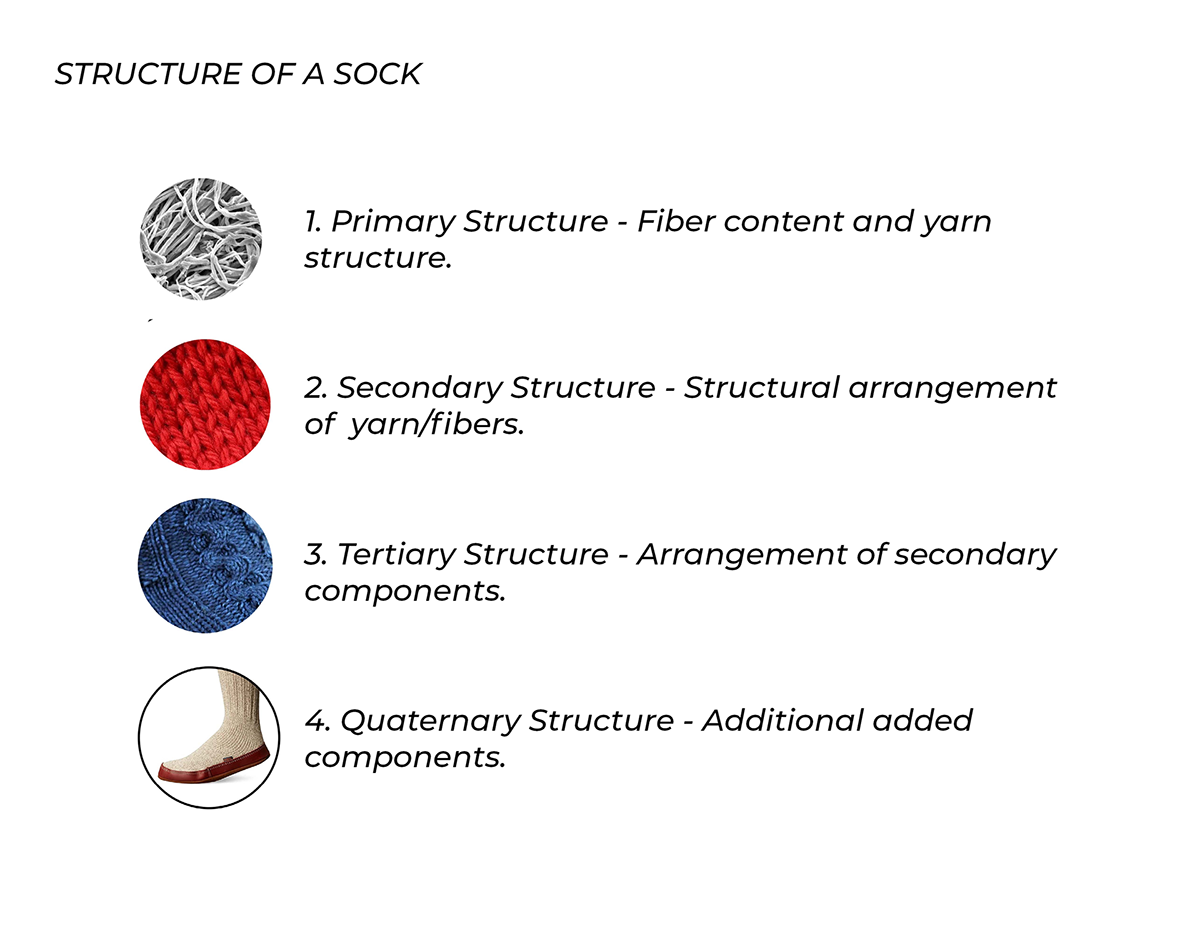

The footwear currently utilized by astronauts is plain, off-the-shelf socks.The goal of this project was to design footwear to address these problems, while also making sure not to interfere with the mobility of the foot and to conform to atmosphere exploration material safety standards. Two additional criteria were to use 3D knitting technology and to find ways to increase the lifetime of the footwear, as clothes in Space aren't washed (current lifetime is 3-4 days).

Based on the information above the following design criteria was developed:

1. Reduce irritation and pain that occurs on the tops of the astronauts feet.

2. Reduce release of skin particles into the microgravity environment during sock removal.

3. Conform to atmosphere exploration saftey standards.

4. Optimize the lifetime of the footwear.

5. Utilize 3D knitting.

Shimaseki 3D knitting machine.

Challenge Breakdown

To begin this challenge, I identified the regions of the foot where the challenges outlined in the design criteria occurred. From this I knew where the solutions I developed would need to be employed.

Next, I broke down the structure of knit footwear in order to understand all the different levels of structure solutions could be applied.

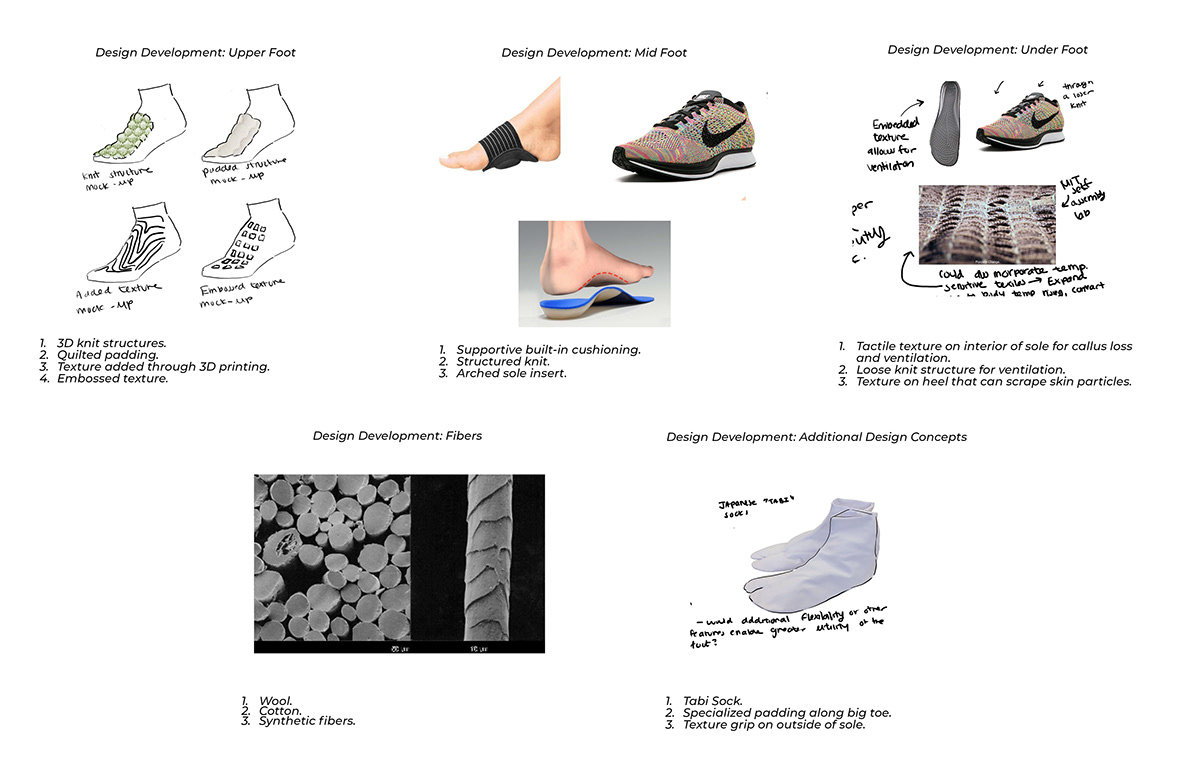

Research and Design Development

Using the two frameworks outlined above, the regions of the foot and the structural levels of knit footwear, I researched potential solutions to the issues presented in each region and considered what structural level they would be applied at. I also noted the advantages and disadvantages of each solution in order to decide which solutions would ultimately be selected.

Throughout this research process I consulted with aerospace textile engineer, Drew Hoyle, and representatives from Shimaseki, a machine knitting company that assisted in fabrication.

Key takeaways from research and design development.

Final Solution

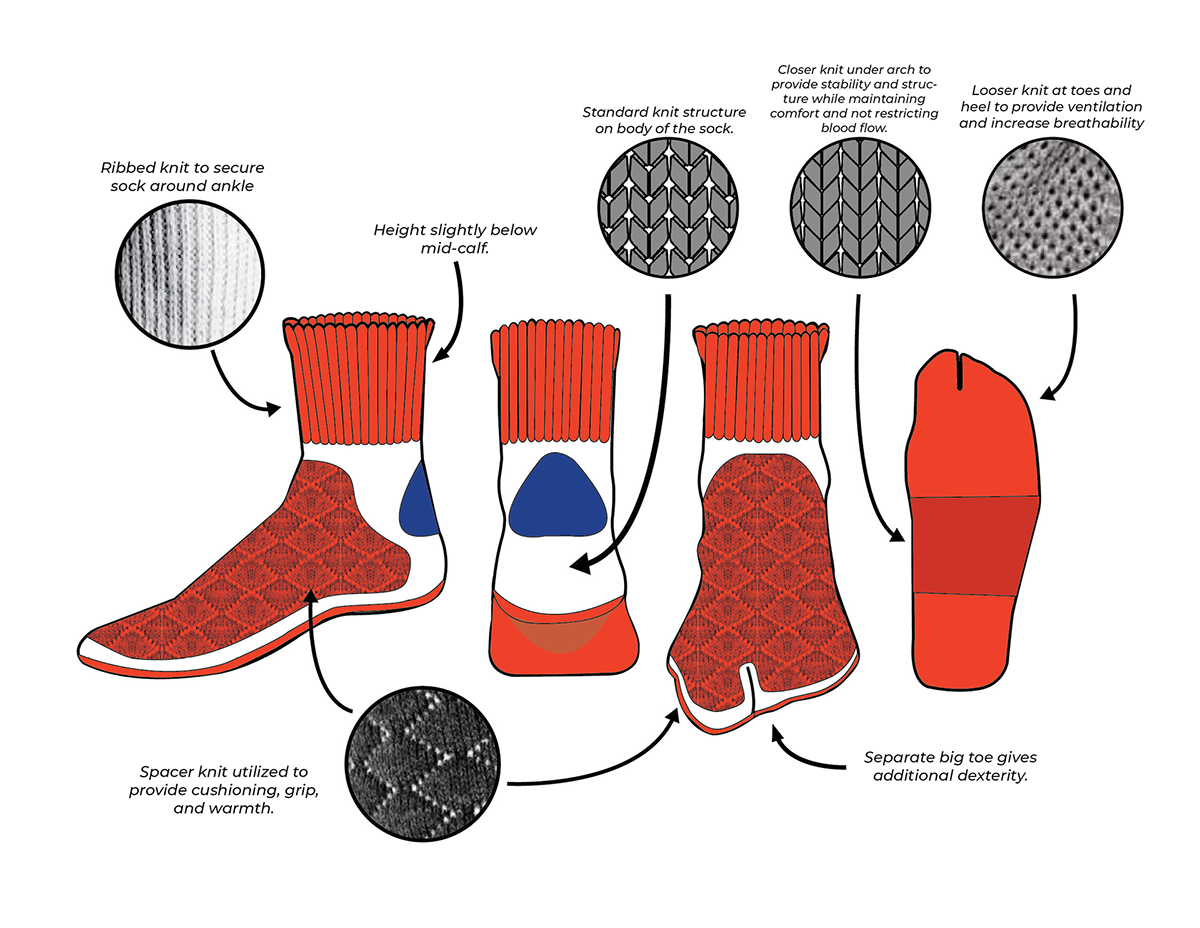

Technical illustration of the final design with call-outs to the specialized features.

The final design contains three new features that distinguish it from the previous iterations.

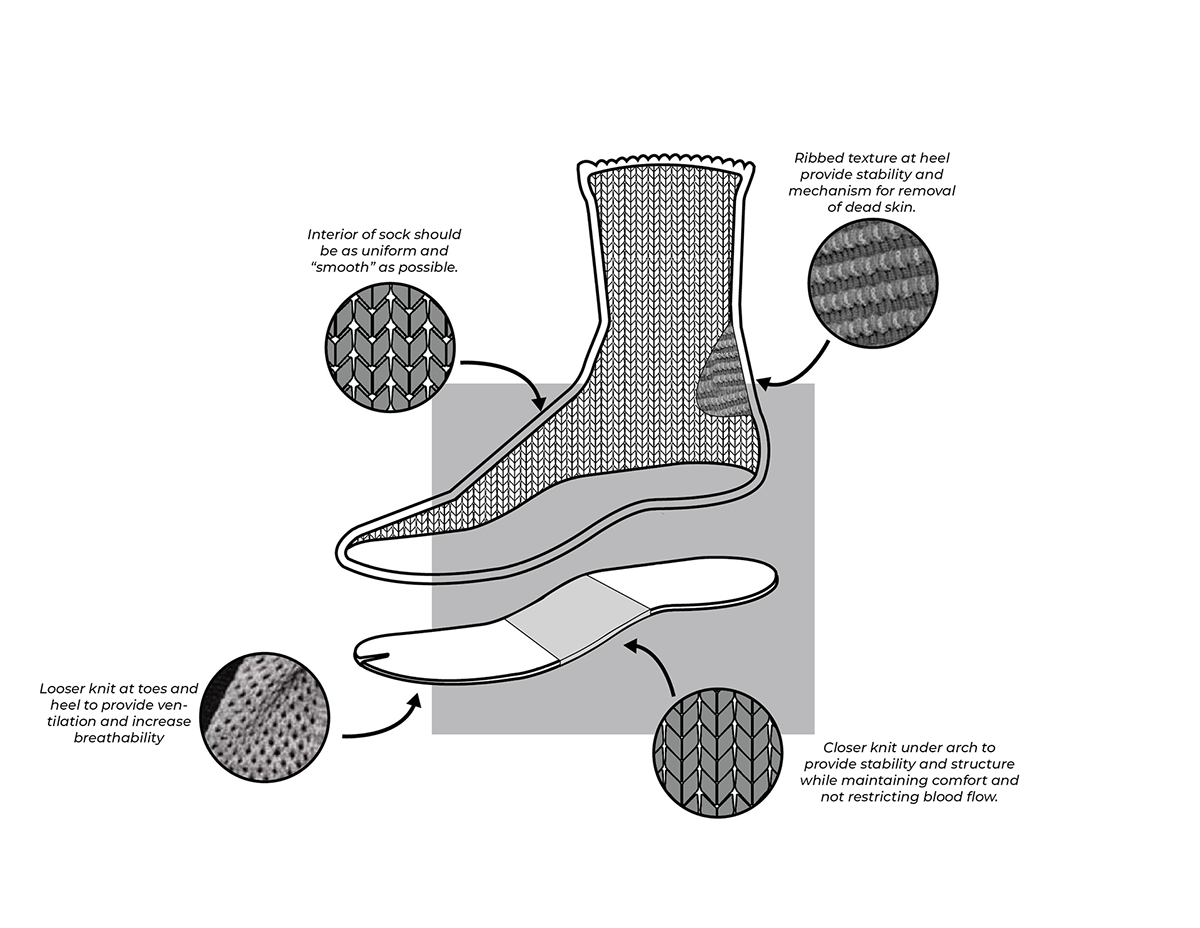

1. The padding on the top of the foot is constructed using a spacer knit technique that is frequently utilized in 3D knitting. The padding has also been expanded to under the ankle, incorporating what was formerly a separate section for grip into the overall padding structure.

2. The big toe has been separated from the other toes, like Japanese Tabi socks, as a way of making the foot a more versatile tool for the astronauts to use.

3. The patch on the back of the ankle now has a ribbed structure on its interior that acts as support and serves as a means of "scrapping" dead skin into the footwear, instead of releasing it in the air, during removal.

The idea of having a texture on the interior of the sole of the footwear as a means of preventing callus loss was dropped as its efficacy was unclear and its addition would either make it difficult to 3D knit or require the use of an uncomfortable material.

Technical illustration of the interior of the final design with call-outs to the specialized features.

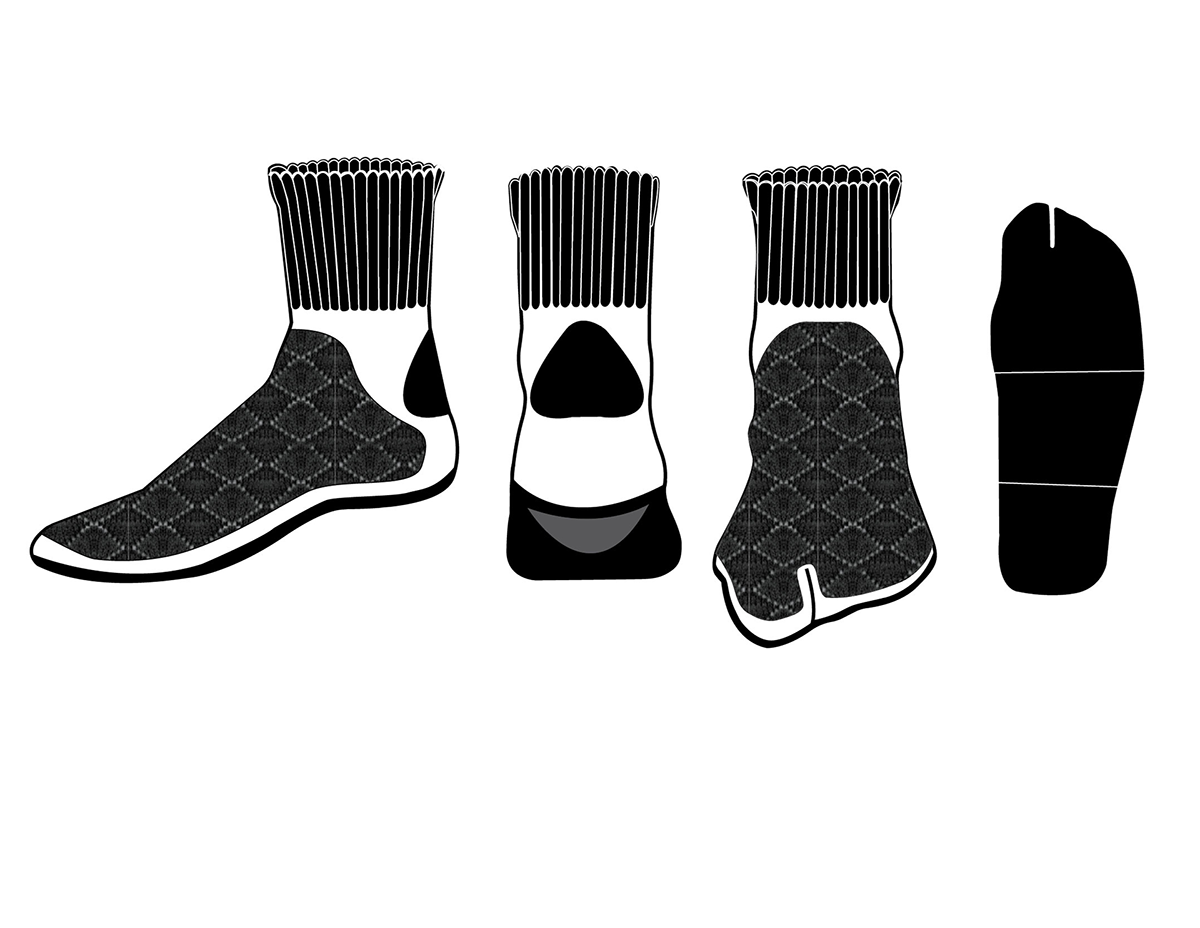

Alternative colorways.