As the final project of my Digital Fabrication class, the gear rings combine the different gear sets and digital fabrication techniques I have explored throughout Wintersession.

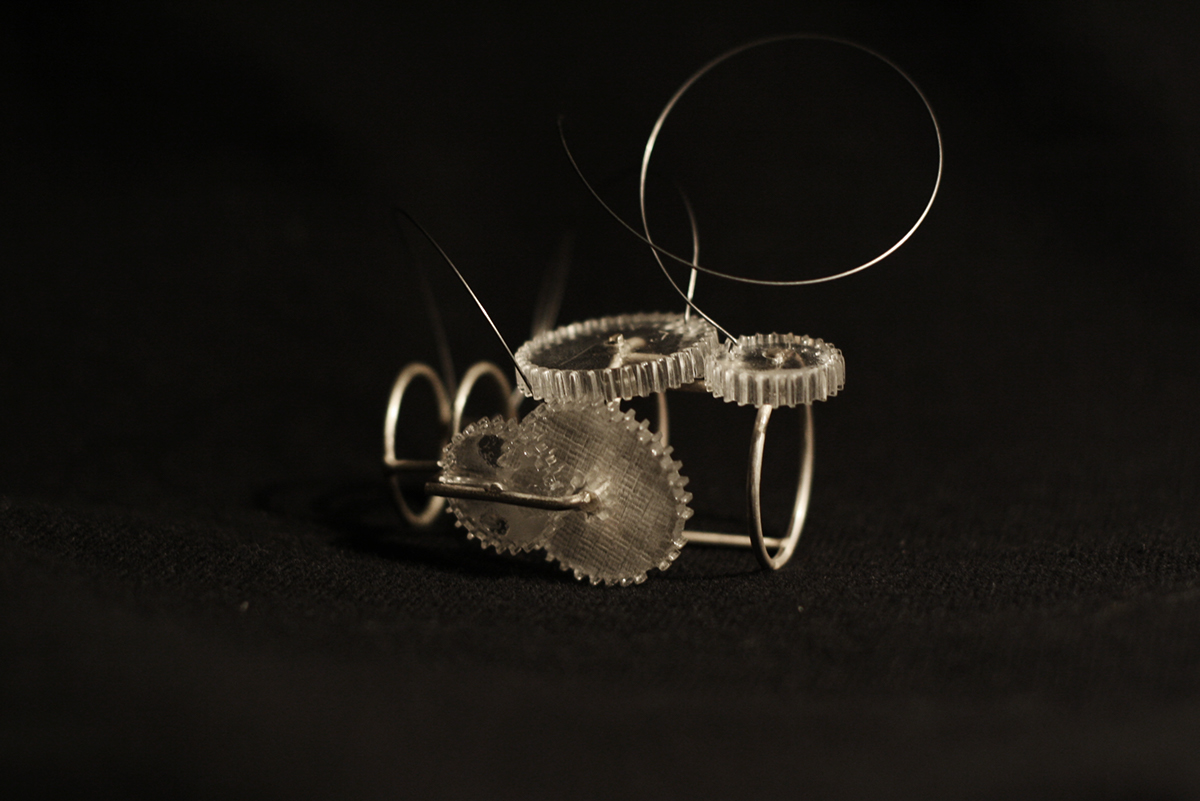

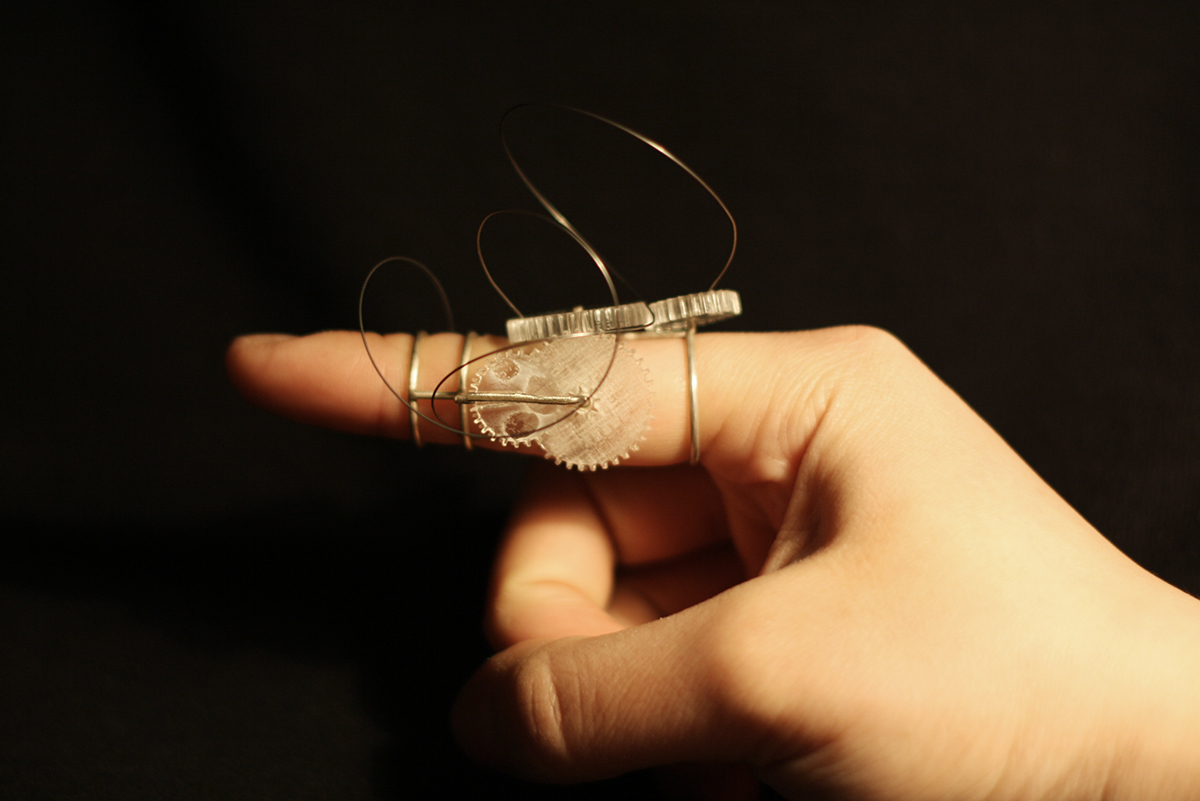

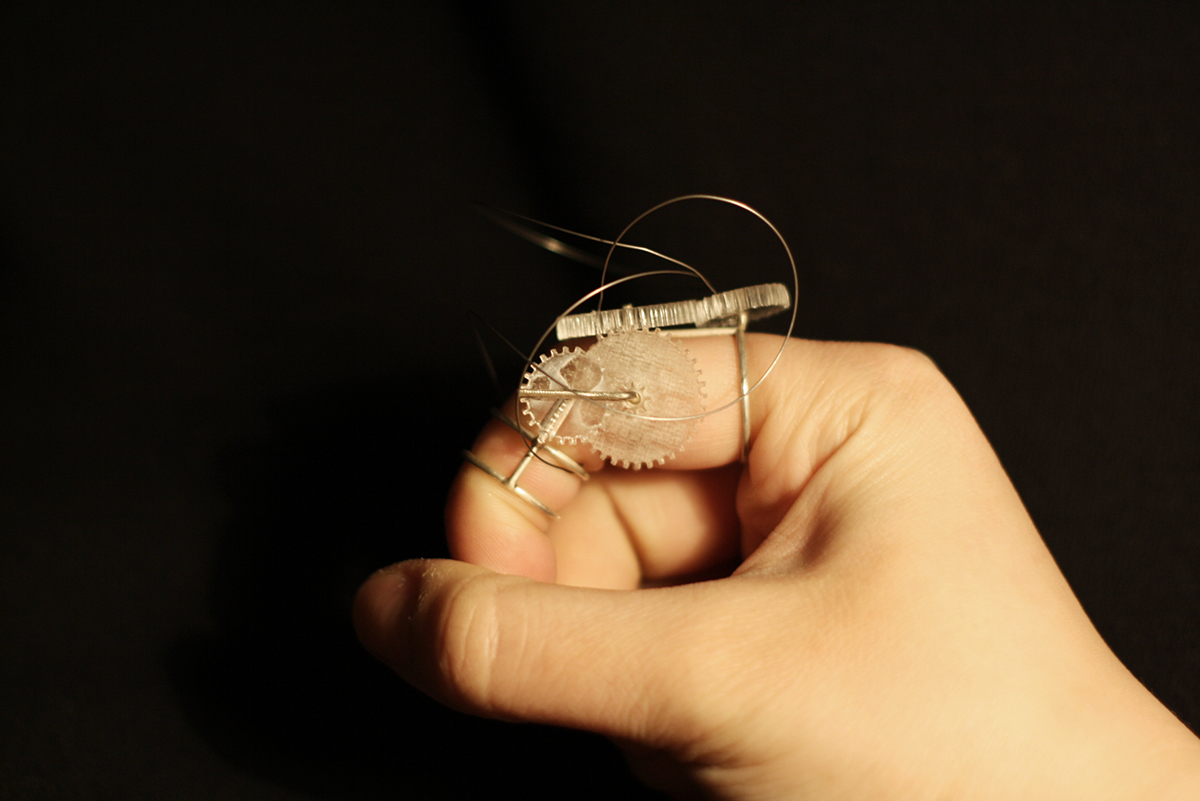

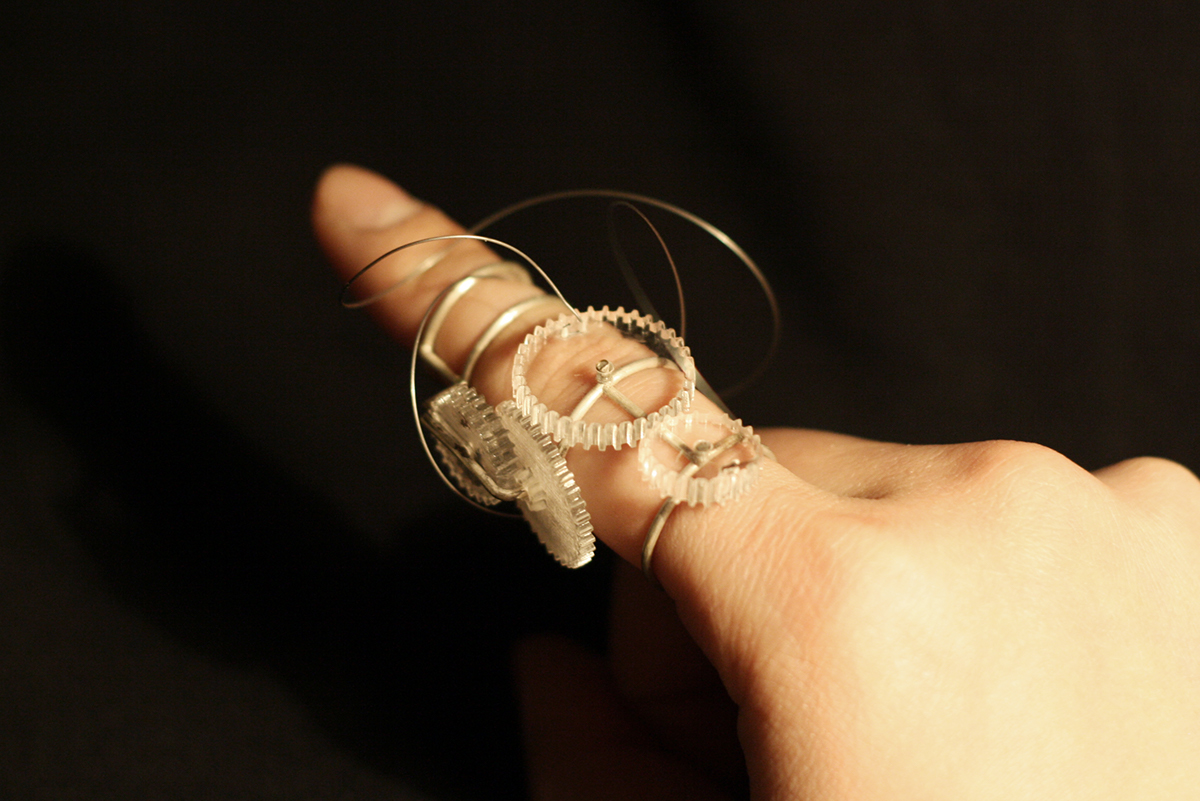

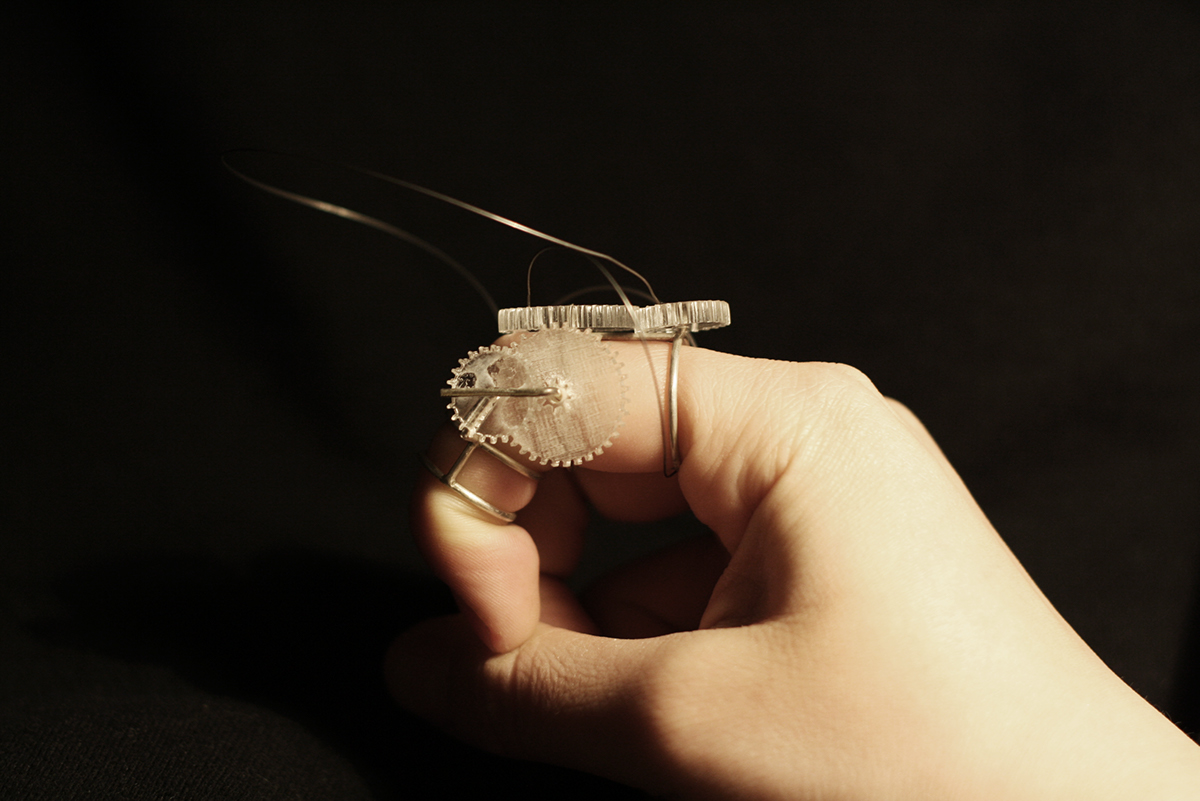

Inspired by Dukno Yoon's and Friedrich Becker's kinetic jewelry, the gear rings dynamically change and shape the space surrounding the body rather than simply adorn the body. The smaller, front ring is attached to two thin gauge piano wires, and it is detachable from the gear set on the bigger ring. The bigger ring provides the frame work and structure for the gears. The wearer have control over the orientation of the front ring, thereby changing the configuration of the wires and the distortion that is then created through movement. The bending of one's finger drives the gears - which are connected to the piano wires - into motion, distorting the shape of the wires that define the space surrounding the finger. The constant movement creates a dynamic and interactive experience for the wearer.

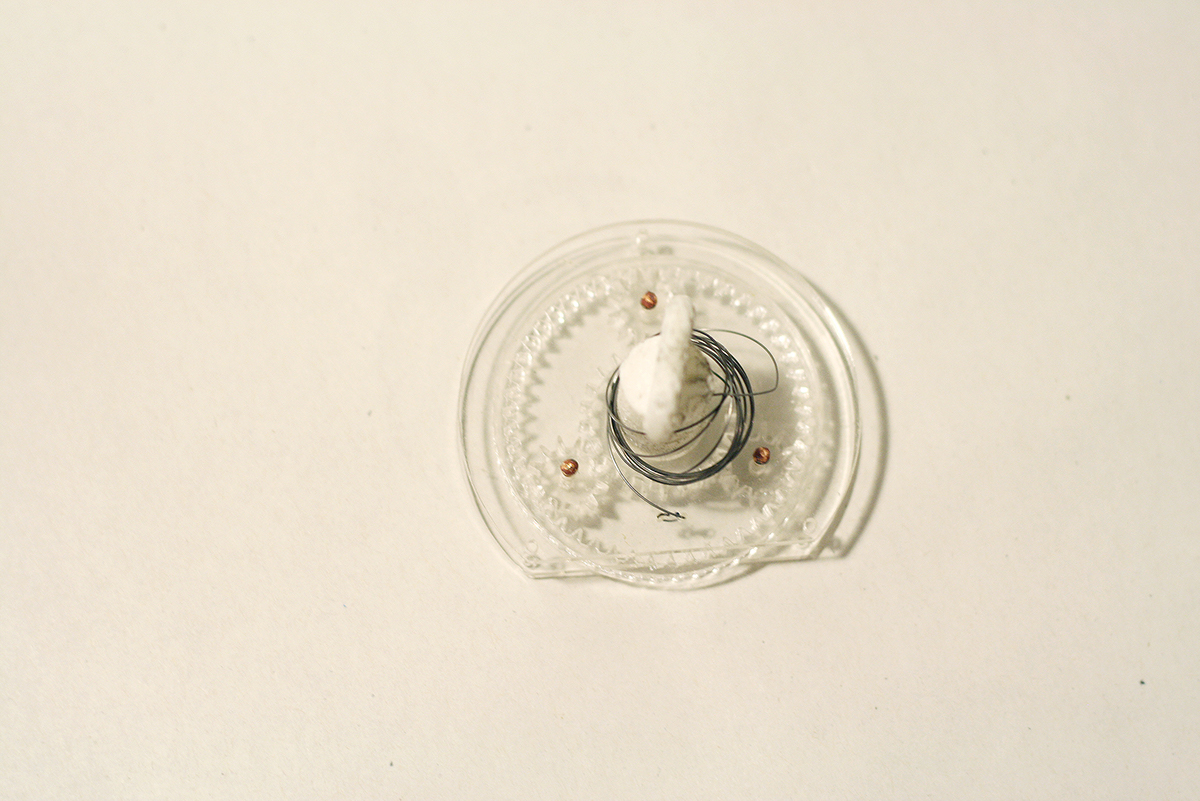

The rings also combine digital fabrication techniques and the craftsmanship in traditional jewelry. The sterling silver rings are completely handcrafted while the gears are lasercut from 1/16" and 1/8" plexiglass. Utilizing the properties of the laser cutter, one of the gears has a smaller gear rastored onto the surface, transforming a single gear to a combination of two gears with different sizes and numbers of teeth. Lasercutting is chosen over 3D printing because of its precision and the hardness of plexiglass. While 3D printing is suprerior in creating complex three-dimensional forms, lasercutting provides a higher level of precision when creating two-dimensional gears.

#1

#1 bent

#2

#2

#2 bent

#3

#3 bent

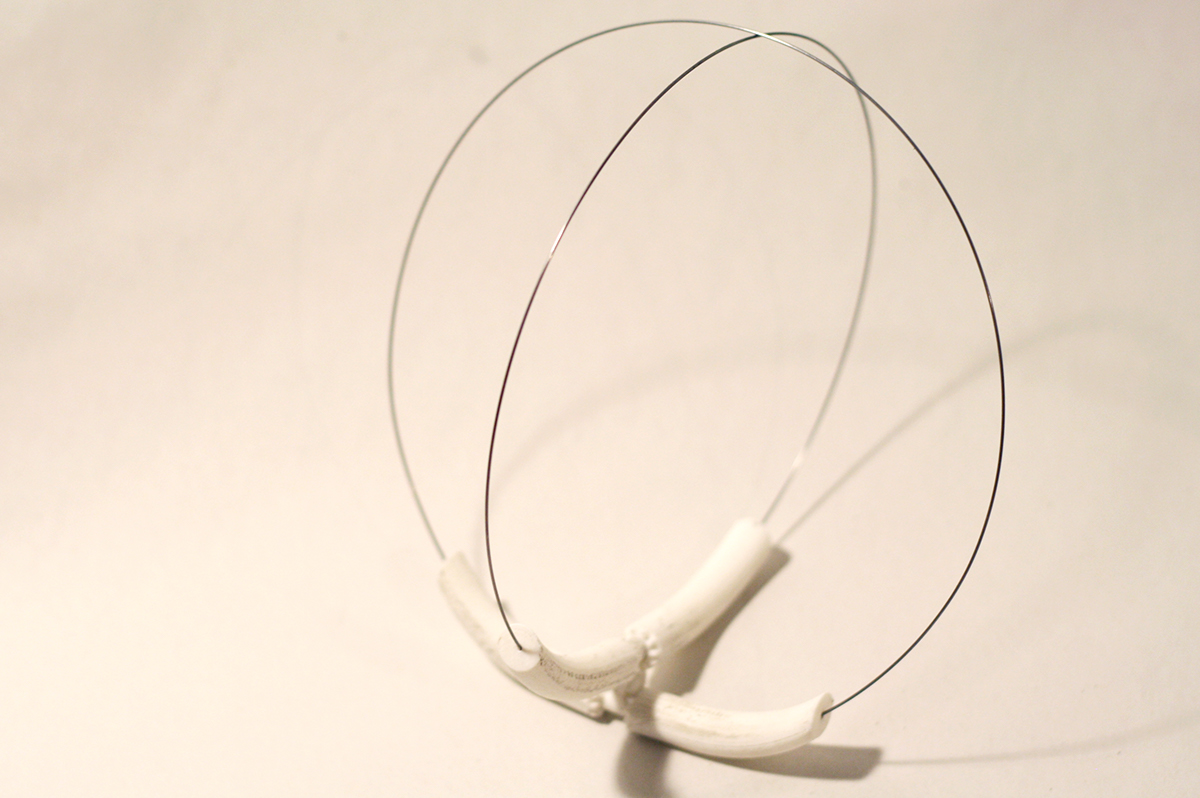

First prototype made with brass wire and a different wire frame structure for the gears.

Previous projects from the class

A planetary gear system that has a spring in the core, allowing the gears to spring back after winding up. The gears are lasercut plexiglass and riveted with brass wires, while the key is designed on Rhino and 3D printed with a Makerbot Replicator 2.

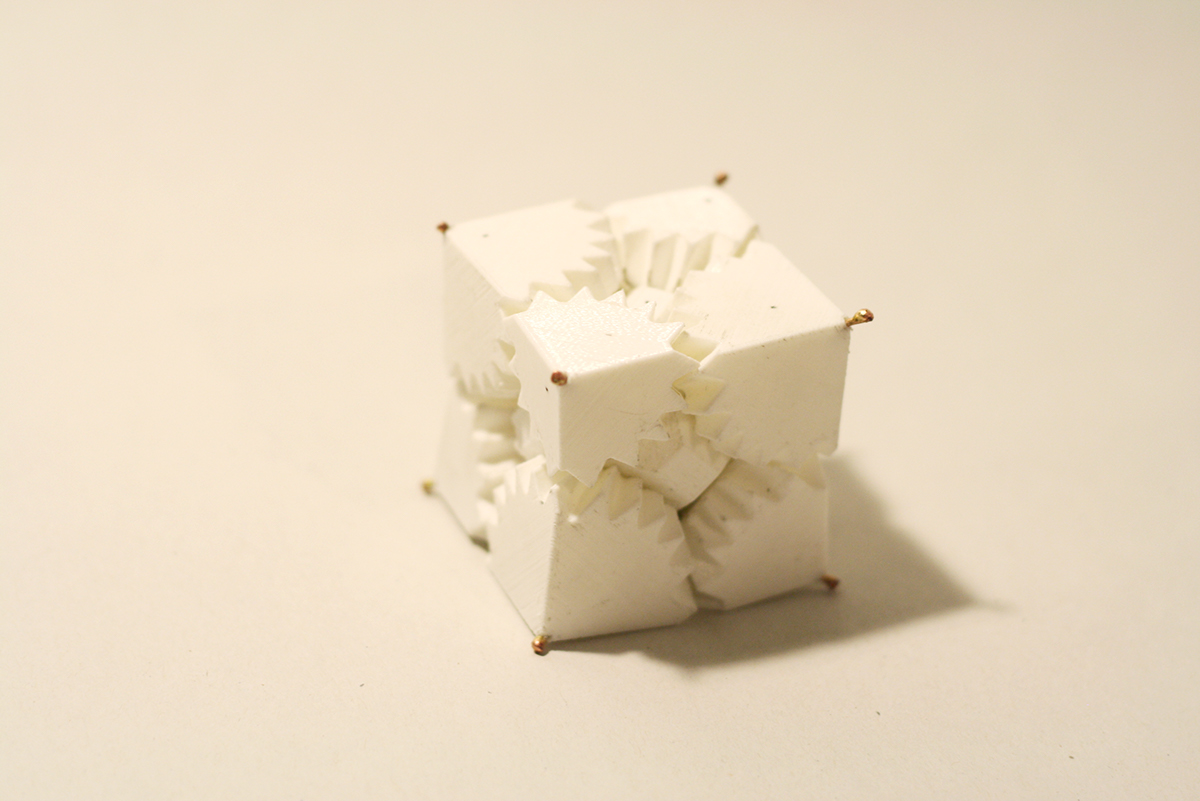

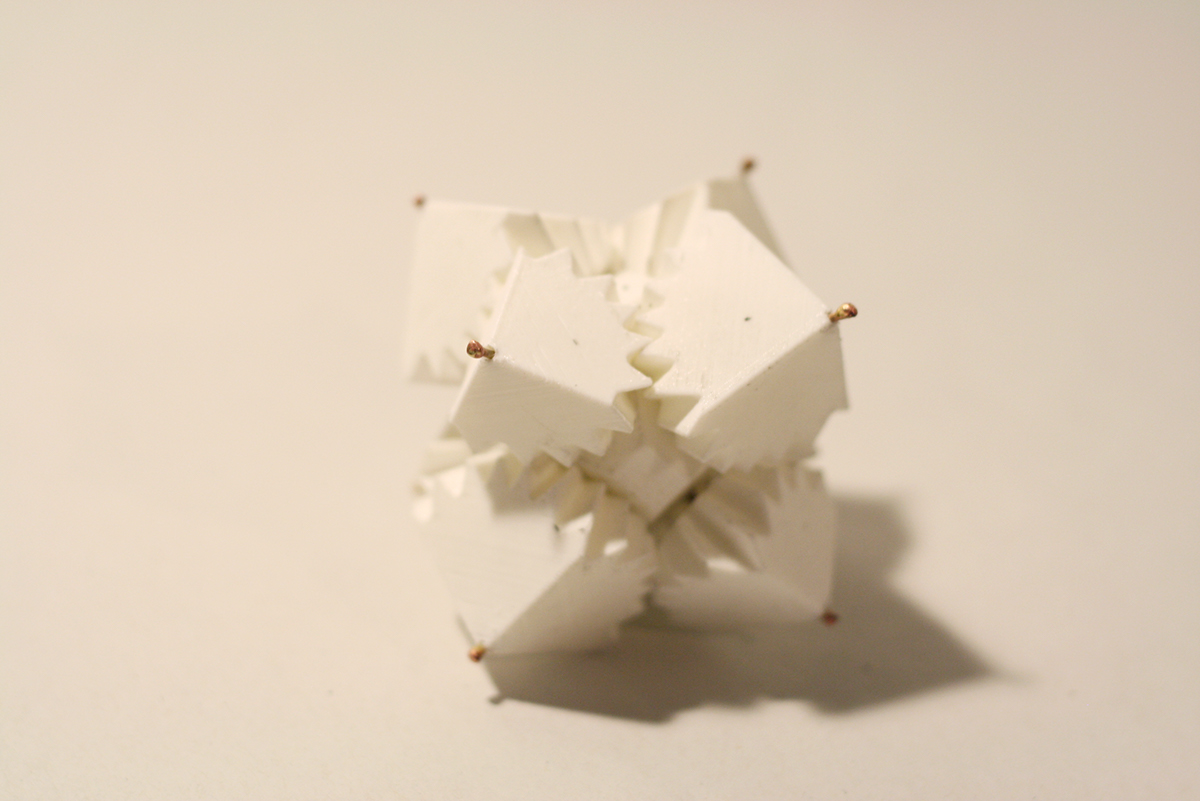

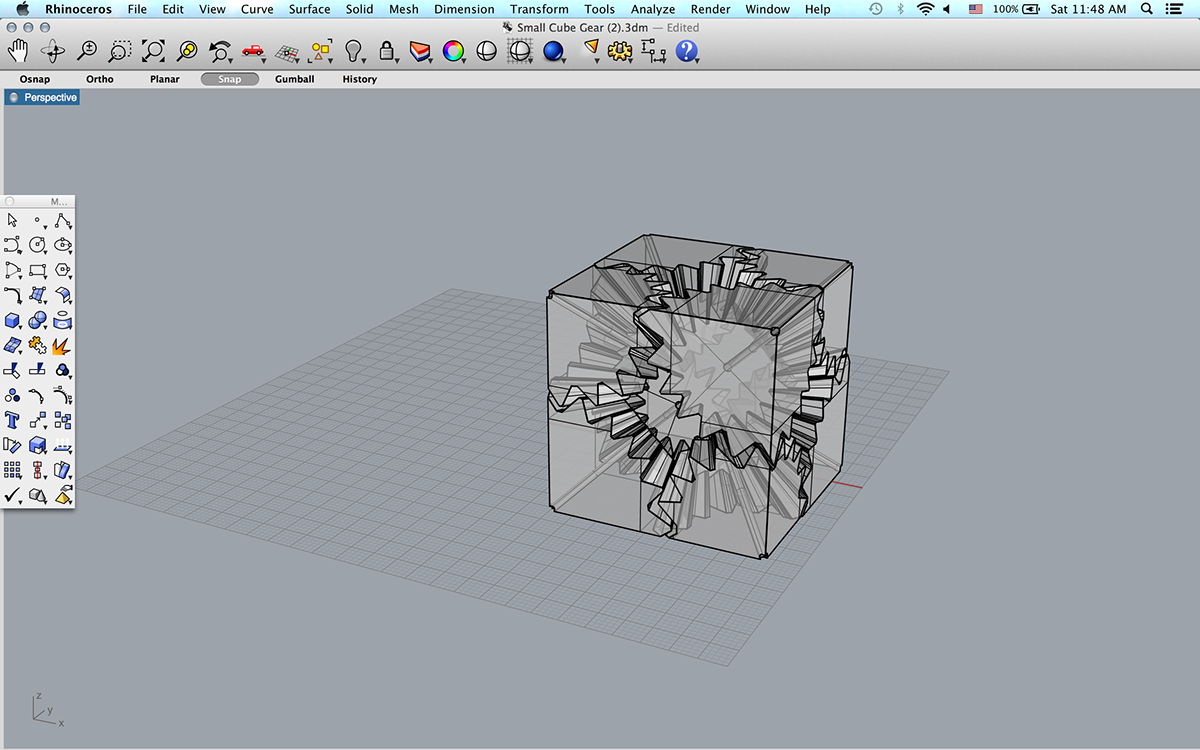

A 3D printed cube gear designed through Rhino. All parts are riveted with brass wires.

A 3D printed gear system that shapes space with the wire, the concept is revisited in the final project.