Project Studio: Design for Entrepreneurship

Team: Douglas Bjorkdal, Leah Chung, & Deesha Misra

Team: Douglas Bjorkdal, Leah Chung, & Deesha Misra

The Need

According to the American Orthopaedic Foot and Ankle Society, 55% of women in the U.S. have bunions. Yet, there are very few shoe brands in the market that cater towards this common foot deformity. There are orthopedic shoes made to accommodate bunions, but they lack in style and are generally not desireable for women who care about both comfort and style.

Our user research taught us several factors that our solution needed to embody. Some key findings are summarized in the following testimonies:

One of the most common responses from our users was that they cared about style first and foremost. Comfort was definitely important but it would always take a back seat to aesthetics. Though our challenge was in achieving a fine balance between style and comfort, we knew we had to start with tackling comfort because obviously, no one had done that yet, and especially not for the comfort of bunions. And it wasn't a matter of simply adding more padding to preexisting heels - it was a structural challenge.

Questions to Ponder

What materials would be best for shock absorption?

How can you make a wider toe box and still maintain a slim shoe?

How can you make a wedged heel and still maintain a slim shoe?

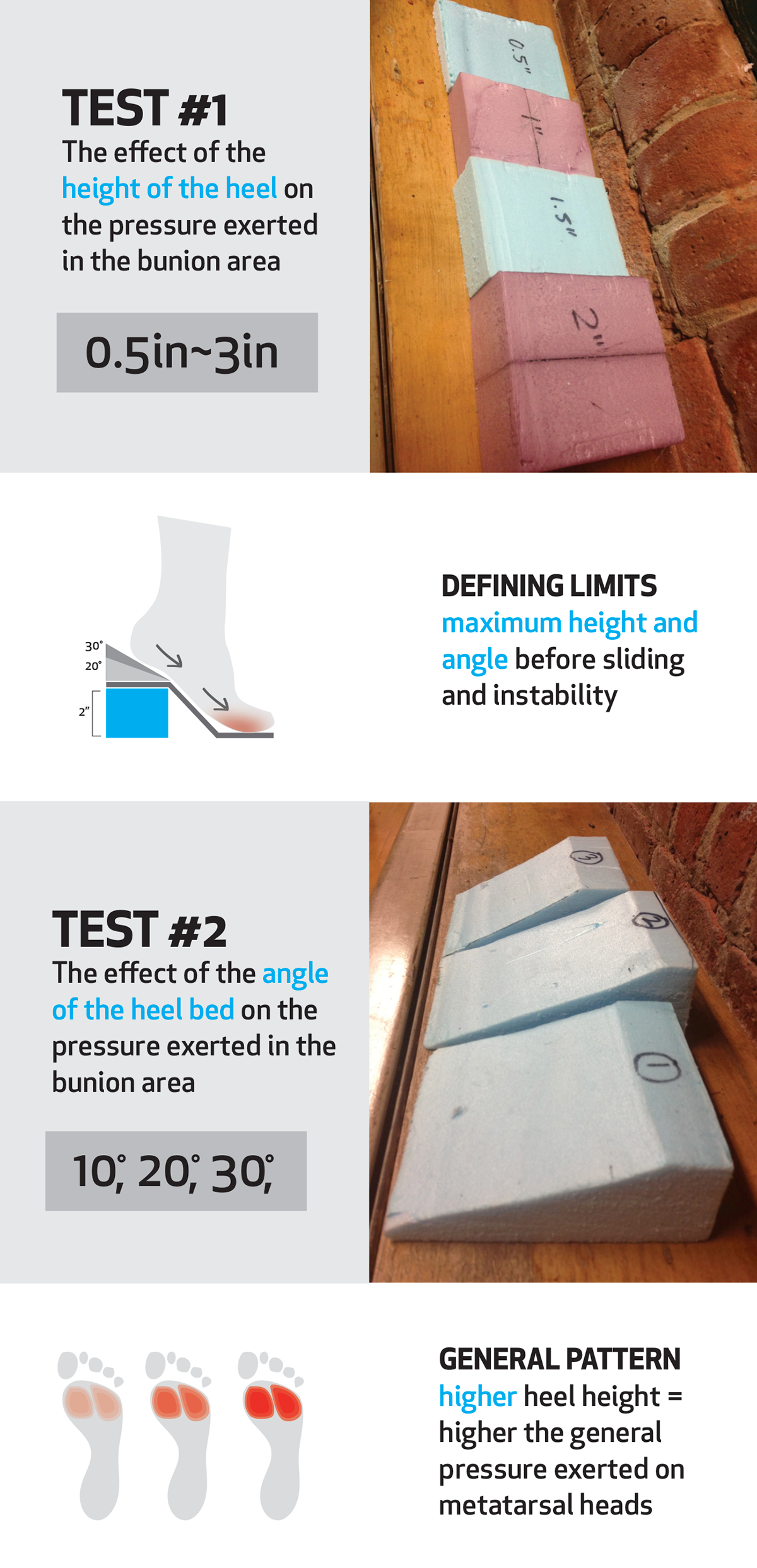

What heel height and angle would alleviate the most pressure from the balls of the feet?

Accommodative vs Functional

We were able to gain advice from a podiatrist, Dr. Mike Reuter, who advised us that our shoes could not be functional; it had to be accommodative. If it was functional, that meant we were claiming our heels would "correct" bunions - which quite frankly, no shoe could do. By being accommodative, we were claiming that our shoes would further slow bunion development, rather than fully prevent it.

The Process

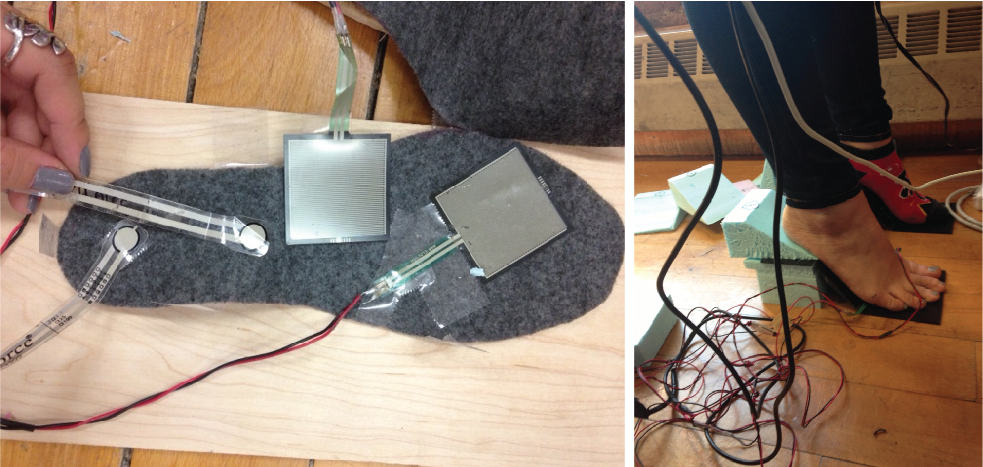

Pressure testing was utilized to gain a better understanding of how the pressure was being distributed for various heel heights and heel bed angles.

Iterations for Structure

Quick and dirty iterations were done using old heels, blue foam, fabric scraps, and lots of hot glue. These iterations were solely for the structure and comfort of the shoe and paid no attention to the aesthetics. As a bunion sufferer myself, I was the primary tester for all iterations. The notes written on the prototypes below were made after a consultation with Dr. Reuter.

Adjusted Lasts

The original high heel shoe lasts, which were very narrow and tapered, were adjusted for added width and a less steep shank angle.

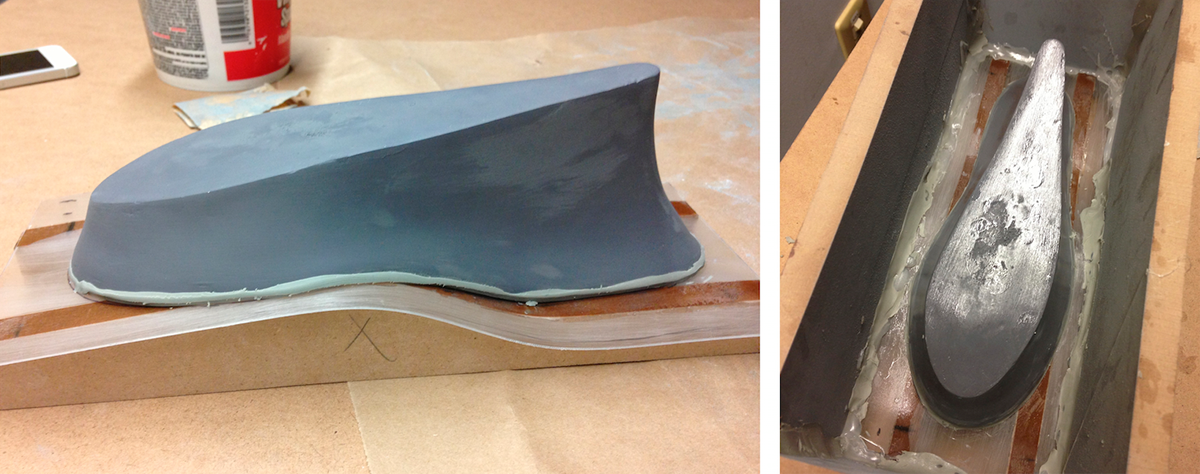

Mold-making & Casting

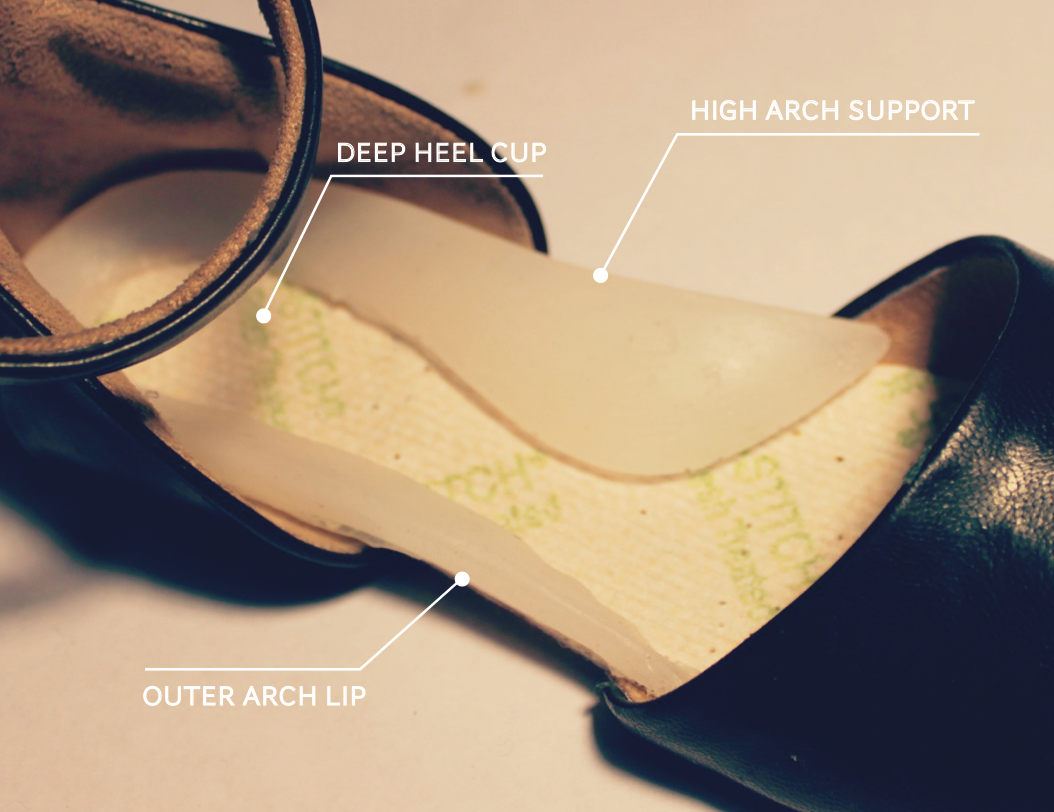

Silicone molds were made for our finalized platforms, then cast with a high-density polyurethane rubber. The models for the mold were made of blue foam and then spackled and primed. Molds were made for the silicone inserts as well. Though we did not have the time to test several materials, we chose to use polyurethane rubber to cast the entire platform for a more flexible stride as well as for true shock absorption support that was more than just a thin layer of padding. The silicone was significantly more flexible than the polyurethane, which our doctor confirmed was perfect for the inserts.

Silicone molds were made for our finalized platforms, then cast with a high-density polyurethane rubber. The models for the mold were made of blue foam and then spackled and primed. Molds were made for the silicone inserts as well. Though we did not have the time to test several materials, we chose to use polyurethane rubber to cast the entire platform for a more flexible stride as well as for true shock absorption support that was more than just a thin layer of padding. The silicone was significantly more flexible than the polyurethane, which our doctor confirmed was perfect for the inserts.

Uppers

Several iterations of the uppers were done using scrap vinyl. Each iteration was tested for comfortable fit and adequate coverage with style always in mind. The final uppers were made with goatskin and lined with ultra suede.

One of the most elastics parts of the goatskin, the shoulders, was used to cut the pattern for the toe box upper. This would give the bunions more needed stretch.

Molded Outsole

The outsole mold was 3D printed then cast with black-died polyurethane rubber, which is the same material for the heel platform.